How To: Protect Your Intercooler

#1

Evolved Member

Thread Starter

iTrader: (13)

Join Date: Jun 2003

Location: central coast CA

Posts: 1,424

Likes: 0

Received 0 Likes

on

0 Posts

this tutorial is on a TurboXS intercooler. the basics can be used on any intercooler. just follow the same steps and take your time.

okay, dont you hate all those nasty little rocks and stuff that get gathered up in your new pretty looking intercooler?? dont you also hate it when the fins get bent and now it looks like !#$#$?? well, i did this on my 98 GST Eclipse with a Greddy type 24 intercooler and worked really well. i also did this to my stock intercooler, radiator, and my wifes radiator in her Lexus IS300. let me tell you, it keeps ALOT of bugs/rocks from plugging up her A/C condenser since she does quite a bit of driving.

since their isnt a "how to" on this, i decided to document on how to protect your intercooler.

okay first off, you will need to remove your intercooler. i wont go into explaining that since there are several other threads on how to remove your front facia, piping, intercooler, etc. i will just jump to the intercooler itself. okay, here we go

for starters, you will need some aluminum screen mesh found at your local hardware store. cost me about $8.00 for the aluminum type. reason i chose aluminum is for the retention of shape, cost, and most importantly its aluminum like your intercooler. the mesh itself looks like it is better at allowing airflow through unlike the plastic/nylon type of mesh.

you will also need a straight edge of some type, a tape measure, a marker, and some ultra black silicone.

once you aquired these items it is time to make some measurements. what i like to do is make the measurements of the intercooler about 1" wider for the sides and 2"taller for the heights. more on that later...

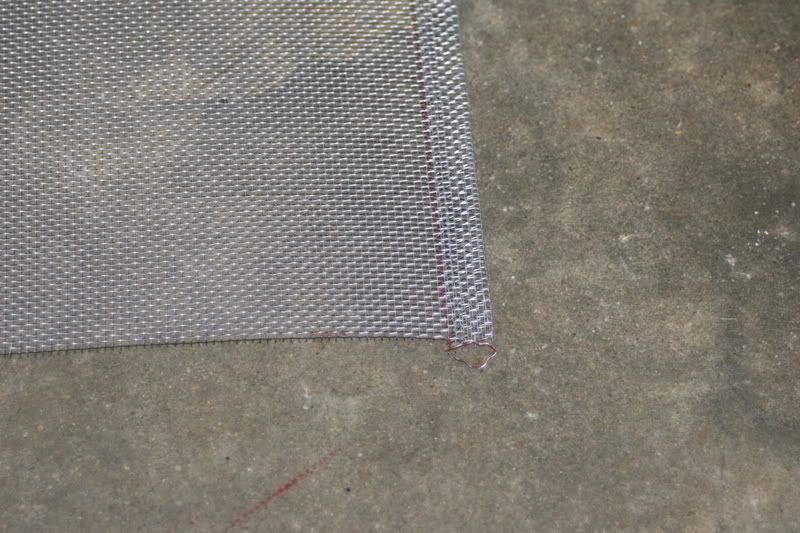

here is what you should have by now:

okay, good. i have a nice square to cut out. you can use scissors if you like(recommended). it wont damage the scissors-it will keep your cut fairly straight and uniform. if you try to use a box cutter, it will only tear up the screen. we dont want that. we want it nice and square. you will see why in the following steps.

okay, now you have it cut out. find something around the house that you can use to fold over the screen mesh with. a yard stick will do. remember i told you that i like to measure about 1" wider?? here is why:

take a measurement of 1/2" and fold over the screen. you can do this by laying the yard stick down and using your hand to just fold the screen upwards at a 90* angle first, then fold it over completely. do the same for the othe side. this will keep the edges of the screen from unraveling.

okay, dont you hate all those nasty little rocks and stuff that get gathered up in your new pretty looking intercooler?? dont you also hate it when the fins get bent and now it looks like !#$#$?? well, i did this on my 98 GST Eclipse with a Greddy type 24 intercooler and worked really well. i also did this to my stock intercooler, radiator, and my wifes radiator in her Lexus IS300. let me tell you, it keeps ALOT of bugs/rocks from plugging up her A/C condenser since she does quite a bit of driving.

since their isnt a "how to" on this, i decided to document on how to protect your intercooler.

