Risk with running engines with 1 or 2 low compression cylinders

The following users liked this post:

RightSaid fred (Mar 20, 2018)

#32

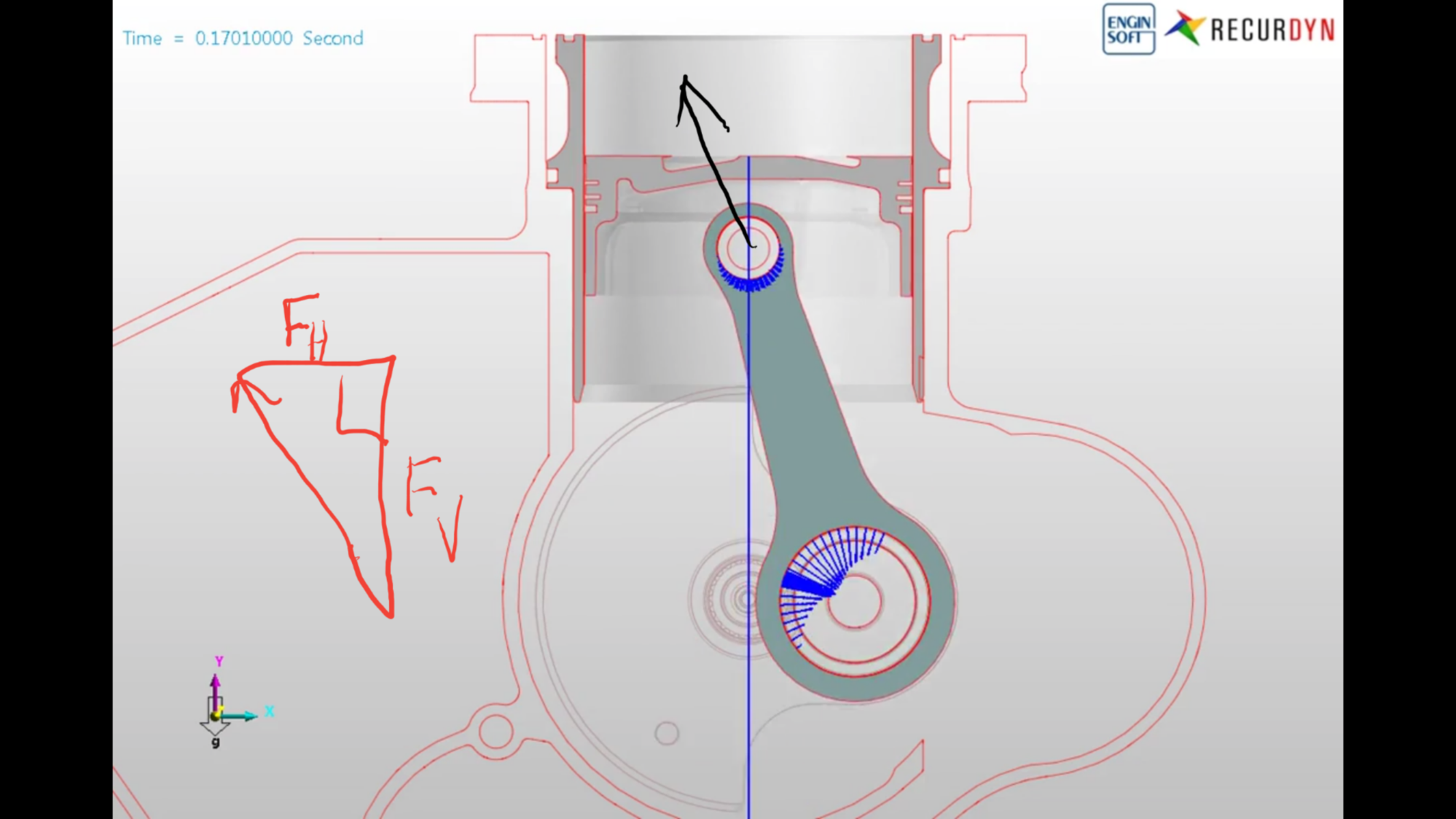

Pins will push pistons at different angles as rods rotate crank. How does pistons stay vertical inside cylinders? Equal and opposite reactions.

Last edited by 2006EvoIXer; Mar 20, 2018 at 07:56 AM.

#35

Evolving Member

iTrader: (1)

I'm not disagreeing that the main purpose of rings are to seal combustion chamber and keep oil out of it. I was thinking about the forces.

Pins will push pistons at different angles as rods rotate crank. How does pistons stay vertical inside cylinders? Equal and opposite reactions.

Pins will push pistons at different angles as rods rotate crank. How does pistons stay vertical inside cylinders? Equal and opposite reactions.

The following users liked this post:

2006EvoIXer (Mar 20, 2018)

#36

EvoM Guru

iTrader: (12)

Just make sure you tell them what to check. Building your own engine is not bad, it's just time consuming and you have to be very meticulous. If you can get your hands on a decent set of micrometers, magnetic base indicators, and a dial bore gauge, you have a solid start. You're going to want to clean and blueprint your block first, then take it to a machine shop where they can perform the machine work according to YOUR specs. For example, honing each cylinder to your specified numbers so that your PTW is equal. Each piston is slightly different so each bore must have a different amount removed from it in the honing process . These days I always encourage people to also pay close attention to the radial contact pressure that the bearings impose upon the main and rod bores (bearing crush) because that is one of the primary items keeping you from spinning bearings. Bearings need a surgically clean surface to etch themselves in properly.

