Tuning for faster spool

#31

Evolved Member

iTrader: (8)

I actually went up to 2 degrees advanced and that's where it saw considerable top end losses but picked up mid range. 1 degree just got lost in run to run variance when testing.

It been awhile since I looked but these FP/Comp 280+ cams seemed like that had pretty low overlap. I'd have to look around to find the cam cards though.

It could just be related to the fast ramp rates and short advertised duration of these cams. Either way, for overall powerband, FP got it right. 0/0 FTMFW

#32

Evolved Member

iTrader: (55)

Wastegate preload helps. A nice aftermarket wastegate helps during spool. Smaller intake cam.

#33

Evolved Member

Thread Starter

iTrader: (22)

Join Date: Nov 2003

Location: Northern KY near Cincy

Posts: 2,408

Likes: 0

Received 6 Likes

on

6 Posts

I loved when I would put change in the lower cubby and take off quick.....the change would jump into the cup holder.....PRICELESS!

I agree about the smaller intake cam. My Revolvers make great torque. The point of my discussion here it to get our "tuners" out there to give some insight into what is being done to make more power in our cars. Frankly, I am getting sent PMs all of the time to help someone tune their car. By having a better knowledge base of "How To" these tuning rookies can try to do more on their own.

Think of this as one "little guy" helping another. Heck, tunes are not cheap and times are tough....lol.

I agree about the smaller intake cam. My Revolvers make great torque. The point of my discussion here it to get our "tuners" out there to give some insight into what is being done to make more power in our cars. Frankly, I am getting sent PMs all of the time to help someone tune their car. By having a better knowledge base of "How To" these tuning rookies can try to do more on their own.

Think of this as one "little guy" helping another. Heck, tunes are not cheap and times are tough....lol.

#35

Evolved Member

Thread Starter

iTrader: (22)

Join Date: Nov 2003

Location: Northern KY near Cincy

Posts: 2,408

Likes: 0

Received 6 Likes

on

6 Posts

Here is a trick I learned from my drag racing days years ago in HS.

Rotational mass is the engines enemy. By replacing heavy pulleys with lightweight aluminum you allow the engine to spin faster and easier. Problem with the Evo is that the only company that makes a full set of pulleys is Unorthodox and they are not cheap. A full set of pulleys will save several pounds in rotational mass and free up a ton of torque.

As for tuning to get better spool and more torque I found that a little more fuel goes a long way in making more torque.

On the topic of aluminum....why doesn't more turbo companies make compressor wheels out of aluminum? Saves a ton of rotational mass....turbos will spin easier and much faster.

Is there any company out there that makes ball bearing replacements for the stock size turbo bushings?

Rotational mass is the engines enemy. By replacing heavy pulleys with lightweight aluminum you allow the engine to spin faster and easier. Problem with the Evo is that the only company that makes a full set of pulleys is Unorthodox and they are not cheap. A full set of pulleys will save several pounds in rotational mass and free up a ton of torque.

As for tuning to get better spool and more torque I found that a little more fuel goes a long way in making more torque.

On the topic of aluminum....why doesn't more turbo companies make compressor wheels out of aluminum? Saves a ton of rotational mass....turbos will spin easier and much faster.

Is there any company out there that makes ball bearing replacements for the stock size turbo bushings?

#38

Evolved Member

iTrader: (6)

I wonder if the magnesium evo 9 compressor wheel ever became reliable. I heard about failures, but only in 2005, shortly after they were released.

d

#39

Evolved Member

iTrader: (11)

There are a lot of UK companies that have used Titanium compressor wheels. Also you could send your turbo to the UK companies that converts Mitsu turbos to dual ball bearing. It would be like having a FPRED spool faster than a evo 8 turbo.

Sometimes porting and opening up flow (i.e bigger IC) slows response and "spool". Focus more on how quick your car revs out other than full spool by **** Rpm. TQ moves the mass HP keeps it going. Depending on your mod timing is what will achieve what you want.

