Attempting to tune my bucket of bolts..

#1

Newbie

Thread Starter

Attempting to tune my bucket of bolts..

Righteo, first of, the relevant specs:

1995 Lancer GSR (kind of like an Evo III for you americans)

1G block, 2G head.

9:1 CP pistons

Final compression ratio somewhere between 9:1 & 10:1

Kelford 1-TX268 cams (264 intake, 268 ex)

Mamba TD05H-18G (billet GTX style compressor/9 blade turbine)

750cc low impedance Siemens Deka injectors

Evo 6 fuel pump

Evo VII ECU & MAF

Now, I'm running 90550701 (tephra v7).

The car is currently running in open loop constantly because it seems like the brand new o2 sensor I put in with the new engine is dead (yay). So I forced it into O.L via the periphery.

Basically, I'm just trying to make the thing driveable. I spent this evening trying to get it to idle, by adjusting the ISC lookup table until it actually met the target idle.

It was idling at like 1400rpm and climbing until the ECU hit fuel cut (and just repeated doing that over and over), which as you can imagine was quite awkward at traffic lights.

So the idle with AC off seems sorted (or at least a band aid fix). Idle with AC on however, is stuffed. The rpm's dont climb to target, the ISC stops at about 70 steps, then after a few seconds drops down to the 30's, and the car basically stalls? (see here:

)

Any clues as to why the computer cant make the car idle with the AC on?

Ive set up the BISS screw via Evoscan so that activating the actuator makes hardly any difference to the idle (correct from what I have read).

Another issue.. I was trying to tune second gear, however my AFRMAP values are so far off the wideband readings that I've managed to hit the minimum AFRMAP value (7.4), and the car is still producing high 11 AFR's. So i thought I needed to rescale my MAF.

Started doing that via the guide on here, and what I find for some unknown reason, is that at idle the AFRMAP value is 17.1, however even just lightly touching the throttle moves it to 14.7.

I dont have any 17.1AFR values in my fuel map.. Ideas?

I began adjusting the MAF scaling but gave up because when I hold the engine at a particular RPM, the AFR plummets to about 11, and adjusting the MAF scaling doesnt seem to do anything (went from 165 to 50 @ 50Hz, and nothing seemed to actually change, so I think I'm just going to mess something up if I continue with that..)

Ive attached a couple of datalogs if anyones bored..

Where do I even begin with this damned car? Kind of sick of all its problems

1995 Lancer GSR (kind of like an Evo III for you americans)

1G block, 2G head.

9:1 CP pistons

Final compression ratio somewhere between 9:1 & 10:1

Kelford 1-TX268 cams (264 intake, 268 ex)

Mamba TD05H-18G (billet GTX style compressor/9 blade turbine)

750cc low impedance Siemens Deka injectors

Evo 6 fuel pump

Evo VII ECU & MAF

Now, I'm running 90550701 (tephra v7).

The car is currently running in open loop constantly because it seems like the brand new o2 sensor I put in with the new engine is dead (yay). So I forced it into O.L via the periphery.

Basically, I'm just trying to make the thing driveable. I spent this evening trying to get it to idle, by adjusting the ISC lookup table until it actually met the target idle.

It was idling at like 1400rpm and climbing until the ECU hit fuel cut (and just repeated doing that over and over), which as you can imagine was quite awkward at traffic lights.

So the idle with AC off seems sorted (or at least a band aid fix). Idle with AC on however, is stuffed. The rpm's dont climb to target, the ISC stops at about 70 steps, then after a few seconds drops down to the 30's, and the car basically stalls? (see here:

Any clues as to why the computer cant make the car idle with the AC on?

Ive set up the BISS screw via Evoscan so that activating the actuator makes hardly any difference to the idle (correct from what I have read).

Another issue.. I was trying to tune second gear, however my AFRMAP values are so far off the wideband readings that I've managed to hit the minimum AFRMAP value (7.4), and the car is still producing high 11 AFR's. So i thought I needed to rescale my MAF.

