for anyone that has crankcase pressure issues

#1472

EvoM Guru

iTrader: (1)

No, we're talking about cam timing, not ignition timing.

#1474

Evolved Member

iTrader: (41)

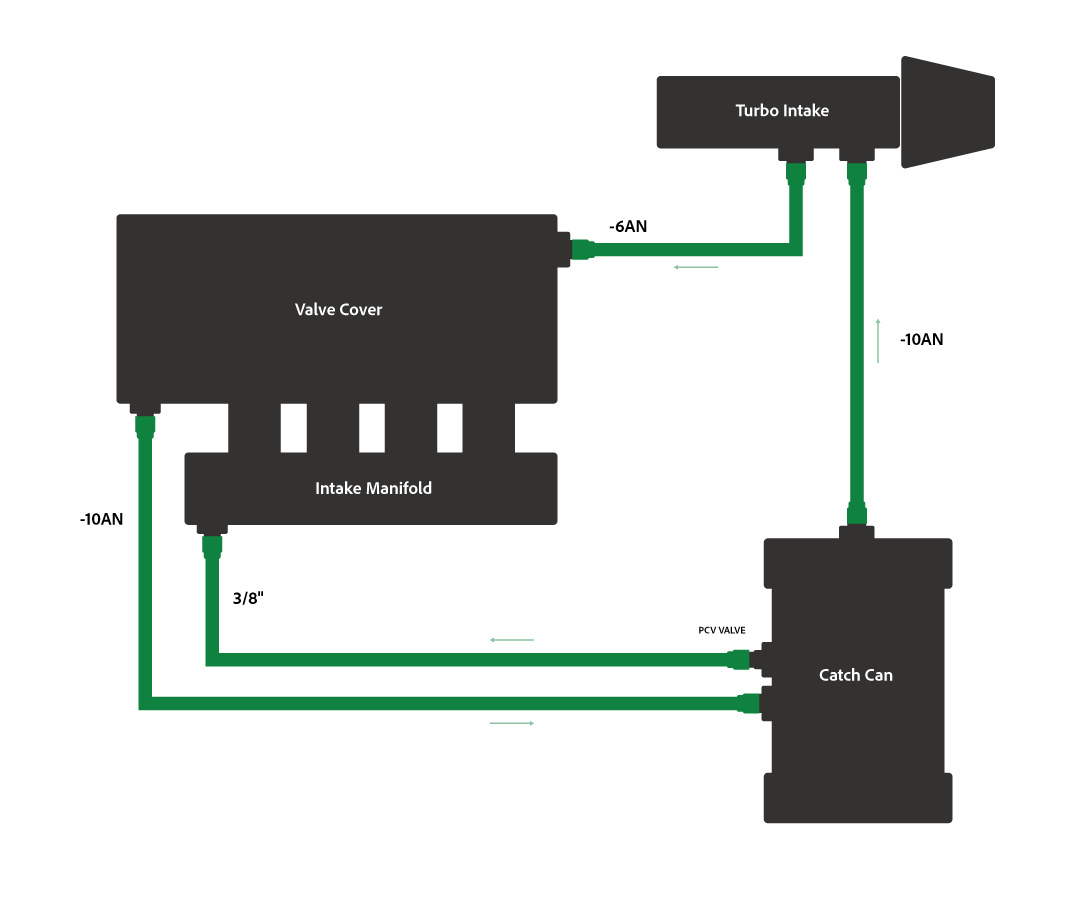

I'm looking for some thoughts on the crankcase pressure/catch can issues I'm dealing with right now. My biggest problem right now is that whenever I hookup the line with the check valve running to the intake manifold, the car wants to idle around 2000-2500 rpms and won't go any lower, even after it warms up. If I block off the port at the intake manifold and then just run the line on the back of the VC to the can it idles fine, but I'm pretty sure it's pushing oil past the turbo seals because I get a little bit of smoke at idle. Anybody have any idea on what could be causing the high idle issue? I'm also on E85 FWIW.

In fact, the system is pulling so much vacuum at idle now that it's hard to get the oil cap off when the car is running

In fact, the system is pulling so much vacuum at idle now that it's hard to get the oil cap off when the car is running

What's the solution? Run the STM sealed catch can setup exactly the way they have it diagrammed with BOTH check valves. The reason I was having issues before was that I was only using a check valve in the line running to the IM. I bought this setup used and was missing the check valve that goes between the can and the intake to the turbo. Now that I have both check valves in, it pulls plenty of vacuum at idle to keep the turbo happy.

One other thing I want to mention though is that if you are going to run the STM sealed setup, DO NOT run a line from your dipstick to the can. After I got the 2nd check valve installed, the system was pulling so much vacuum that it was actually siphoning oil out of the pan.

Hopefully, that helps some of you!

P.S. No broken pistons here

Just needed a properly working catch can system.

Just needed a properly working catch can system.

The following users liked this post:

ronaldo9 (Sep 28, 2017)

#1475

EvoM Guru

iTrader: (1)

#1476

What's the solution? Run the STM sealed catch can setup exactly the way they have it diagrammed with BOTH check valves. The reason I was having issues before was that I was only using a check valve in the line running to the IM. I bought this setup used and was missing the check valve that goes between the can and the intake to the turbo. Now that I have both check valves in, it pulls plenty of vacuum at idle to keep the turbo happy.