The following users liked this post:

2006EvoIXer (Apr 2, 2018)

#37

Thanks Pal215. I didn't know that the pistons aren't exactly the same!

I think it was Razorlab that said his block ran another +60k miles since he put his back (that looked as worn as mine does). I'll see how my bottom end does with a refreshed head. If it ends up bad, you'll be getting PMs from me. You have been warned!

Hopefully, the top part of my cylinders are in good shape to keep making power. The wear is at bottom, so it's not in critical area.

I think it was Razorlab that said his block ran another +60k miles since he put his back (that looked as worn as mine does). I'll see how my bottom end does with a refreshed head. If it ends up bad, you'll be getting PMs from me. You have been warned!

Hopefully, the top part of my cylinders are in good shape to keep making power. The wear is at bottom, so it's not in critical area.

#38

EvoM Guru

iTrader: (12)

Thanks Pal215. I didn't know that the pistons aren't exactly the same!

I think it was Razorlab that said his block ran another +60k miles since he put his back (that looked as worn as mine does). I'll see how my bottom end does with a refreshed head. If it ends up bad, you'll be getting PMs from me. You have been warned!

Hopefully, the top part of my cylinders are in good shape to keep making power. The wear is at bottom, so it's not in critical area.

I think it was Razorlab that said his block ran another +60k miles since he put his back (that looked as worn as mine does). I'll see how my bottom end does with a refreshed head. If it ends up bad, you'll be getting PMs from me. You have been warned!

Hopefully, the top part of my cylinders are in good shape to keep making power. The wear is at bottom, so it's not in critical area.

No problem, I just went through the process so it's still fresh in my head. I'll answer what I can, but letsgetthisdone knows more.

The following users liked this post:

2006EvoIXer (Apr 3, 2018)

#39

I'm set on Carrillo Pro H with Carriage bolts but have no idea on which pistons. 85.5mm is the likely bore.

Last edited by 2006EvoIXer; Apr 3, 2018 at 08:37 AM.

#40

EvoM Guru

iTrader: (12)

Since it's freah in your head, what challenges did you run into other than piston set not being exactly the same? (I would have thought they would be in this day and age!)

I'm set on Carrillo Pro H with Carriage bolts but have no idea on which pistons. 85.5mm is the likely bore.

I'm set on Carrillo Pro H with Carriage bolts but have no idea on which pistons. 85.5mm is the likely bore.

1. Take your time using the piston ring filer, you'll only be grinding two rings per piston (1st and 2nd compression rings). The second compression ring is thicker and won't fit in the first compression rings ring-land. They are different materials and will grind at a different rate. Pay attention to this or else you will accidentally grind away too much material, making your ring gaps too big.

2. Use a digital caliper to check your micrometers (not just the calibration cylinders/blocks included in the kit), use micrometers to check your dial bore gauge, then use your digital caliper to check your dial bore gauge. All these tools need to agree with each other or else write down the offset of your least accurate tool (which should be your digital caliper) and use it as a sanity check for your calculations later.

3. Write down all of your measurements. Use coffee filters, denatured alcohol, and compressed air to clean and sanitize. Do not use mineral spirits.

4. When it comes time to pack the oil pump with grease or vaseline, there are 4 bolts and a single philips screw that's very easy to strip holding the oil pump together. Use an impact driver to loosen that stupid screw if it feels like it's going to strip. The bolts are easy enough.

5. DO NOT use a conventional piston compressor tool. Invest in a tapered piston ring compressor because if you use the regular wind up piston compressor, it will move your piston rings around and you can't be sure that they are clocked properly once you install the pistons in the block.

6. If your thumb accidentally touches a bearing bore surface (rod or main), do not install a bearing half until you clean it again with alcohol and blow it off with compressed air.

7. You can use an air compressor or a can of electronics duster, but don't get too close to the surface you are blowing on, moister can come out of both tools.

8. When measuring rod and main bearing clearance, take the smallest measurement of your bores(bearings installed and studs/bolts torqued to spec) and subtract from it the largest measurement of your journals.

9. Only bore and hone your block using a torque plate. A torque plate will simulate the forces imposed on the short block when the cylinder head is bolted into place. This way you can be sure that when the cylinder head is torqued to the block, the cylinders stay round.

10. If you are using a piston that uses an oil support rail, place the dimple on the bottom and let it catch on the gap of the wrist pin, otherwise it will rotate and clock your oil rings incorrectly, causing you to burn oil like crazy.

11. If you screw up and mix up the rod caps, you can relocate their original rod by examining the crosshatch inside the rod bore using a bright light and a magnifying glass. You need to install the rod cap on each rod first and then inspect to see if the cross hatch lines complete each other when they meet at the dividing line. There should be a seamless feel between the rod cap and rod side edges where they meet.

Building your own 4g63 is a very rewarding experience, especially with time and money you save. There's no mystery or special secret.

Last edited by Pal215; Apr 5, 2018 at 04:05 PM.

The following 2 users liked this post by Pal215:

2006EvoIXer (Apr 3, 2018),

butte (Apr 4, 2018)

Thread

Thread Starter

Forum

Replies

Last Post

EVO KiiD

Evo Engine / Turbo / Drivetrain

24

Sep 4, 2016 10:06 PM

graphitegrey9

Evo Engine / Turbo / Drivetrain

17

Feb 3, 2012 10:14 PM

alexso15

General Engine Management / Tuning Forum

25

May 22, 2010 06:32 PM