Started doing that via the guide on here, and what I find for some unknown reason, is that at idle the AFRMAP value is 17.1, however even just lightly touching the throttle moves it to 14.7.

I dont have any 17.1AFR values in my fuel map.. Ideas?

I began adjusting the MAF scaling but gave up because when I hold the engine at a particular RPM, the AFR plummets to about 11, and adjusting the MAF scaling doesnt seem to do anything (went from 165 to 50 @ 50Hz, and nothing seemed to actually change, so I think I'm just going to mess something up if I continue with that..)

Ive attached a couple of datalogs if anyones bored..

Where do I even begin with this damned car? Kind of sick of all its problems

#2

Evolved Member

You adjust injector scaling to give you more room in the fuel map. If you globally richen it up with scaling youll need to lean it out on the high octane map.

Maybe your open loop tables are causing the rich condition.

Maybe your open loop tables are causing the rich condition.

#3

Newbie

Thread Starter

My injector scaling is set to 720cc/min

Wouldn't leaning out the open loop fuel tables be a band aid fix for whatever the real issue is? Same with changing the injector scaling, if I tell it that it has 1000cc injectors then the IDC % is going to be hard to keep track of :/

Wouldn't leaning out the open loop fuel tables be a band aid fix for whatever the real issue is? Same with changing the injector scaling, if I tell it that it has 1000cc injectors then the IDC % is going to be hard to keep track of :/

#4

Account Disabled

You'd be better off by putting stock E7 injectors into it, running the E7 ECU with a stock map, then fixing it from there.

Then once you've fixed everything else, put the bigger injectors back in.

Why so high a CR?

Then once you've fixed everything else, put the bigger injectors back in.

Why so high a CR?

#5

Newbie

Thread Starter

Compression ratio is high because I wanted a really torquey midrange engine (which it has been)

#6

Evolving Member

Use an NEW Fuel Filter...could be clogged

Use an HEATED O2 Sensor ...the 7 ECU look for Heater....

Use an Walbro 255....stock ones will not flow enough

Check that the high low Fuel Pump relay is WORKING....Low power on Fuel pump will cause that

Try first with the Evo7 Stock injectors....no boost aka Wastegate pressure. (as low as possible

If it is sorted...then begin with Power Mapping

Check battery voltage...( Evo 7 has an output to switch the Alternator Off / lower drag

Connect Water lines to TB pipes...Evo 1-7 had High Idle bypass valve by Water temp. ( some older DSM / Evo 3 had reverse function of the idle servo )

Use the SAS function to adjust Bypass screw when fully WARMED up to 80 deg. Water temp ...

Take an unmodified 90550001 Rom First...in the tephra V7 are some bugs regarding the use in older Models due to Wire differences ( Clutch switch, Ayc / ACD torque reduction, TPS sensor Idle switch, Relays for Fans, Alternator , O2 sensor ....)

Do not suppress any Fault codes regarding the O2 sensor, doing so will have weird effects on Idle and Feedback values. Solve the errors by Wiring or Simulating, not by Periphery bits...

Do it step by step......

Use an HEATED O2 Sensor ...the 7 ECU look for Heater....

Use an Walbro 255....stock ones will not flow enough

Check that the high low Fuel Pump relay is WORKING....Low power on Fuel pump will cause that

Try first with the Evo7 Stock injectors....no boost aka Wastegate pressure. (as low as possible

If it is sorted...then begin with Power Mapping

Check battery voltage...( Evo 7 has an output to switch the Alternator Off / lower drag

Connect Water lines to TB pipes...Evo 1-7 had High Idle bypass valve by Water temp. ( some older DSM / Evo 3 had reverse function of the idle servo )

Use the SAS function to adjust Bypass screw when fully WARMED up to 80 deg. Water temp ...

Take an unmodified 90550001 Rom First...in the tephra V7 are some bugs regarding the use in older Models due to Wire differences ( Clutch switch, Ayc / ACD torque reduction, TPS sensor Idle switch, Relays for Fans, Alternator , O2 sensor ....)

