Is Walbro 255 enough

#1

Newbie

Thread Starter

Is Walbro 255 enough

From the tons of reading I've done it seems common that a modded 255 pump is good for 480-500 on e85. My question is will my setup see that limit. Don't want to get it tuned and run out of fuel but hate to spend the money if not necessary. Thanks for the help.

Set up:

03 Evo 8 Stock block

Htz green ss housing

1450 fic injectors

Hks 272 cams

Fp cast manifold, 3" exhaust no cat

3.5 i/c with ets piping

Speed density w/ 4"intake

3 port boost control

Set up:

03 Evo 8 Stock block

Htz green ss housing

1450 fic injectors

Hks 272 cams

Fp cast manifold, 3" exhaust no cat

3.5 i/c with ets piping

Speed density w/ 4"intake

3 port boost control

#2

EvoM Community Team Leader

iTrader: (60)

i wouldn't trust a modded Wally quite to 500. that would really be pushing it. then again, i tend to do things on the conservative side. it should get you close, though.

500whp on a green? i dunno about that either, though i'm not 100% familiar with FP's new stuff (again, i run my stuff on the conservative side).

500whp on a green? i dunno about that either, though i'm not 100% familiar with FP's new stuff (again, i run my stuff on the conservative side).

#3

Newbie

Thread Starter

The new htz green is a 57 lb min turbo so I'm sure it can move enough air for 480- 500 hp (dynojet) on e85. But I'm not sure that my car will see that with the stock block and mild cams.

At first I thought I'd just spend $120 and do the 450 wally to be sure I would have enough pump. But after research, to correctly install the 450 pump, it needs a rewire kit with bigger feed and return lines along with an adjustable fpr. At that point I would be as well off with a $500 double pumper.

If it's needed I'll bite the bullet but I'd much rather put that money towards getting it tuned.

At first I thought I'd just spend $120 and do the 450 wally to be sure I would have enough pump. But after research, to correctly install the 450 pump, it needs a rewire kit with bigger feed and return lines along with an adjustable fpr. At that point I would be as well off with a $500 double pumper.

If it's needed I'll bite the bullet but I'd much rather put that money towards getting it tuned.

#4

EvoM Community Team Leader

iTrader: (60)

I wouldn't shy away from the horsepower. You can make as much as you want, within reason, as long as you keep the torque down. If the turbo can make that kind of power without having to push over 30 PSI, then I say go for it. Unless you track your car .... I once ran a car on the track on E 85 and 30 psi.... turbo go boom. LOL

as for the fuel pump, a Wally 255 will do a lot more than people think it will. I got really close to 500 hp on a Dynojet with my 255.

Then again, I keep forgetting I have small cams. I think you should be able to do 500 with those cams and turbo.. Just keep an eye on that fuel pump.

as for the fuel pump, a Wally 255 will do a lot more than people think it will. I got really close to 500 hp on a Dynojet with my 255.

Then again, I keep forgetting I have small cams. I think you should be able to do 500 with those cams and turbo.. Just keep an eye on that fuel pump.

#5

Newbie

Thread Starter

Appreciate the insight kaj. I think I may give it a shot and see how far the 255 pump will take me. I suppose a rewire combined with the pressure relief mod would help push the pump even farther?

#7

EvoM Guru

iTrader: (7)

I'm running the FP 73HTA green (54 lbs/min) on E85 with a Walboro 416 (450 lph E85 version) on stock wiring. I have Kelford 272s and FIC 1050 injectors. I'm getting 475HP/425TQ (Dynojet) out the top at 95% IDC at 32 psi boost.

Note: This was not possible on the 255, even after punching in the relief valve and boosting the voltage. The 255 simply cannot generate enough flow at the high boost pressure needed to hit your target of 500 HP. The most I could squeeze out the 255 was 425 HP.

Note: This was not possible on the 255, even after punching in the relief valve and boosting the voltage. The 255 simply cannot generate enough flow at the high boost pressure needed to hit your target of 500 HP. The most I could squeeze out the 255 was 425 HP.

Last edited by CDrinkH2O; Nov 30, 2015 at 08:38 PM.

Trending Topics

#8

EvoM Community Team Leader

iTrader: (60)

I'm running the FP 73HTA green on E85 with a Walboro 416 (450 lph E85 version). I have Kelford 272s and FIC 1050 injectors. I'm getting 475HP/425TQ (Dynojet) out the top at 95% IDC at 32 psi boost. This was not possible on the 255 even after punching in the relief valve. I did not need to modify the wiring.

#9

EvoM Guru

iTrader: (7)

It's pretty simple. The top end of the rev band 6500-8500 was too lean (>12.1) and adding fuel to the map didn't richen the AFR readings on my wideband. That was when I knew I was out of pump.

95% is fine for IDC. You can actually force IDC past 100% so long as you have a pump that can keep up

#10

Newbie

Thread Starter

If I can run a walbro 450 on factory wiring and drilling the siphon only then I will definitely go that route. I was under the impression that it required an adustable fpr, larger feed and return lines and hardwire kit. Maybe that's only it your pushing the pump to its limit, which I won't be close to.

#11

EvoM Community Team Leader

iTrader: (60)

It's pretty simple. The top end of the rev band 6500-8500 was too lean (>12.1) and adding fuel to the map didn't richen the AFR readings on my wideband. That was when I knew I was out of pump.

