Voltage oscillation/drop during WOT pulls…… V swings between 13.8 to 12.3V

#21

Update: I just went through an engine build, so I couldn’t resist swapping the alternator to a new unit. Unfortunatly it wasn’t oem, however, it was from a local auto parts store that a friend recommended as he had used it and seen good results. Link below

http://www.oreillyauto.com/site/c/de...ord=alternator

Currently the behavior as follows;

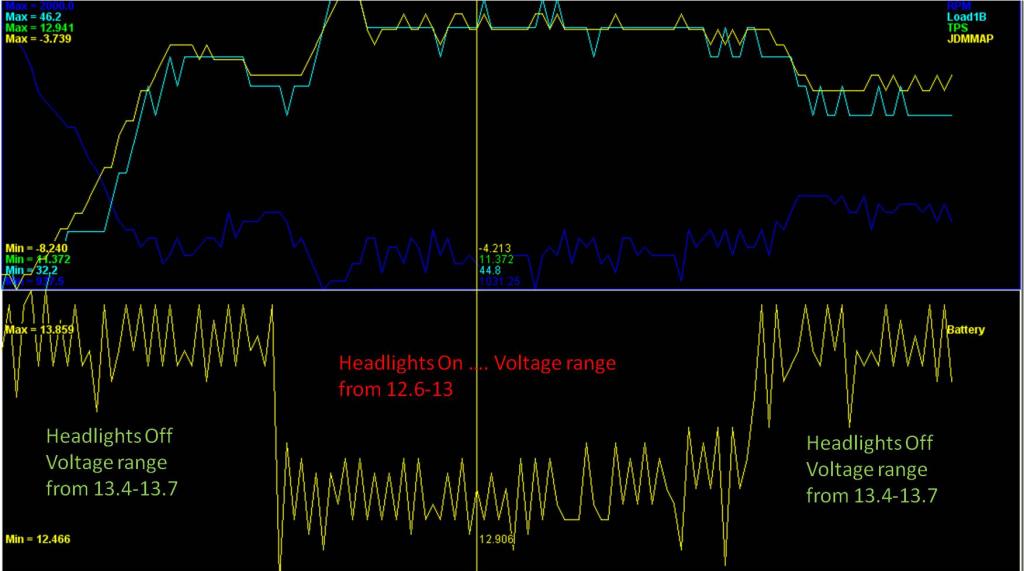

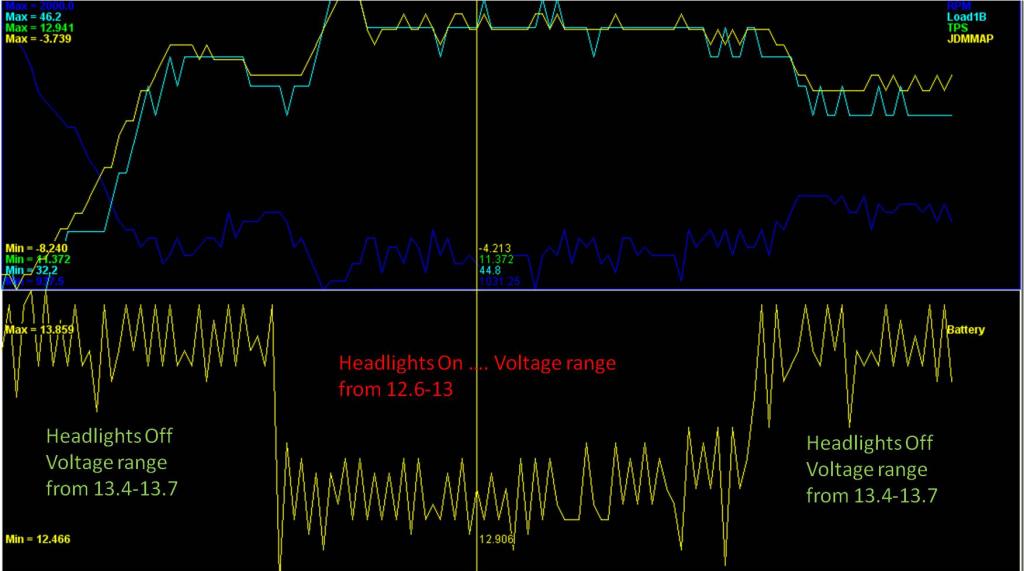

Idle with headlights OFF is ~13.4-13.7 V

Idle with headlights ON is ~12.4-13.0 V

So you can imagine at night while coming to a stop it becomes tricky to keep the engine alive.

Things I have done so far;

1) Tried multiple alternators 1 used oem and the latest is brand new from a local store.

2) Added 3 additional grounds to the engine….2 on thermostat housing and 1 on one of the exhaust manifold studs.

3) Added a direct 10 gauge wire from the positive terminal of the battery to the alternator to rule out a bad harness.

4) Replaced the mini battery as well, but it doesn’t get driven much so I usually leave it on the charger prior to drives.

The car is fully built now on speed density with a double pumper.

I can’t think of anything else to try to improve this aside from maybe adding an additional ground directly to the alternator. It is worth mentioning that I had to delete the ground that typical goes on the intake manifold due to running an AMS F1.

Screen shot below shows the difference in the engine voltage via evoscan with and without the headlights during a warm idle.

Any other recommendations?

Thanks

http://www.oreillyauto.com/site/c/de...ord=alternator

Currently the behavior as follows;

Idle with headlights OFF is ~13.4-13.7 V

Idle with headlights ON is ~12.4-13.0 V

So you can imagine at night while coming to a stop it becomes tricky to keep the engine alive.

Things I have done so far;

1) Tried multiple alternators 1 used oem and the latest is brand new from a local store.

2) Added 3 additional grounds to the engine….2 on thermostat housing and 1 on one of the exhaust manifold studs.

