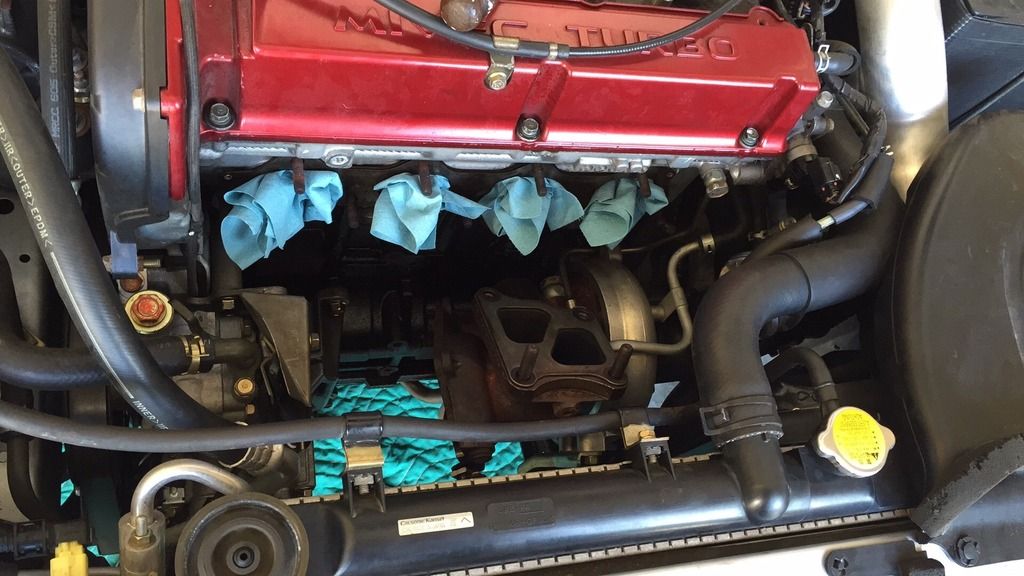

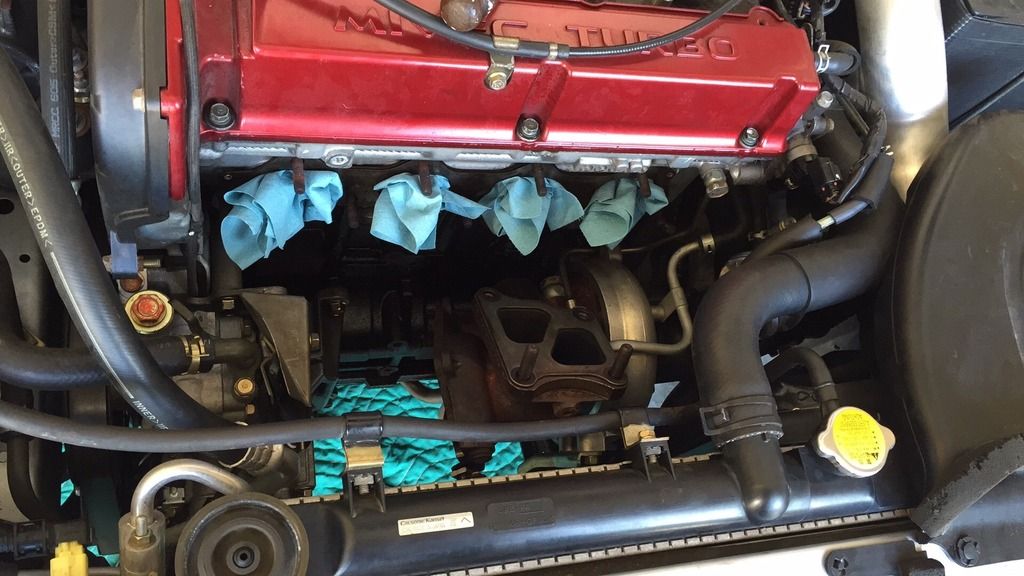

Wow... o2 housing bolt snapped into hot side.. what to do?