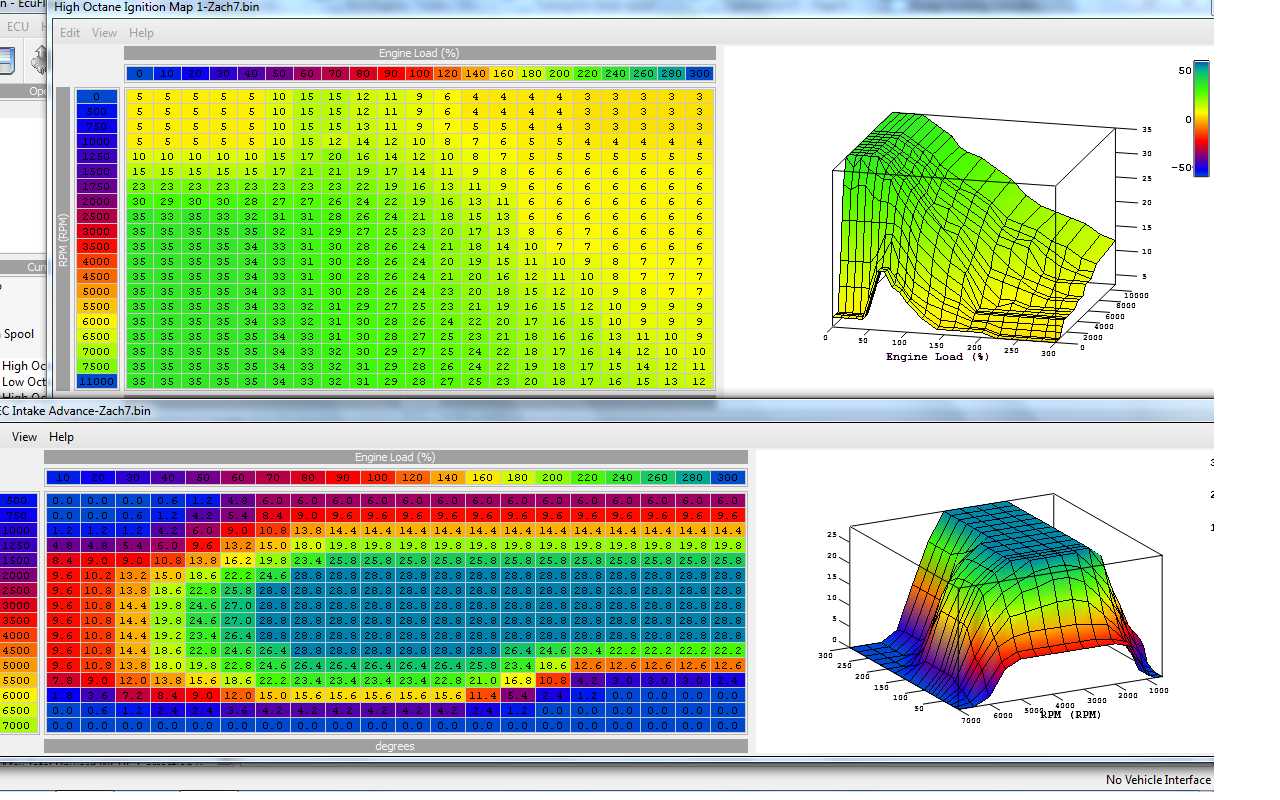

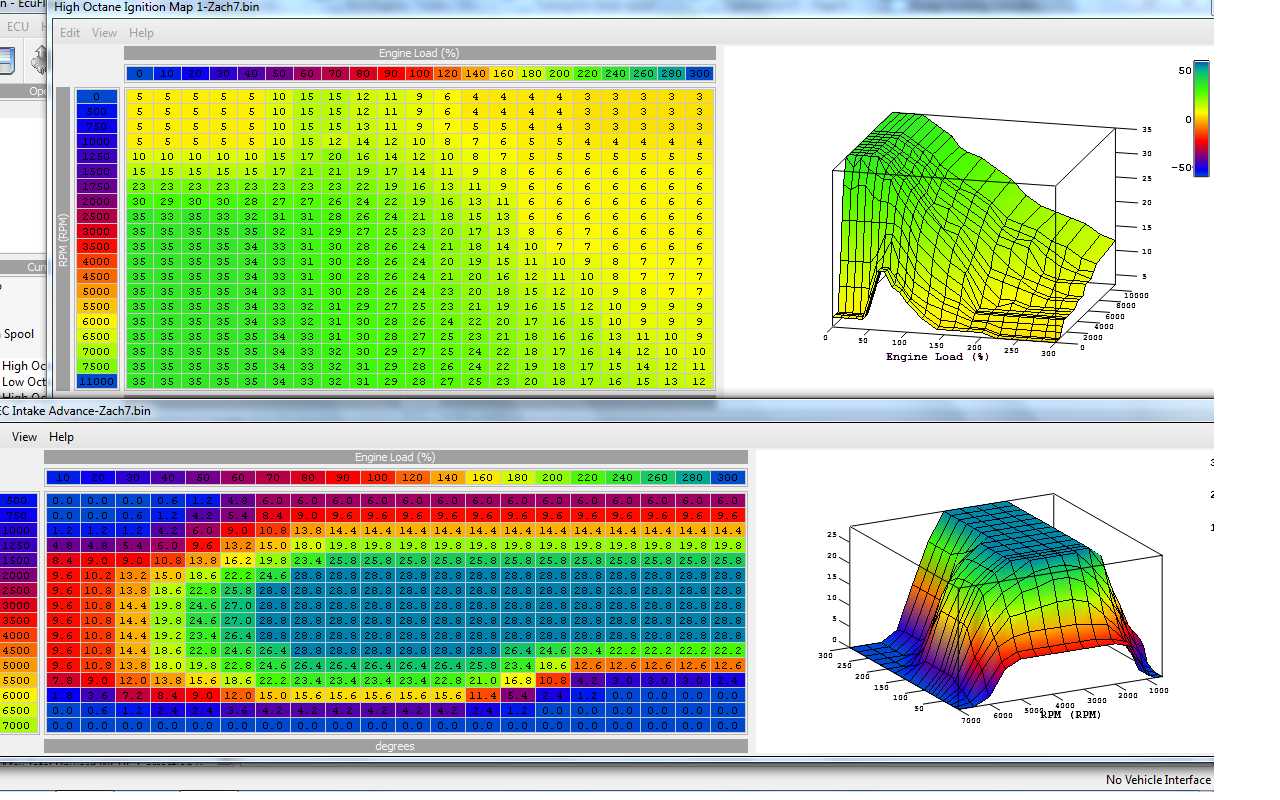

Here is a Evo 9 91oct 28 psi with a 50/50 injection timing map. This thing is FAST! This car still using Lean spool which I use on every car I tune.

Sometimes porting and opening up flow (i.e bigger IC) slows response and "spool". Focus more on how quick your car revs out other than full spool by **** Rpm. TQ moves the mass HP keeps it going. Depending on your mod timing is what will achieve what you want.

Here is a Evo 9 91oct 28 psi with a 50/50 injection timing map. This thing is FAST! This car still using Lean spool which I use on every car I tune.

#40

If one to maybe 3 hundred rpm spool (UK results) is worth the $$$ for the conversion then yeah send your turbo to UK for BB cartridge. I briefly looked into this a while back but read on the UK Evo forums that dyno testing proved that for most the $$$ did not justify the faster spool.

PS Rumor has it some of the turbo modifiers are/were working on a more cost efective BB converted standard frame style turbo. Who knows how/if progress or still being considered.

PS Rumor has it some of the turbo modifiers are/were working on a more cost efective BB converted standard frame style turbo. Who knows how/if progress or still being considered.

#42

Evolved Member

Thread Starter

iTrader: (22)

Join Date: Nov 2003

Location: Northern KY near Cincy

Posts: 2,408

Likes: 0

Received 6 Likes

on

6 Posts

So what about intake pipes before the throttle body? Should they be as large as possible or smaller to keep pressure and volume up?