95% is fine for IDC. You can actually force IDC past 100% so long as you have a pump that can keep up

95% is fine for IDC. You can actually force IDC past 100% so long as you have a pump that can keep up

not bad for a 255

#12

100% IDC is static, ie. open all the time. You can't hold an injector open any longer. It's like saying you're going to 120% throttle position.

Why does software allow you to do it? The ECU is actually commanding pulse width, and if you view your fuel map in PW, it makes more sense. Most platforms don't apply logic to determine engine cycle speed so you can command as much pulse width as you want. You may not actually have the engine cycle time to get it, but you can still command it. And when you start working with staged injection and you're splitting PW between two sets of injectors, the ability to go beyond 100% IDC is absolutely necessary.

The following users liked this post:

rabenne (Apr 24, 2020)

#13

EvoM Guru

iTrader: (1)

If I can run a walbro 450 on factory wiring and drilling the siphon only then I will definitely go that route. I was under the impression that it required an adustable fpr, larger feed and return lines and hardwire kit. Maybe that's only it your pushing the pump to its limit, which I won't be close to.

#15

EvoM Guru

iTrader: (1)

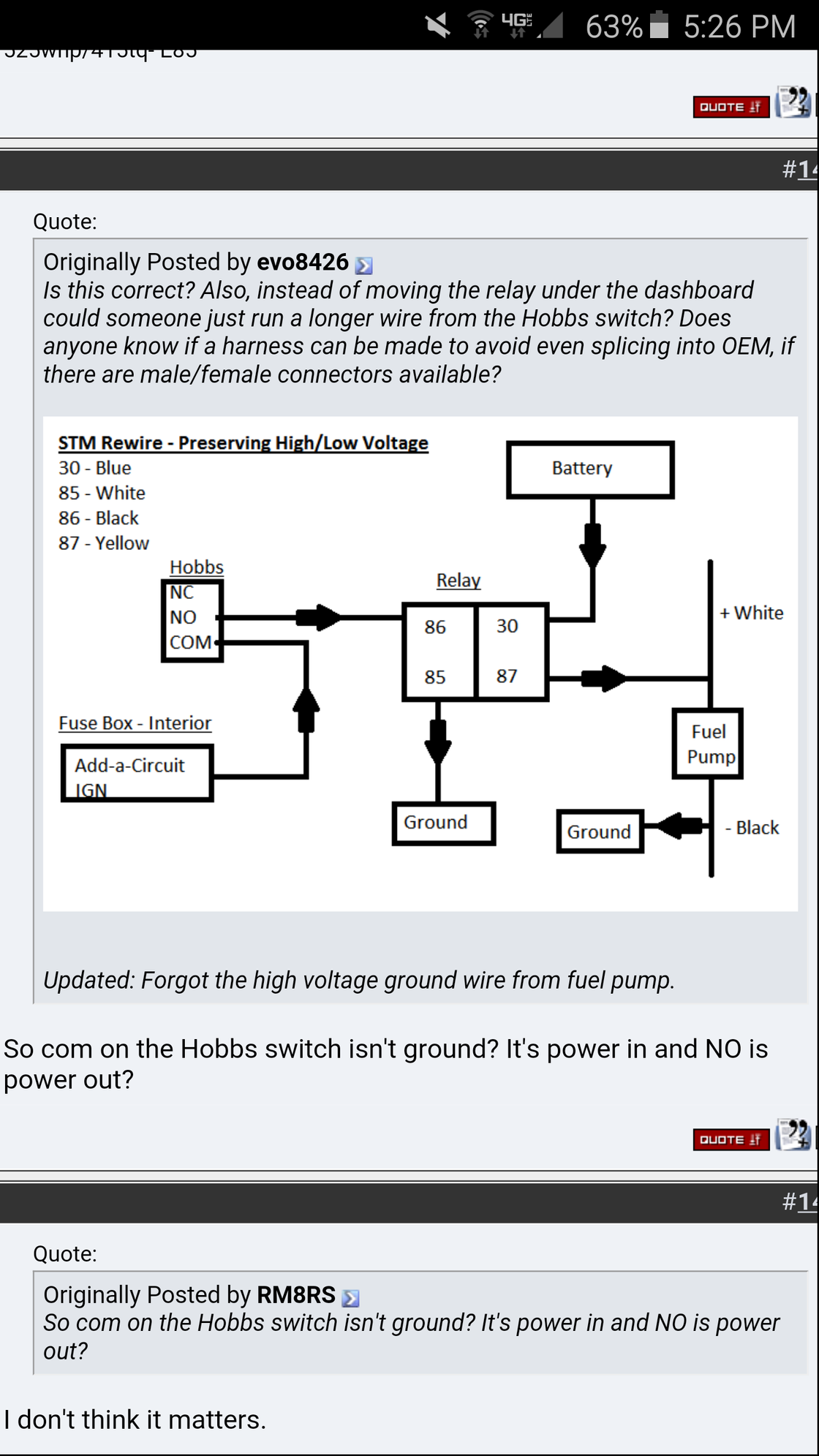

You can wire it either way. I would make the hobbs switch ground though, puts less load on it.