EVO X MR SST Tech Info

#1

EVO X MR SST Tech Info

The dual clutch Getrag TC-SST (Sportronic Shift Transmission) 6-speed, found in the EVO X, is a very compact and complex unit. We service them- please click HERE

To find a unit like this in a car that is not a $100k+ exotic is very cool and us tech geeks love these things! For Mitsubishi to include the option to have them in the X shows how performance oriented the car really is. Unfortunately, the SST unit is so complicated that very few people know how to repair them. Your average Mitsu tech, who is trained to work on an econo-box, won't have a clue and will just blindly replace the unit without ever cracking it open. On top of that, Getrag is notorious for pushing full replacement of the unit when it has a problem, and will not sell parts. This is becoming a serious problem for X owners now that their warranties are expiring. I can see why Getrag would do this. Due to the complexity of the unit, as a manufacturer, you don't want your average tech digging into them and try to fix them. In most cases, the unit may not function properly after the inexperienced tech performs repairs and quality is compromised. This is my guess as to how a company can keep quality up and control the repairs to their product to insure proper operation.

Luckily, we can repair these units and also upgrade them! We have access to all parts for repairs (sorry, we can't sell them yet. We can only use them for repairs here) and have a very solid experience with complex units like these due to our willingness to learn how they work and our engineering mentality.

The dealer usually wants to replace the unit for $12k, but we were able to repair the units pictured below for a small fraction of that price! These were the perfect units to take pictures of so we can show how it works, the weak links, and what can be done to increase reliability.

CLUTCH ASSEMBLY

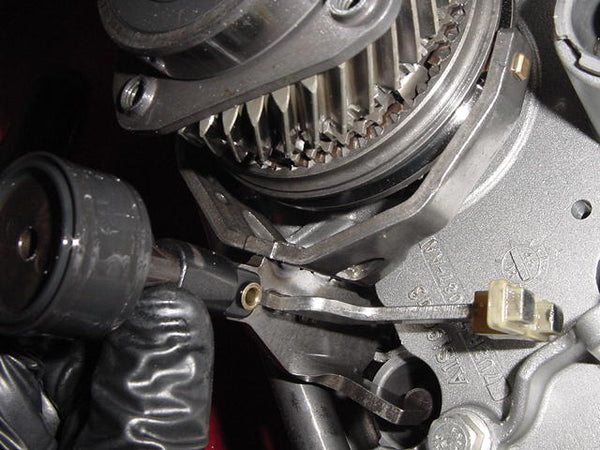

This picture shows the clutch pack assembly removed from the trans along with all other parts associated with the clutch system.

The clutches create friction and clamp down on the disks via hydraulic pressure. The more pressure applied, the less slip and more clamp load

The clutch system is actually very simple in how it works. The system has 4 oil lines from the valve body which control pressure to the disks for clamping load and cooling.

The image below is of the center shaft which feeds the clutches their oil. Note there are 4 oil channels. The two in the center (2 and 3) are there to distribute oil to the clutches for cooling. The two outer channels (1 and 4) are there to supply pressure to the disks for clamp loading. All 4 of these oil passages are fed from the valve body assembly.

Pictured here is the outer housing which the seal sits into. This housing sits on top of the assembly pictured above:

The seal does 3 things. It seals around the outside in the outer housing assembly to keep pressure in, it will apply force to the clutch packs once hydraulic pressure is pushed through, and it seals against a second seal, which sits below it and prevents fluid from escaping at the clutch pack area. So you essentially have 2 large seals which need to be perfect in order to hold pressure, and on top of all of that, they need to survive the heat generated by the disks. Both clutch packs have the same two seals and they work the same way. Oil port #1 feeds pressure to one set of seals and clutches, and port #4 feeds pressure to the other set of seals and clutches.

Picture of seals below. Left=top, right=bottom of seals:

If you have a trans which is slipping, it could be a seal failure. We can replace these seals with new high temp units to prevent the failure from happening again if you wish to upgrade them.

Under these seals are the clutch packs. There are 4 friction disks for each clutch assembly. There can be up to 5 of them depending on the performance package you want.

We can install replacement clutch disks depending on your goals. There are types which have a more friction surface area and a way to fit 5 total disks into the assembly. Contact us if you need help in this area also.

The springs you see in the center of the hub are there to hold the clutch pack apart, when hydraulic pressure is taken away, to assure a full release from that clutch assembly. If the disks drag while the trans is trying to select a gear, it could ruin the synchros.