#1

Looking for some help.. Today decided to tackle the install of my o2 dump and ported exhaust manifold. Everything was going smooth until the very last bolt of the o2 housing wanted to be a pain to get out. Finally came out, but half of it broke off into the hot side of the turbo.

I'm sure some of you have encountered this before. If so, any tips?

Or is my only option to go ahead and remove the whole turbo setup and try an easy out kit and re-tap the hole..

Please help

The bolt that snapped is the one closest to the radiator.

I'm sure some of you have encountered this before. If so, any tips?

Or is my only option to go ahead and remove the whole turbo setup and try an easy out kit and re-tap the hole..

Please help

The bolt that snapped is the one closest to the radiator.

#2

Evolved Member

definitely something i'm not looking forward to either. if you don't have access to a torch, and/ or a 90 degree air drill, i'm afraid it does look like it has to come out. not too much you can do in that tight space. on the Brightside, the turbo is damn near out at this point. good luck.

#3

EvoM Community Team Leader

iTrader: (60)

take the v-band clamp:

http://thumbs2.ebaystatic.com/d/l225...Np3rJ06xoQ.jpg

off from the hot side/CHRA part of the turbo. the hot side comes right off with a bit of wiggling. don't worry: the CHRA stays with the cold side. it's one, whole unit. also, there is a pin/hole that you line up when it goes back together. you can't attach it wrong. when you pull it off, wiggle gently at first and pull straight out so you don't ding the fins of the wheel.

take the whole hot side to a machine shop. they will get it out for about $20. it's SO much easier than messing with it yourself. otherwise, you're in for a couple days of misery LOL

P.S. it's 1,000,000x easier installing the O2 housing while the hotside is off.

http://thumbs2.ebaystatic.com/d/l225...Np3rJ06xoQ.jpg

off from the hot side/CHRA part of the turbo. the hot side comes right off with a bit of wiggling. don't worry: the CHRA stays with the cold side. it's one, whole unit. also, there is a pin/hole that you line up when it goes back together. you can't attach it wrong. when you pull it off, wiggle gently at first and pull straight out so you don't ding the fins of the wheel.

take the whole hot side to a machine shop. they will get it out for about $20. it's SO much easier than messing with it yourself. otherwise, you're in for a couple days of misery LOL

P.S. it's 1,000,000x easier installing the O2 housing while the hotside is off.

Last edited by kaj; Aug 2, 2015 at 08:37 PM.

#4

Former Sponsor

iTrader: (94)

This is a common issue. So much heat in the hotside area that the bolts get fused (essentially) with the hotside. I've had this happen twice.

If you can find a deburring place, they have speciallty equipment for this. There is one local to me, but I don't think you're in Los Angeles.

If you can find a deburring place, they have speciallty equipment for this. There is one local to me, but I don't think you're in Los Angeles.

#5

EvoM Guru

iTrader: (1)

Wow... o2 housing bolt snapped into hot side.. what to do?

Easy solution once it's fixed is don't use the OEM stainless bolts. Stainless sucks for anything with threads. It's most of the reason the bolts gall and get stuck.

Trending Topics

#8

Evolving Member

#11

EvoM Guru

iTrader: (1)

#13

EvoM Guru

iTrader: (1)

Next time the turbo comes off, I'm going to go to a bolt shop and find some high heat fasteners that are more meant for this type of application.

Thread

Thread Starter

Forum

Replies

Last Post

pupo

Evo Engine / Turbo / Drivetrain

11

Oct 25, 2012 04:35 PM

I had this exact scenario happen on my stock snail years ago and drilling it out was no fun. Should have just dropped the hotside off at a machine shop and called it a day. Oh the memories...

I had this exact scenario happen on my stock snail years ago and drilling it out was no fun. Should have just dropped the hotside off at a machine shop and called it a day. Oh the memories...