Racer Xs Turbo Build

#32

There is a update with pictures on page 2 if anybody just came to the last page

Just trying to do my part hahaha.. No I have not tried using bolts chase was telling me that they have a tendency to come loose (or fit loose i cant rememebr) and the studs don't.

Just trying to do my part hahaha.. No I have not tried using bolts chase was telling me that they have a tendency to come loose (or fit loose i cant rememebr) and the studs don't.

#35

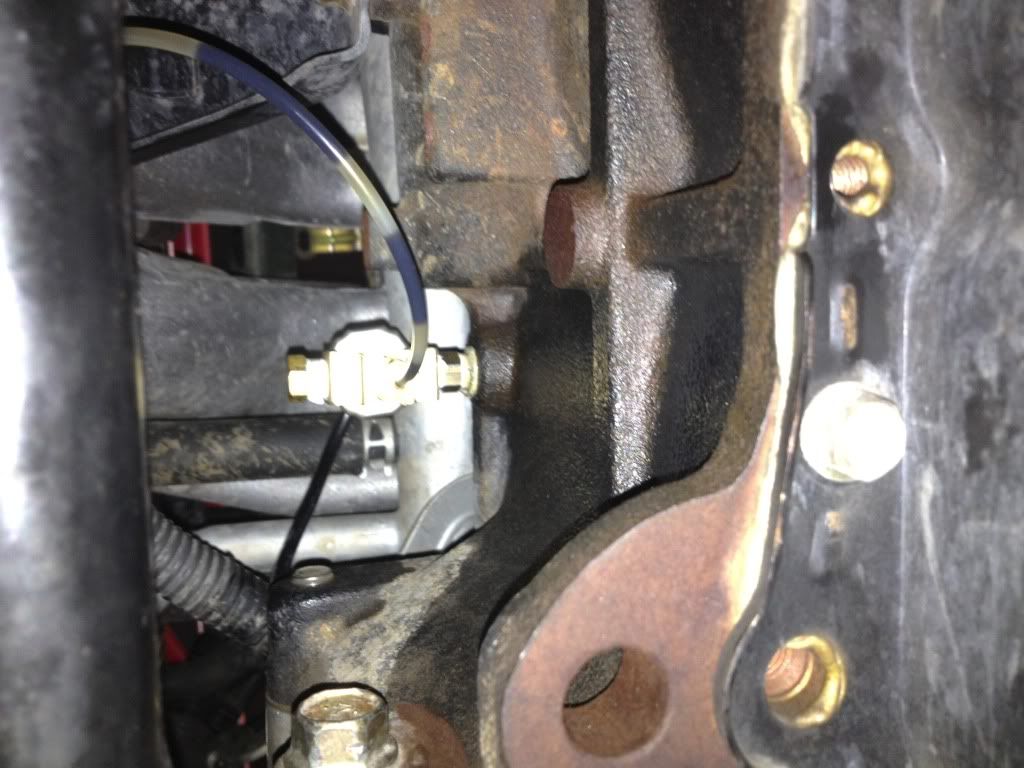

Late night update.. So after 2 times of ordering the wrong connector pins I ended up finding a whole replacement harness for my wideband and put my A pillar gauge pod together. Oil gauge is prolly going to be the only functioning gauge as all electrical has to wait until July 5th  ...

...