OVER-HEATING PROBLEMS

Heat created by the clutch disks is also a known problem for the SST. One major complaint you hear about with dual clutch transmissions is how harsh they shift in city driving. A show called 'Gop Tear' has its hosts always complaining about how harsh they shift in slow city traffic. I personally don't understand this. If you buy a race car, how can you expect it to shift perfectly in hot city traffic? Due to this, it's my guess that the engineers for this SST trans tried to design this unit to shift very smoothly, so as to not have owners complain about the harshness of the shifting in the city. They did a great job! I was shocked when I felt the EVO SST for the first time. It felt like a total slush-box and didn't have the same quick engagement you feel through other vehicles with dual clutch systems. When in 'normal' mode, this trans could be mistaken for a real automatic with a torque converter. It doesn't feel like a dual clutch system at all! This is great for the person that wants an MR to feel like an econo-box, but this also causes many other problems.

The unfortunate side affect to smooth engagement of the clutches is it creates a lot of heat. When the clutches are in the 'friction zone' (the area where they are creating friction) they generate heat, and when you generate heat, you have wear and the unit is more prone to clutch and seal failure. It's like a driver in a manually shifted car riding the clutch everywhere they go. You will quickly burn up the clutch and kill it.

Overheating with the SST is a common annoyance, and a car which is supposed to be designed to run at the track will be forced to stop by an over-heating transmission in short time. The common fix for this is to install a high-end oil cooler, and pump system, so as to keep the fluid cool. This seems to work for most people, but I believe the over-heating issues is not caused by lack of cooling via the factory cooler, but too much friction, and slipping, through the disks. When at the track, the SST will not completely stop the heavy slipping of the disks when you change gears. Doing this repeatedly will eventually create so much heat that the factory cooling system can't keep up and the system shuts down to protect itself.

I believe the solution for the over-heating issue is to make the clutches switch and engage faster. The quicker the engagement, the less friction, which means less heat generated. Unfortunately, the faster the engagement, the harsher the shift around the city.

I can't imagine that the Getrag engineers were so stupid as to design a trans which over-heats so quickly. What I believe happened was they designed a unit which was supposed to engage quicker, which is why the cooling system for the unit is so small. When Mitsubishi noticed the complaints people had with the harsher shifting units in the exotics, the unit was already done and the engineers responsible for the programming of the unit had to make changes for smoother engagement. I believe there may have been a lack of communication between the electrical and the mechanical engineers during the development of this unit. The engineers which programmed the system to shift smoothly didn't take into account the fact that smooth shifting creates friction, which will over-heat the unit. I believe the over-heating issue is a programming problem in the ECU and can easily be repaired without the need for expensive oil cooler fixes.

I am trying to learn all I can about changing the way the trans shifts via reprogramming the system, but I am a bit weak in this area. If anyone out there has found a way to modify the shifting of this trans via the factory ECU, so it shifts from one clutch to the other more quickly, please let me know and I would be willing to possibly ship some units your way to try. I believe if the clutches are in the 'friction zone' for as little as possible that the clutches will live longer, seals will not fail, and the trans will not over-heat.

I do not want to change the quickness of the SST shifts by modifying the valve body. I believe doing that will make it shift harshly all of the time and the car will not be pleasant to drive at slow speeds. If we can modify the program, then we can keep the smooth city driving shifts and modify the high load/high RPM shifts so the customer can have the best of both Worlds.

AREAS WHERE OTHERS NEVER DARE TOUCH

Picture below of both case halves open and sitting next to each other. Note you have a small gear cluster on one side and another cluster on the other side:

Note how clean the cases are after we washed, ultrasonic cleaned, and pulse flushed them below!

HYDRAULIC SHIFT FORK ACTUATION via piston

The SST uses small pistons, on each end of the shift fork, to move the fork UP and DOWN to engage the gear. How it works is simple. The valve body transfers hydraulic pressure to the back side of a piston and it simply pushes the shift fork into gear. The synchros, sliders, forks, etc are all very much the same as a manual trans, only difference is the system uses pistons to push the fork where it needs to go. Magnets on the fork tell the ECU sensors where it is positioned, so it knows the gear is engaged, or in neutral.

Picture below of a piston:

VALVE BODY ASSEMBLY

Picture of the valve body. Note the towering black plastic parts. Those have sensors on the ends of them which extend inside the trans, so they can sit next to the fork magnets in order to sense the fork position. The valve body also has a series of solenoids which are the most commonly misdiagnosed part in the trans.

GEAR CLUSTERS

The SST has 2 sets of gear clusters. One set has its own input shaft, output shaft, parking pawl, 2nd, 4th and 6th gears with synchros and forks. In this picture, you can see a second hollow shaft over the 2, 4, 6th input shaft. This is the input shaft for 1st, 3rd, 5th and reverse:

Here is another picture of the cluster with the 1st, 3rd, 5th and reverse input shaft removed:

Yet another view of the 2nd, 4th and 6th gear cluster. Starting from the bottom you have the input and output gears, parking pawl, 2nd gear, 4th gear, and 6th gear.