okay first off, you will need to remove your intercooler. i wont go into explaining that since there are several other threads on how to remove your front facia, piping, intercooler, etc. i will just jump to the intercooler itself. okay, here we go

for starters, you will need some aluminum screen mesh found at your local hardware store. cost me about $8.00 for the aluminum type. reason i chose aluminum is for the retention of shape, cost, and most importantly its aluminum like your intercooler. the mesh itself looks like it is better at allowing airflow through unlike the plastic/nylon type of mesh.

you will also need a straight edge of some type, a tape measure, a marker, and some ultra black silicone.

once you aquired these items it is time to make some measurements. what i like to do is make the measurements of the intercooler about 1" wider for the sides and 2"taller for the heights. more on that later...

here is what you should have by now:

okay, good. i have a nice square to cut out. you can use scissors if you like(recommended). it wont damage the scissors-it will keep your cut fairly straight and uniform. if you try to use a box cutter, it will only tear up the screen. we dont want that. we want it nice and square. you will see why in the following steps.

okay, now you have it cut out. find something around the house that you can use to fold over the screen mesh with. a yard stick will do. remember i told you that i like to measure about 1" wider?? here is why:

take a measurement of 1/2" and fold over the screen. you can do this by laying the yard stick down and using your hand to just fold the screen upwards at a 90* angle first, then fold it over completely. do the same for the othe side. this will keep the edges of the screen from unraveling.

Last edited by badhabit90; Apr 13, 2009 at 09:18 PM.

#2

Evolved Member

Thread Starter

iTrader: (13)

Join Date: Jun 2003

Location: central coast CA

Posts: 1,424

Likes: 0

Received 0 Likes

on

0 Posts

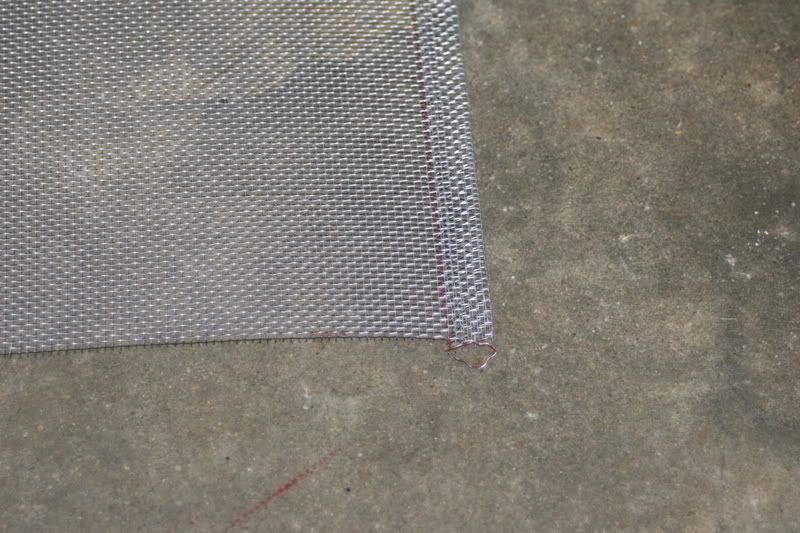

next, you will want to do the top and bottom of the screen mesh. you will be making a measurement of 1" this time and only folding it to 90*. DO NOT FOLD IT ALL THE WAY OVER!! you will be attaching it to the intercooler soon. that is in the next step. you should have something like this now...

you can take the screen and lay it ontop of your intercooler now to make any final adjustments. if you have made a measurement error, you can flatten the screen back out and readjust your marks. now is the time to make sure...

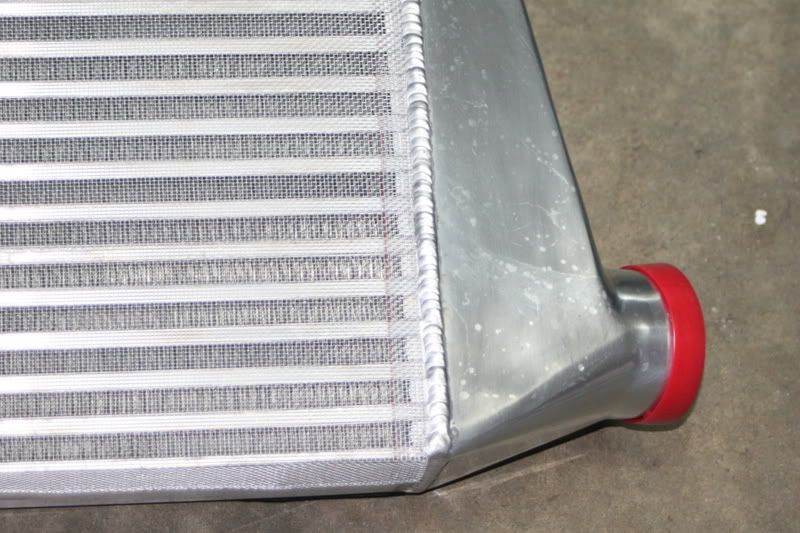

first, clean the areas along the top and bottom of the intercooler where it will be attached. i used some brake parts cleaner.