Do not suppress any Fault codes regarding the O2 sensor, doing so will have weird effects on Idle and Feedback values. Solve the errors by Wiring or Simulating, not by Periphery bits...

Do it step by step......

#7

Newbie

Thread Starter

Use an NEW Fuel Filter...could be clogged

Use an HEATED O2 Sensor ...the 7 ECU look for Heater....

Use an Walbro 255....stock ones will not flow enough

Check that the high low Fuel Pump relay is WORKING....Low power on Fuel pump will cause that

Try first with the Evo7 Stock injectors....no boost aka Wastegate pressure. (as low as possible

If it is sorted...then begin with Power Mapping

Check battery voltage...( Evo 7 has an output to switch the Alternator Off / lower drag

Connect Water lines to TB pipes...Evo 1-7 had High Idle bypass valve by Water temp. ( some older DSM / Evo 3 had reverse function of the idle servo )

Use the SAS function to adjust Bypass screw when fully WARMED up to 80 deg. Water temp ...

Take an unmodified 90550001 Rom First...in the tephra V7 are some bugs regarding the use in older Models due to Wire differences ( Clutch switch, Ayc / ACD torque reduction, TPS sensor Idle switch, Relays for Fans, Alternator , O2 sensor ....)

Do not suppress any Fault codes regarding the O2 sensor, doing so will have weird effects on Idle and Feedback values. Solve the errors by Wiring or Simulating, not by Periphery bits...

Do it step by step......

Use an HEATED O2 Sensor ...the 7 ECU look for Heater....

Use an Walbro 255....stock ones will not flow enough

Check that the high low Fuel Pump relay is WORKING....Low power on Fuel pump will cause that

Try first with the Evo7 Stock injectors....no boost aka Wastegate pressure. (as low as possible

If it is sorted...then begin with Power Mapping

Check battery voltage...( Evo 7 has an output to switch the Alternator Off / lower drag

Connect Water lines to TB pipes...Evo 1-7 had High Idle bypass valve by Water temp. ( some older DSM / Evo 3 had reverse function of the idle servo )

Use the SAS function to adjust Bypass screw when fully WARMED up to 80 deg. Water temp ...

Take an unmodified 90550001 Rom First...in the tephra V7 are some bugs regarding the use in older Models due to Wire differences ( Clutch switch, Ayc / ACD torque reduction, TPS sensor Idle switch, Relays for Fans, Alternator , O2 sensor ....)

Do not suppress any Fault codes regarding the O2 sensor, doing so will have weird effects on Idle and Feedback values. Solve the errors by Wiring or Simulating, not by Periphery bits...

Do it step by step......

I did use the periphery bits to turn off the rear o2 and the front o2 heater circuit. Maybe I should simulate both with resistors then and see if that makes a difference.

I do have the water lines connected to the throttlebody, I used all factory parts so that should be all okay.

Ive used SAS setting to set the BISS screw, car idles nicely (as nice as you can with Kelfords!) with SAS mode enabled.

Car does not have a clutch switch, ACD, AYC, or alternator switching.

Does have the 4 pin TPS with the throttle closed switch inbuilt however. Fans all seems to work fine, pretty sure I got that stuff sorted when I did the pin swaps that enable me to run this ECU in this car.

Im going to get an Evo 3 throttlebody for it, the Galant VR4 one thats currently on there tends to stick quite often which is a pain.

Ill replace the o2 sensor and fix the heater/rear o2 CELs with resistors, then flash the standard ROM and see if the damned thing runs..

Trending Topics

#8

Account Disabled

If it won't run right on 560s then going to bigger ones will just make it all worse.

Higher compression, you need more octane otherwise you'll kill the engine with knock.

High IDCs (and hitting fuel cut) accompanied with lowish power mean that your fuel pressure is low when on boost.

Yet another example of faulty fuel pressure control which you'll find with a fuel pressure gauge.

#9

Newbie

Thread Starter

If it won't run right on 560s then going to bigger ones will just make it all worse.

Higher compression, you need more octane otherwise you'll kill the engine with knock.