My HKS pipes taper out to the turbo, then taper into the FMIC then taper again at the merge to the upper pipe. Each taper is about 1/4 inch larger each time.

I've seen other pipe setups that have one taper out of the turbo and maintain consistent to the throttle body.

My HKS pipes taper out to the turbo, then taper into the FMIC then taper again at the merge to the upper pipe. Each taper is about 1/4 inch larger each time.

I've seen other pipe setups that have one taper out of the turbo and maintain consistent to the throttle body.

#43

Evolved Member

iTrader: (23)

This statement is an oxymoron. Pressure and volume are inversely proportional. You want consistant diameter with long bends to decrease head loss from piping. It is VERY miniscule when talking about these flows and these dimensions though. If you have ANY aftermarket piping you won't gain anything appreciable by changing without ditching the IC all together.

#45

Evolved Member

Thread Starter

iTrader: (22)

Join Date: Nov 2003

Location: Northern KY near Cincy

Posts: 2,408

Likes: 0

Received 6 Likes

on

6 Posts

This statement is an oxymoron. Pressure and volume are inversely proportional. You want consistant diameter with long bends to decrease head loss from piping. It is VERY miniscule when talking about these flows and these dimensions though. If you have ANY aftermarket piping you won't gain anything appreciable by changing without ditching the IC all together.

Then it comes down to fuel...

Then it comes down to fuel...