next, we are going to attach the intercooler with some high temp ultra black silicone. lay the intercooler down and lay the screen mesh over the front of the intercooler. what you will be doing is making a bead of silicone along the top and bottom of the intercooler with the screen on it. i set some extra cans on top to hold down the screen so it doesnt move. once you are comfortable with the fitment, you can start to make your bead like this:

to help make it uniform, i just ran my finger along the bead of silicone to make sure it was "suspending" the screen into the silicone.

and the bottom:

once you have done both the top and bottom, let it dry for about an hour. it will be tacky and you will be able to handle it.

i like the stock appearing look, so after about an hour, i took some appliance epoxy paint to it. i just sprayed enough to do the top side.

you can take the screen and lay it ontop of your intercooler now to make any final adjustments. if you have made a measurement error, you can flatten the screen back out and readjust your marks. now is the time to make sure...

first, clean the areas along the top and bottom of the intercooler where it will be attached. i used some brake parts cleaner.

next, we are going to attach the intercooler with some high temp ultra black silicone. lay the intercooler down and lay the screen mesh over the front of the intercooler. what you will be doing is making a bead of silicone along the top and bottom of the intercooler with the screen on it. i set some extra cans on top to hold down the screen so it doesnt move. once you are comfortable with the fitment, you can start to make your bead like this:

to help make it uniform, i just ran my finger along the bead of silicone to make sure it was "suspending" the screen into the silicone.

and the bottom:

once you have done both the top and bottom, let it dry for about an hour. it will be tacky and you will be able to handle it.

i like the stock appearing look, so after about an hour, i took some appliance epoxy paint to it. i just sprayed enough to do the top side.

Last edited by badhabit90; Apr 13, 2009 at 09:23 PM.

#3

Evolved Member

Thread Starter

iTrader: (13)

Join Date: Jun 2003

Location: central coast CA

Posts: 1,424

Likes: 0

Received 0 Likes

on

0 Posts

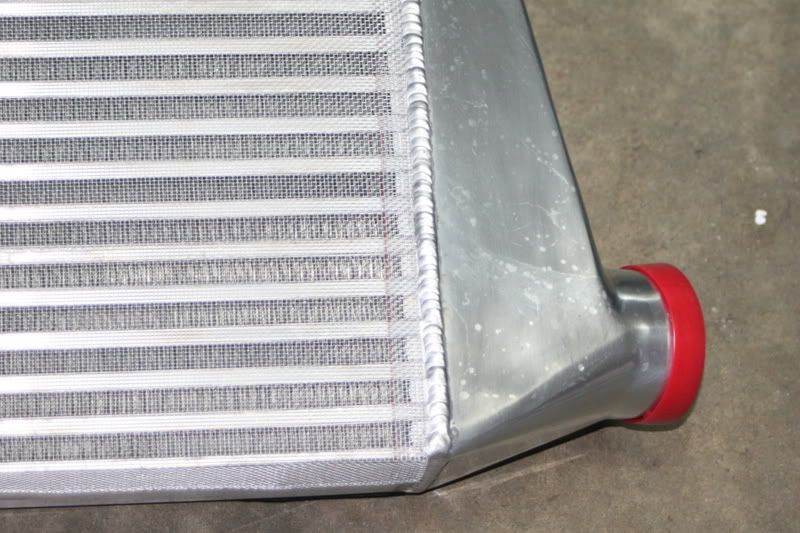

okay, once you have let the paint dry, you can handle the intercooler. here is a comparison from stock to the new front mount.

once you are happy with it and done polishing the endtanks, you can install back into the car. it should look something like this:

total time was about 4hours. this includes the time to take off the front facia if you are familiar with taking it off. if not i would add about 1 more hour to that.

good luck and i hope it was useful for you!! thanks for reading!!

once you are happy with it and done polishing the endtanks, you can install back into the car. it should look something like this:

total time was about 4hours. this includes the time to take off the front facia if you are familiar with taking it off. if not i would add about 1 more hour to that.

good luck and i hope it was useful for you!! thanks for reading!!

Last edited by badhabit90; Apr 13, 2009 at 09:28 PM.