#1477

Evolving Member

iTrader: (1)

What's the solution? Run the STM sealed catch can setup exactly the way they have it diagrammed with BOTH check valves. The reason I was having issues before was that I was only using a check valve in the line running to the IM. I bought this setup used and was missing the check valve that goes between the can and the intake to the turbo. Now that I have both check valves in, it pulls plenty of vacuum at idle to keep the turbo happy.

Just a question, I don't know the STM setup. It use Intake manifold vacuum to scavenge the engine? And when the engine is under boost how it works?

#1479

EvoM Guru

iTrader: (50)

Just wanted to update everyone on where I'm at with the issues I was having. I'm happy to report that I'm no longer experiencing crankcase pressure issues

In fact, the system is pulling so much vacuum at idle now that it's hard to get the oil cap off when the car is running

In fact, the system is pulling so much vacuum at idle now that it's hard to get the oil cap off when the car is running

What's the solution? Run the STM sealed catch can setup exactly the way they have it diagrammed with BOTH check valves. The reason I was having issues before was that I was only using a check valve in the line running to the IM. I bought this setup used and was missing the check valve that goes between the can and the intake to the turbo. Now that I have both check valves in, it pulls plenty of vacuum at idle to keep the turbo happy.

...

In fact, the system is pulling so much vacuum at idle now that it's hard to get the oil cap off when the car is running

In fact, the system is pulling so much vacuum at idle now that it's hard to get the oil cap off when the car is running

What's the solution? Run the STM sealed catch can setup exactly the way they have it diagrammed with BOTH check valves. The reason I was having issues before was that I was only using a check valve in the line running to the IM. I bought this setup used and was missing the check valve that goes between the can and the intake to the turbo. Now that I have both check valves in, it pulls plenty of vacuum at idle to keep the turbo happy.

...

#1480

EvoM Guru

iTrader: (1)

At idle, once the crankcase reaches zero psi, that check valve closes so that the intake manifold does simply draw air through it. With it closed, the intake manifold can draw a vacuum on the crankcase.

#1481

EvoM Guru

iTrader: (50)

The check valve going to the intake pipe only allows air flow to the intake pipe. Therefore, the flow rate into the intake manifold during vacuum conditions in the intake manifold is limited to the rate of blow-by. With the factory PCV system where there is no check valve in the line to the intake pipe, the air flow into the intake manifold can be much higher because outside air is pulled through the valve cover and will take water and fuel vapor with it, so the ability to pull water and fuel vapor out of the crankcase is much better.

#1482

EvoM Guru

iTrader: (1)

Water and fuel vapor in the crankcase are mostly only there due to blow by though. Vehicles with dry sumps run a sealed crank case which is in vacuum thanks to the dry sump pump. I don't think getting every bit of water/fuel vapor out by circulating air through the valve cover is a big concern.

#1483

EvoM Guru

iTrader: (50)

Water and fuel vapor in the crankcase are mostly only there due to blow by though. Vehicles with dry sumps run a sealed crank case which is in vacuum thanks to the dry sump pump. I don't think getting every bit of water/fuel vapor out by circulating air through the valve cover is a big concern.

#1484

EvoM Guru

iTrader: (1)

I could do that. But my car sits a lot and may not be a good representation for it.

#1485

Former Sponsor

iTrader: (31)

The only thing you need is to drill the passenger side of the valve cover out to 5/8" drill and tap, add fitting and it will cure all the crankcase pressure issues.

If it doesn't, then there's something else going on. I've never seen that mod we do not fix crankcase pressure issues on any cars, and I've done the mod now to around 80 valve covers to date.

I would still put a 'catch' can in between the pcv and intake mani to eliminate the possibility of oil entering the intake tract or just eliminating the pcv altogether, but I didn't even do that on my last setup which was pretty serious considering with 36psi it went 148 in 1/4 with poor driving and the plenum was dry when i took the setup apart to sell the shortblock.

Most of your large evo shops do what I said above for all their large in house builds and their personal cars.

If you do not want to drill or tap the cover then the sealed catch can using the intake as vacuum is definitely the next best thing. Vented cans wont outperform the sealed when the sealed is setup correctly, but if you drill the holes in the cover large and run to a vented can that will definitely outperform the sealed system but can only be used on SD setups.

If it doesn't, then there's something else going on. I've never seen that mod we do not fix crankcase pressure issues on any cars, and I've done the mod now to around 80 valve covers to date.

I would still put a 'catch' can in between the pcv and intake mani to eliminate the possibility of oil entering the intake tract or just eliminating the pcv altogether, but I didn't even do that on my last setup which was pretty serious considering with 36psi it went 148 in 1/4 with poor driving and the plenum was dry when i took the setup apart to sell the shortblock.

Most of your large evo shops do what I said above for all their large in house builds and their personal cars.

If you do not want to drill or tap the cover then the sealed catch can using the intake as vacuum is definitely the next best thing. Vented cans wont outperform the sealed when the sealed is setup correctly, but if you drill the holes in the cover large and run to a vented can that will definitely outperform the sealed system but can only be used on SD setups.