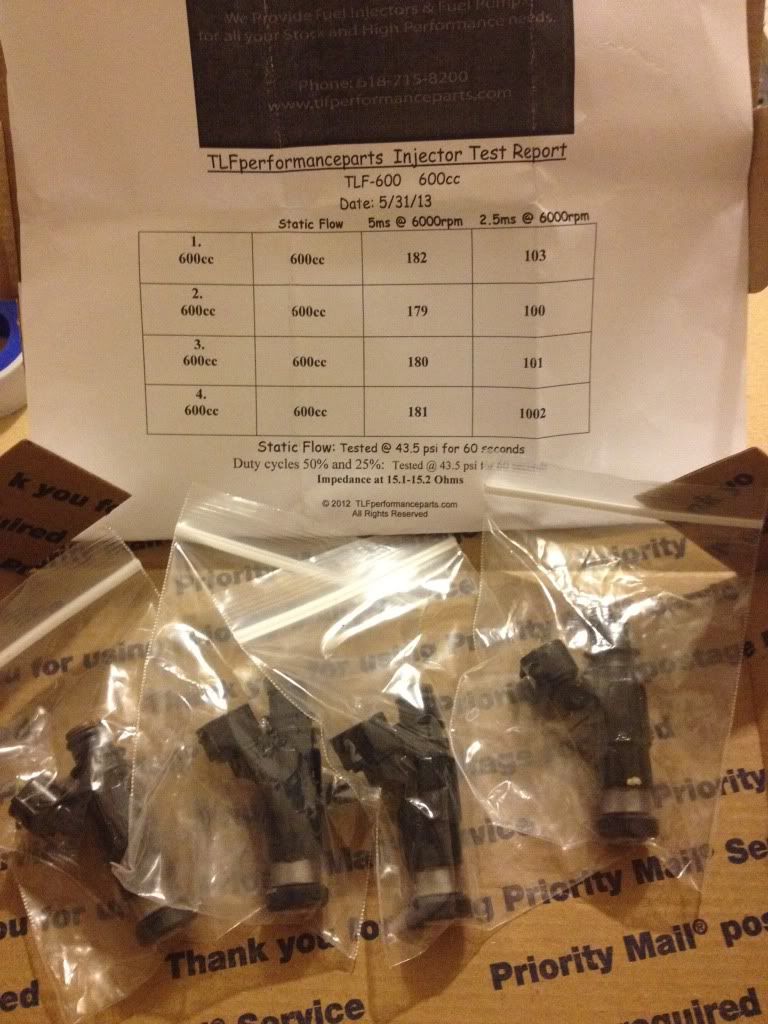

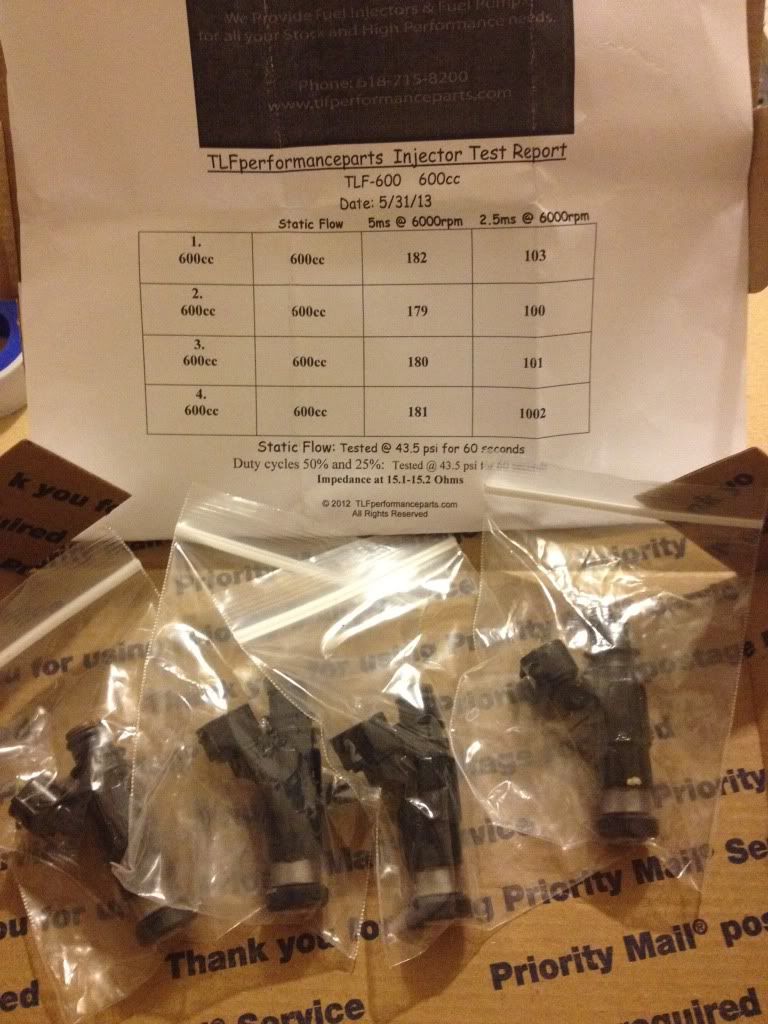

I also got these bad boys in the mail today

They are suppose to be direct replacements for the wrx's.. 600cc I know I know I didn't need to go that big of a injector but they were cheaper than the Sti pinks

...

...I also got these bad boys in the mail today

They are suppose to be direct replacements for the wrx's.. 600cc I know I know I didn't need to go that big of a injector but they were cheaper than the Sti pinks

Last edited by RacerX-Ralliart; Jun 7, 2013 at 12:49 AM.

#37

Evolving Member

iTrader: (1)

Join Date: Jan 2004

Location: Lex, KY

Posts: 234

Likes: 0

Received 0 Likes

on

0 Posts

lol, how much boost you planning on running that you're worried about boost creep? unless you plan on running a decent amount of boost through the motor, you probably won't be moving enough air to exceed the maximum flow of the wastegate. Like Ralliartize It says, if you have good exhaust flow it should be ok.