High IDCs (and hitting fuel cut) accompanied with lowish power mean that your fuel pressure is low when on boost.

Yet another example of faulty fuel pressure control which you'll find with a fuel pressure gauge.

Higher compression, you need more octane otherwise you'll kill the engine with knock.

High IDCs (and hitting fuel cut) accompanied with lowish power mean that your fuel pressure is low when on boost.

Yet another example of faulty fuel pressure control which you'll find with a fuel pressure gauge.

A fuel rail with a pressure gauge might also be a wise investment no?

#10

Evolved Member

Sounds like your latency's are off. That lean condition at idle is what I'm referring too. Try increasing them slightly and see if that +17 afr gets better. Your IAC going from 70 counts down to 30 means it could be sticking, very common with IAC motors. After you get the idle afr closer try bringing up you injector scaling up one increment, that will richen up the map globally.

Sorry but I can't read any of the tables you posted. Once you get close you can start scaling the maf.

Sorry but I can't read any of the tables you posted. Once you get close you can start scaling the maf.

#11

Account Disabled

If you change the mapping when the fuel pressure is all wrong.......then when you fix the fuel pressure you'll need to go over the mapping again and fix all those things that you shouldn't have touched and screwed up.

Have you fitted a pressure gauge yet?

You should never change anything until you've taken measurements

You should never change anything until you've taken measurements

#12

Evolved Member

So your saying the afr map is changing from what you have it set too? Are logging target afr? Is that how your seeing this? Ok I see it now your target afr is 17. Not sure why that is unless it's using alternate map somehow. Your timing is going crazy that's one reason your idle is climbing around. Jack up the timing more in the 500-1000 rpm to big of a jump from 500-1500 also you can limit the amount of timing in the idle timing comp table.

I seriously think your latencys are off a lot

That target afr is weird tho

I seriously think your latencys are off a lot

That target afr is weird tho

Last edited by 2winscroll; Sep 6, 2017 at 02:20 PM.

#13

Account Disabled

Latencies are always off when the fuel pressure is off.

That's because a change in fuel pressure makes a change to the opening times.

More pressure = slower to open.

Less pressure = quicker to open.

Less pressure = smaller usable pulsewidth = better idle.

No point in random changing of parts either without measuring things first.

Otherwise you'll end up wasting lots of $$$$$ on un needed parts, then end up with a big pile of leftovers where you don't know what's good from bad.

That's because a change in fuel pressure makes a change to the opening times.

More pressure = slower to open.

Less pressure = quicker to open.

Less pressure = smaller usable pulsewidth = better idle.

No point in random changing of parts either without measuring things first.

Otherwise you'll end up wasting lots of $$$$$ on un needed parts, then end up with a big pile of leftovers where you don't know what's good from bad.

Last edited by RightSaid fred; Sep 7, 2017 at 02:15 AM.

#14

Newbie

Thread Starter

If there were issues wth fuel pressure I doubt the thing would scream at 8000rpm on boost the way it does without any issues

I've ordered a replacement pump because it was on the to-do-list anyway. Deatschwerks DW300 should do the trick

The idle instability seems to be caused by the AFRMAP Value fluctuating between 14.7 (stable idle), then shooting up to 17.1 (unstable idle) for no apparent reason. The fuel maps are all set to 14.7 in the idle areas, and the timing isn't set to any unusual values.

I've ordered a replacement pump because it was on the to-do-list anyway. Deatschwerks DW300 should do the trick

The idle instability seems to be caused by the AFRMAP Value fluctuating between 14.7 (stable idle), then shooting up to 17.1 (unstable idle) for no apparent reason. The fuel maps are all set to 14.7 in the idle areas, and the timing isn't set to any unusual values.