3) Added a direct 10 gauge wire from the positive terminal of the battery to the alternator to rule out a bad harness.

4) Replaced the mini battery as well, but it doesn’t get driven much so I usually leave it on the charger prior to drives.

The car is fully built now on speed density with a double pumper.

I can’t think of anything else to try to improve this aside from maybe adding an additional ground directly to the alternator. It is worth mentioning that I had to delete the ground that typical goes on the intake manifold due to running an AMS F1.

Screen shot below shows the difference in the engine voltage via evoscan with and without the headlights during a warm idle.

Any other recommendations?

Thanks

#22

Update: I just went through an engine build, so I couldn’t resist swapping the alternator to a new unit. Unfortunatly it wasn’t oem, however, it was from a local auto parts store that a friend recommended as he had used it and seen good results. Link below

http://www.oreillyauto.com/site/c/de...ord=alternator

Currently the behavior as follows;

Idle with headlights OFF is ~13.4-13.7 V

Idle with headlights ON is ~12.4-13.0 V

So you can imagine at night while coming to a stop it becomes tricky to keep the engine alive.

Things I have done so far;

1) Tried multiple alternators 1 used oem and the latest is brand new from a local store.

2) Added 3 additional grounds to the engine….2 on thermostat housing and 1 on one of the exhaust manifold studs.

3) Added a direct 10 gauge wire from the positive terminal of the battery to the alternator to rule out a bad harness.

4) Replaced the mini battery as well, but it doesn’t get driven much so I usually leave it on the charger prior to drives.

The car is fully built now on speed density with a double pumper.

I can’t think of anything else to try to improve this aside from maybe adding an additional ground directly to the alternator. It is worth mentioning that I had to delete the ground that typical goes on the intake manifold due to running an AMS F1.

Screen shot below shows the difference in the engine voltage via evoscan with and without the headlights during a warm idle.

Any other recommendations?