#6

Evolved Member

iTrader: (5)

Join Date: Aug 2005

Location: Florida

Posts: 1,878

Likes: 0

Received 0 Likes

on

0 Posts

Holy cow, where do you live? The front of my car and my FMIC has never seen that much debris and bugs...

But anyway, i just wanted to throw in that those people who are interested in painting their intercoolers black to be more "stealth" or whatever, can probably just do this mod and paint the aluminum mesh black, i'm sure it would greatly reduce the shine of the FMIC. Not to mention avoiding the "will painting my intercooler damage it?" question.

Just and idea.

But anyway, i just wanted to throw in that those people who are interested in painting their intercoolers black to be more "stealth" or whatever, can probably just do this mod and paint the aluminum mesh black, i'm sure it would greatly reduce the shine of the FMIC. Not to mention avoiding the "will painting my intercooler damage it?" question.

Just and idea.

Trending Topics

#8

Evolving Member

iTrader: (15)

Join Date: Aug 2004

Location: Iowa

Posts: 107

Likes: 0

Received 0 Likes

on

0 Posts

Protect your intercooler

I did a version of this by using similar black screening over the top of the Musubishi oil cooler and radiator openings. It looked stealth and kept all of the heat exchangers very clean. This was great. When I went to Buschur's shop and he said to get that junk off the car. I thought he was nuts. Then I remembered that I was having oil over heating proplems at the track and no one else was reporting these same problems. Dave also said that the screening really reduces the intercooler efficiency. So, I removed the screening before my next track day. I had no oil over heating problems whatsoever. So, as usual Dave was right. Unless you want to give up some performance and increase the chance you will have over heating of one sort or another you should not do this. If this was such a great idea, all of the manufacturers would use screened openings in their grills to keep their various heat exchangers clean. Not one car make does this because they all know the same thing that Dave knows. It will dramatically reduce air flow through the oil cooler, radiator, and intercooler and thus is a bad idea. I am sorry to rain on your parade. But I have been there and done that.

#11

EvoM Community Team

iTrader: (15)

Yeah I def would not do this. The amount of airflow you are losing to the intercooler alone is terrible, not to mention the tiny amount of air thats going to make its way to the radiator and engine bay. Poorly designed intercoolers that are too dense will see the same problems....

It may not be obvious till you hit the track, but it IS affecting you every day. I might even go as far as to say it could lower your gas milage if the Tstat stayed open to try to cool things down all the time.

And for anyone who wants to paint your FMIC, don't do it either, look into a coating (AMS offers one) that will help it shed heat, they usually look semi-flat black also.

It may not be obvious till you hit the track, but it IS affecting you every day. I might even go as far as to say it could lower your gas milage if the Tstat stayed open to try to cool things down all the time.

And for anyone who wants to paint your FMIC, don't do it either, look into a coating (AMS offers one) that will help it shed heat, they usually look semi-flat black also.

#13

Evolved Member

iTrader: (4)

Join Date: Aug 2006

Location: FLA-HI-SoCal

Posts: 1,466

Likes: 0

Received 0 Likes

on

0 Posts

Yea I would diffinetly not do this! You drasticly reduce temps by 50% or more.

Working in the fire dept. you learn that knocking out a screen can help ventalate through a window by 50%.... so go figure

Working in the fire dept. you learn that knocking out a screen can help ventalate through a window by 50%.... so go figure

#14

Evolved Member

Thread Starter

iTrader: (13)

Join Date: Jun 2003

Location: central coast CA

Posts: 1,424

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by silverghost

I did a version of this by using similar black screening over the top of the Musubishi oil cooler and radiator openings. It looked stealth and kept all of the heat exchangers very clean. This was great. When I went to Buschur's shop and he said to get that junk off the car. I thought he was nuts. Then I remembered that I was having oil over heating proplems at the track and no one else was reporting these same problems. Dave also said that the screening really reduces the intercooler efficiency. So, I removed the screening before my next track day. I had no oil over heating problems whatsoever. So, as usual Dave was right. Unless you want to give up some performance and increase the chance you will have over heating of one sort or another you should not do this. If this was such a great idea, all of the manufacturers would use screened openings in their grills to keep their various heat exchangers clean. Not one car make does this because they all know the same thing that Dave knows. It will dramatically reduce air flow through the oil cooler, radiator, and intercooler and thus is a bad idea. I am sorry to rain on your parade. But I have been there and done that.