#15

Evolved Member

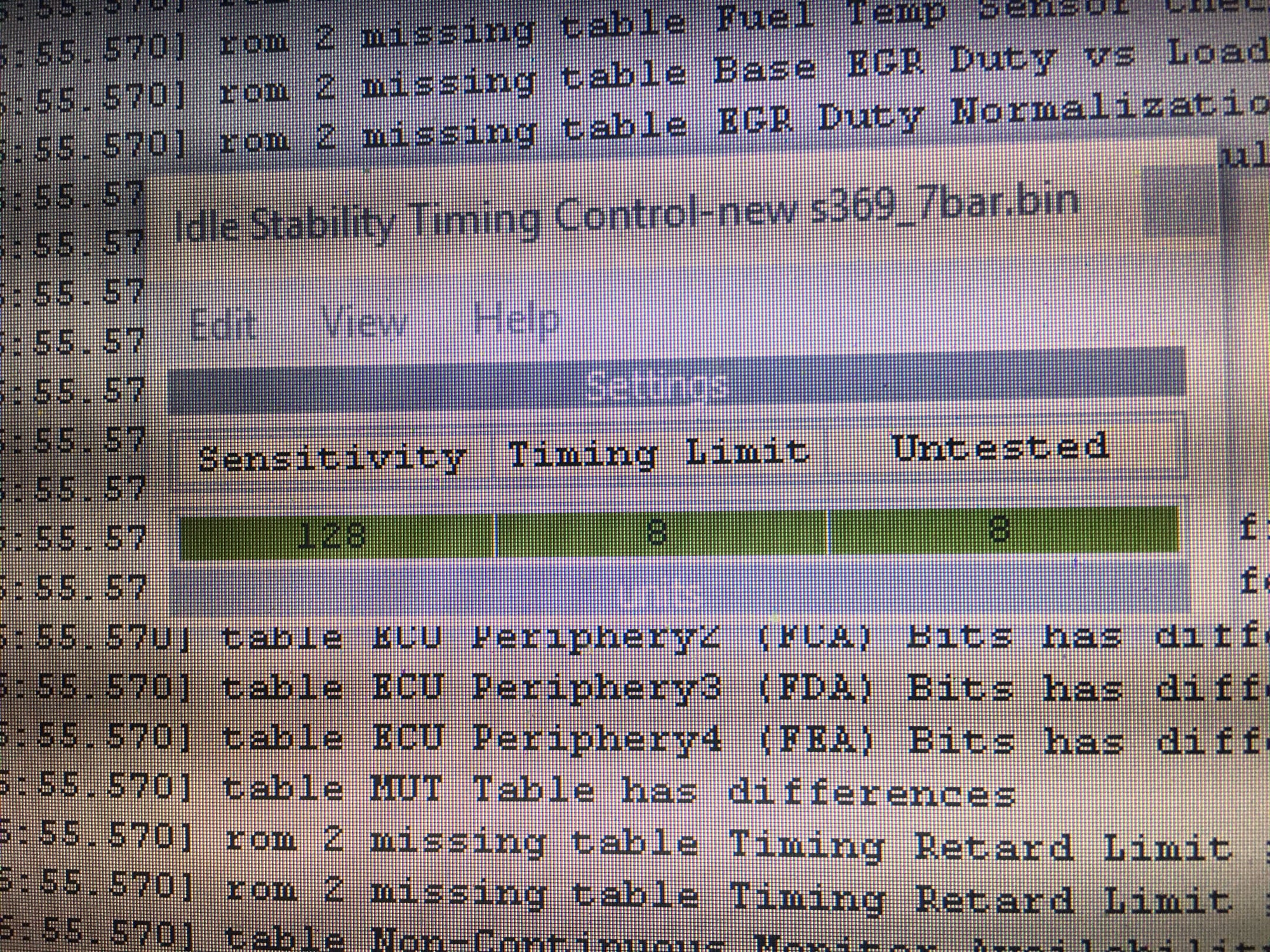

This is the table I'm referring too. It adjusts timing control the idle. You can turn it down to around 4 degrees to see if it's a timing problem. If your 1000 rpm cell is a huge difference from the 1500 cell, then it can hunt the idle.

As far as the afr table goes, I would try and rescale both X and Y axis to a lower value and see what happens. post your XML file for your load table too.