Thanks

http://www.oreillyauto.com/site/c/de...ord=alternator

Currently the behavior as follows;

Idle with headlights OFF is ~13.4-13.7 V

Idle with headlights ON is ~12.4-13.0 V

So you can imagine at night while coming to a stop it becomes tricky to keep the engine alive.

Things I have done so far;

1) Tried multiple alternators 1 used oem and the latest is brand new from a local store.

2) Added 3 additional grounds to the engine….2 on thermostat housing and 1 on one of the exhaust manifold studs.

3) Added a direct 10 gauge wire from the positive terminal of the battery to the alternator to rule out a bad harness.

4) Replaced the mini battery as well, but it doesn’t get driven much so I usually leave it on the charger prior to drives.

The car is fully built now on speed density with a double pumper.

I can’t think of anything else to try to improve this aside from maybe adding an additional ground directly to the alternator. It is worth mentioning that I had to delete the ground that typical goes on the intake manifold due to running an AMS F1.

Screen shot below shows the difference in the engine voltage via evoscan with and without the headlights during a warm idle.

Any other recommendations?

Thanks

Did you solve your problem? My Battery Voltage in Evoscan even drops to 10.8 volts at WOT. Similar to your problem, i can't reach a consistent AFR and every pull is different

. I put up a voltage meter to the Alternator directly and monitored it under WOT and it keeps up to 14+ volts always. Not sure what the problem is!. Already put up many ground wires and i don't think it's ground issue.

. I put up a voltage meter to the Alternator directly and monitored it under WOT and it keeps up to 14+ volts always. Not sure what the problem is!. Already put up many ground wires and i don't think it's ground issue. The battery voltage that is being read by Evoscan is : what is being read by the ECU or whats supplied to the ODB2 connector?

#24

Account Disabled

It's not a problem, it's perfectly normal behaviour.

That's why it's so important that you don't fit a fuel pump that outflows the FPR because then the fuel pressure (along with the AFR) goes up and down with the voltage.

That's what makes it stall, not the low voltage. An engine will run on less than 12V if it's tuned right.

The output of an alternator is proportional to RPM and no alternator can give full output at idle.

Injector dead time is affected by voltage but it's also affected by fuel pressure and fuel pressure is affected by voltage when the FPR is being outflowed.

That's why it's so important that you don't fit a fuel pump that outflows the FPR because then the fuel pressure (along with the AFR) goes up and down with the voltage.

That's what makes it stall, not the low voltage. An engine will run on less than 12V if it's tuned right.

The output of an alternator is proportional to RPM and no alternator can give full output at idle.

Injector dead time is affected by voltage but it's also affected by fuel pressure and fuel pressure is affected by voltage when the FPR is being outflowed.

Last edited by RightSaid fred; Jun 15, 2017 at 11:15 PM.

#25

Evolved Member

It's not a problem, it's perfectly normal behaviour.

That's why it's so important that you don't fit a fuel pump that outflows the FPR because then the fuel pressure (along with the AFR) goes up and down with the voltage.

That's what makes it stall, not the low voltage. An engine will run on less than 12V if it's tuned right.

The output of an alternator is proportional to RPM and no alternator can give full output at idle.

Injector dead time is affected by voltage but it's also affected by fuel pressure and fuel pressure is affected by voltage when the FPR is being outflowed.

That's why it's so important that you don't fit a fuel pump that outflows the FPR because then the fuel pressure (along with the AFR) goes up and down with the voltage.

That's what makes it stall, not the low voltage. An engine will run on less than 12V if it's tuned right.

The output of an alternator is proportional to RPM and no alternator can give full output at idle.

Injector dead time is affected by voltage but it's also affected by fuel pressure and fuel pressure is affected by voltage when the FPR is being outflowed.

You mean this happens when the fuel pump is drawing more current ?

#26

It's not a problem, it's perfectly normal behaviour.

That's why it's so important that you don't fit a fuel pump that outflows the FPR because then the fuel pressure (along with the AFR) goes up and down with the voltage.