thats why i didnt use the black screen or nylon type of mesh. race teams use this type of aluminum or stainless mesh to keep things out of their oil coolers and radiators. take a look closer next time at a ALMS Corvette and look at the inlets in the front. you dont notice them, but they are there. just like we have the mesh now, only some ALMS cars use a smaller diameter type of mesh. a particular Porsche race team i was talking to at Laguna Seca were using this on their oil coolers. that is where i got the idea. i asked them if they had any problems with cooling and they said they didnt. same with some of the Mazda cars that were on the track.

i have driven very spirited here locally and have never seen my oil temp overheat. they typically stay between 170-200f. i think that the TYPE of mesh that was used may have played a factor in your overheating issue. the size of the mesh is what will determine your flow. would you not agree?? as you can see in the pics that the aluminum mesh i used will not DRASTICALLY affect the airflow or charactaristics of the aluminum IC.

manufactuers DONT do this, well, because you are right. it is a bad idea. because it protects their parts that wont need replacing when they get a big rock, filled up with crud, or some wise azz that forgot to put out the "loose gravel" sign. it also costs them money to make and install. not very cost effective for them. im sure that there are some things that you would like to see on your car that arent there. remember, the space shuttle is built by the lowest bidder.

manufactuers DONT do this, well, because you are right. it is a bad idea. because it protects their parts that wont need replacing when they get a big rock, filled up with crud, or some wise azz that forgot to put out the "loose gravel" sign. it also costs them money to make and install. not very cost effective for them. im sure that there are some things that you would like to see on your car that arent there. remember, the space shuttle is built by the lowest bidder.

Originally Posted by o-townFLA

Yea I would diffinetly not do this! You drasticly reduce temps by 50% or more.

Working in the fire dept. you learn that knocking out a screen can help ventalate through a window by 50%.... so go figure

Working in the fire dept. you learn that knocking out a screen can help ventalate through a window by 50%.... so go figure

Originally Posted by cfdfireman1

You just cut the cooling in half.

Originally Posted by fostytou

Yeah I def would not do this. The amount of airflow you are losing to the intercooler alone is terrible, not to mention the tiny amount of air thats going to make its way to the radiator and engine bay. Poorly designed intercoolers that are too dense will see the same problems....

It may not be obvious till you hit the track, but it IS affecting you every day. I might even go as far as to say it could lower your gas milage if the Tstat stayed open to try to cool things down all the time.

And for anyone who wants to paint your FMIC, don't do it either, look into a coating (AMS offers one) that will help it shed heat, they usually look semi-flat black also.

It may not be obvious till you hit the track, but it IS affecting you every day. I might even go as far as to say it could lower your gas milage if the Tstat stayed open to try to cool things down all the time.

And for anyone who wants to paint your FMIC, don't do it either, look into a coating (AMS offers one) that will help it shed heat, they usually look semi-flat black also.

i will agree with you on the poorly designed intercoolers. internal i do believe is what is going to cause the "airflow" to be poor. the "heat exchange" is also going to be effected.

i will agree with you on the poorly designed intercoolers. internal i do believe is what is going to cause the "airflow" to be poor. the "heat exchange" is also going to be effected. i dont think this will affect my gas milage by keeping my TSTAT open longer to cool things down. remember that the Evo runs rich in the morning to warm things up when they are cold...that is when the TSTAT is closed. i gained more HP when my Mustang was in closed loop. when it was in open loop, it would give more fuel to try to warm things up faster. it ran better at the track also. this is a fully built track car.

i also agree with NOT painting your IC because you will ruin the "heat exchange" efficiency of the intercooler to the open airflow. the BEST way is to get your IC anodized as this actually penatrates the aluminum for better conductivity for heat exchange.

if you dont agree with doing this, then dont do it. simple eh?? if it helps protect my intercooler for 50,000 miles at the expense of the external flow of 2cfm, then it is worth it.

thank you and goodnight....

#15

Evolved Member

Thread Starter

iTrader: (13)

Join Date: Jun 2003

Location: central coast CA

Posts: 1,424

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by KOEvo

Holy cow, where do you live? The front of my car and my FMIC has never seen that much debris and bugs...

dont know whats worse, having these guys critique me on "airflow" or "you just cut your cooling 50%" or an intercooler COMPLETELY filled with those little bastard bugs...wheres the efficiency with that?? with the mesh, i can wash them off BEFORE the plug my intercooler.

we get alot of bugs here when it is hot. little bastards are everywhere. really screws your day up when you wash, wax, and go for a cruise. THEN you get pelted with all of these little damm things flying around. ESPECIALLY the bees...