As far as the lightweight flywheel: the engine does rev quicker due to less inertia(weight), but it also means there is less inertia to transfer to the flywheel on takeoff, meaning you have to slip the clutch *slightly* more at times. I drove both an old DSM and my evo with lightweight flywheels and love them just because I like the difference in responsiveness and how quickly I can upshift (less mass means the engines spins down faster between shifts). I know a lot of people, mostly drag racers, that don't like the lightweight FW because it *feels* like they lose power between shifts when it is really just their engine falling farther down in RPM between shifts.

It's a preference thing.

#38

Evolved Member

iTrader: (5)

I slightly disagree here (yes I know its a months old post). If you are maxing out the turbo, you won't see much boost creep because very little air goes through the wastegate. If you are running very low boost through a restrictive o2 housing, you'll see lots of boost creep because it's much easier for the exhaust to exit around the exhaust wheel then through the restricted WG passage.(learned this when messing with my first DSM). If you have an external gate, or a well designed o2 housing, then creep shouldnt be a problem.

Creep is still more likely with high boost and insufficient wastegate flow. I agree with you that if maxing out the turbo, you won't get boost creep but you'll also be losing power where a larger turbo would be more efficient and probably have excessive EGT due to exhaust flow restriction at the turbine.

#39

Evolving Member

iTrader: (3)

Join Date: Jan 2011

Location: opelika alabama

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

Well if u have a dsm with a 16g (for example), you will incounter boost creep faster with a catless 3 inch exhaust than u will if u keep the cat on boost pressures lower than 20psi. Boost creep can be caused by poor manifold design, incorrect placement of a wastegate or faulty/ undersized wastgate...

O2 housings on dsm turbos dont vary in design that much..a 16g turbo with a 16g o2 housing will work fine together... dsm turbos simply are not designed to work well with engines bigger than 2.0.... the turbo its self become a restriction.

O2 housings on dsm turbos dont vary in design that much..a 16g turbo with a 16g o2 housing will work fine together... dsm turbos simply are not designed to work well with engines bigger than 2.0.... the turbo its self become a restriction.

#42

Evolved Member

iTrader: (5)

It's my understanding that boost spike initially is normal, and very common for purely mechanical boost control. I disagree that the 2.4L is too big for a 16g, 14b yes, it was used to make 220hp from a 2.0L...the big 16g was used on the Evo to make closer to 280hp on the same motor. In reality, i'm not really spiking at all, when it spools up at WOT, it actually "spikes" to 9-10psi, which my wastegate is set for 9, but it now tapers off to about 6.5 or 7psi...with the 14b it hit 8-9 and stayed there. the big 16g has a larger wastegate, so i'm not sure if that's the issue because what i'm experiencing is boost taper, which IS likely attributed to the larger displacement motor, but at 2.5psi less boost i'm making more power than the 14b.

boost creep on the other hand is an abnormal condition due to insufficient waste gate flow, which leads to more exhaust gas than intended to flow through the turbine, spinning it faster and producing more boost than intended even though the wastegate is wide open. it's like a boost spike but occurs at WOT higher in the RPM range possibly causing a lean condition and increasing the possibility of detonation.

I've read countless articles, FAQs and even actual book made of paper on the subject, i wanted to know everything before i even started the build, there's nothign wrong with my setup.

boost creep on the other hand is an abnormal condition due to insufficient waste gate flow, which leads to more exhaust gas than intended to flow through the turbine, spinning it faster and producing more boost than intended even though the wastegate is wide open. it's like a boost spike but occurs at WOT higher in the RPM range possibly causing a lean condition and increasing the possibility of detonation.

I've read countless articles, FAQs and even actual book made of paper on the subject, i wanted to know everything before i even started the build, there's nothign wrong with my setup.

Last edited by CrAnSwIcK; Jun 8, 2013 at 06:03 PM.

#43

Evolving Member

iTrader: (3)

Join Date: Jan 2011

Location: opelika alabama

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

Im not sayimg there is anything wrong with ur setup...I give mad props on engineering ur kit and what u have done for the communtiy...if u think of it this way a evo is designed factory with a. 2.0 engine and a 16g turbo w/560cc injectors...if evos go to a bigger engine size, they go to a bigger turbo and bigger fuel system.. my poimt is that if a factory 2.0 turbo car runs a bigger turbo when they increase displacement...then a factory 2.4 car should run a bigger turbo to keep from having any problems.

Its just my opinion from building turbo cars and bikes..everyones setup on here is great and I would not talk bad about anything, anyone has done.

Its just my opinion from building turbo cars and bikes..everyones setup on here is great and I would not talk bad about anything, anyone has done.

#44

Evolving Member

iTrader: (3)

Join Date: Jan 2011

Location: opelika alabama

Posts: 182

Likes: 0

Received 0 Likes

on

0 Posts

If ur boost is tappering off at high rpm's its reached its flow max..a 14b on a 2.0 makes full boost from 2800-5300 after that it tappers off.. a 16g on a 2.4 should do the same..

came out better than I thought..

came out better than I thought..