That's what makes it stall, not the low voltage. An engine will run on less than 12V if it's tuned right.

The output of an alternator is proportional to RPM and no alternator can give full output at idle.

Injector dead time is affected by voltage but it's also affected by fuel pressure and fuel pressure is affected by voltage when the FPR is being outflowed.

That's why it's so important that you don't fit a fuel pump that outflows the FPR because then the fuel pressure (along with the AFR) goes up and down with the voltage.

That's what makes it stall, not the low voltage. An engine will run on less than 12V if it's tuned right.

The output of an alternator is proportional to RPM and no alternator can give full output at idle.

Injector dead time is affected by voltage but it's also affected by fuel pressure and fuel pressure is affected by voltage when the FPR is being outflowed.

#27

Account Disabled

When you fit a bigger than stock fuel pump and you don't replace the FPR, you'll outflow the FPR.

Your fuel pressure will be 7 to 8 PSI too high at idle with a walbro 255.

When the pump is outflowing the FPR, the pressure is no longer being regulated and the pressure is dependent on the voltage.

When the electrical load at idle or low load changes (fans and lights on and off) the fuel pressure will also change.

When the fuel pressure changes, the AFR changes too.

More fuel pressure makes the injectors slower to open (more dead time).

Less fuel pressure makes the injectors open quicker.

More voltage makes the injectors open quicker.

Less voltage makes the injectors slower to open (more dead time).

The voltage variation isn't a problem with a car that's tuned properly because it's got voltage compensation tables.

But there's no input to the ECU for variations in fuel pressure.

Fuel pressure has to be stable at all times, as in the pressure across the injector which is the difference between gauge pressure and manifold pressure.

A bigger pump draws more current so puts more load on the electrical system at low RPM when the alternator is making the least power.

If it's an AFR problem AND the pump has been changed to a bigger one..........the idle pressure is always too high.

Unless the FPR has also been upgraded and not downgraded.

A fuel pressure gauge gives the answer every time.

What I haven't yet mentioned is that if you keep on forcing too much fuel through an OEM FPR for too long, eventually the FPR will fail and it starts running at a lower pressure under load.

So instead of reading 3 bar(43ish PSI) base pressure it will drop to maybe only 30 PSI..................but it all takes time. The spring loses it load.

Your fuel pressure will be 7 to 8 PSI too high at idle with a walbro 255.

When the pump is outflowing the FPR, the pressure is no longer being regulated and the pressure is dependent on the voltage.

When the electrical load at idle or low load changes (fans and lights on and off) the fuel pressure will also change.

When the fuel pressure changes, the AFR changes too.

More fuel pressure makes the injectors slower to open (more dead time).

Less fuel pressure makes the injectors open quicker.

More voltage makes the injectors open quicker.

Less voltage makes the injectors slower to open (more dead time).

The voltage variation isn't a problem with a car that's tuned properly because it's got voltage compensation tables.

But there's no input to the ECU for variations in fuel pressure.

Fuel pressure has to be stable at all times, as in the pressure across the injector which is the difference between gauge pressure and manifold pressure.

A bigger pump draws more current so puts more load on the electrical system at low RPM when the alternator is making the least power.

Unless the FPR has also been upgraded and not downgraded.

A fuel pressure gauge gives the answer every time.

What I haven't yet mentioned is that if you keep on forcing too much fuel through an OEM FPR for too long, eventually the FPR will fail and it starts running at a lower pressure under load.

So instead of reading 3 bar(43ish PSI) base pressure it will drop to maybe only 30 PSI..................but it all takes time. The spring loses it load.

Last edited by RightSaid fred; Jun 16, 2017 at 01:43 AM.

#28

Evolved Member

How will you determine which is dropping first. Fuel pressure or voltage. I have seen voltage drop on idle and cruise from 12-12.9 volts and same on decel.