Picture of the 1st, 3rd, 5th and reverse gear cluster. Note that I am holding the hollow shaft which we looked at in the previous picture:

Hollow input shaft installed. You can see the tach wheel on the back end of the shaft, so the ECU knows what RPM it is turning. Note the center diff has both sets of output gears attached to it. The only thing separating the two clusters from each other are the two clutches:

Another view of the cluster removed from the case. Starting from the bottom you have 1st gear, reverse, input and output, then above you have 3rd and 5th ending at the top:

Another view of the same cluster from the other side. With all forks attached:

To have the clusters in 1-3-5-R odd, and 2-4-6 even, gears makes sense as you want one cluster to be free while the other is in use. This way the clutch only needs to switch when engaging the next gear. No need to wait for the next gear to shift, it's already engaged and ready to go!

The gear sets in this trans look to be very strong and well engineered. It looks like they can take the abuse from harsher clutch engagement and smooth shifting is not needed. The smooth clutch engagement is only for driver comfort. Once we find a way to allow the clutches to engage faster, as I believe they were designed to, we will add it to our build list on the website.

Last edited by Jacks Transmissions; Jan 4, 2013 at 11:16 AM.

#2

SERVICING YOUR SST

There are several things we can do to these units, here at Jacks Transmissions. We can repair ANY problem with the unit. If you are local, we very highly recommend that you bring us the whole vehicle for testing and NOT the trans only.

For our out-of-State customers, if you want to ship us your trans, we would be more than happy to upgrade and/or repair it. Due to the complexity of the unit, we will need as much information as possible from you BEFORE you remove the trans. We will need to know what it is doing, what error codes are popping up and what kind of work you would like performed. Some problems are harder to diagnose than others. We very much need every detail of the problem before you pull your trans.

For example: The TCU could be pulling up error codes for a #1 clutch issue, 1st gear fork engagement issue, and solenoid issue. Many people believe that when they see many codes pop up from a failure, that it is automatically the TCU which is the problem. You would not believe how many hundreds of emails we get of people asking for a TCU as they believe it's bad due to the long list of codes it is producing. In the example above, the codes produced were due to a clutch thrust washer failure and the TCU was fine. You need to understand the thinking behind the TCU before making assumptions as to what the problem is. To the TCU, what it was trying to do was apply pressure to the #1 clutch so it could engage 1st gear. With the clutch unable to move due to the thrust failure, the TCU concluded that there was a solenoid issue, as it could not detect clutch movement. This was not correct. It also thought there was a fork issue as it could not engage 1st gear. Well, think about it. If you get into a manual car while it's running and not depress the clutch pedal while trying to shift it into 1st gear, would you be able to engage 1st gear? No, you wouldn't, but the TCU is doing the same thing while trying to shift into 1st, but is unable to due to the clutch problem. What needs to be done for proper analysis of an issue like this is to put the pieces together as to why all of these codes are popping up and what it is related to.

We have ways of testing the unit in-house. We can test the clutches, pistons, synchros, forks, sensors and solenoids. We can't test everything on the bench, though, and in rare cases the only way to know for sure that the problem is cured is to have the unit installed in the vehicle.

We can also perform many upgrades to the unit. We can add a larger oil pan for more oil capacity, inline filter, large cooler and pump, many magnets inside the unit to prevent metal build-up on the sensor fork magnets, high temp clutch seals, and a range of high HP clutch packs to fit your goals. The best way to know what you need is to EMAIL us and tell us what the problem is, and what your goals are with the car. We can then give you an accurate and detailed quote for a trans, which will live and work the way it should.

We have the best equipment and techs in the business to properly service your SST. Just our cleaning equipment alone is something most shops dream of and is very important to assure a clean and quality repair to your SST. Example of one step of the cleaning process involved with your SST here below:

Rest assured that your SST will be repaired and/or upgraded with the highest level of care, and quality, to assure a long and trouble free service life from your trans! Experience counts, and we know these units intimately. Many of the gear cluster pictures above were of a unit in which we had to perform a full rebuild to. Note how clean the clusters were. Every part of that trans was torn down, inspected, and cleaned to perfection. Have the same great service performed to your SST!

Thanks for visiting!! Phone contact 719-243-5305 or feel free to email at sales@jackstransmissions.com

There are several things we can do to these units, here at Jacks Transmissions. We can repair ANY problem with the unit. If you are local, we very highly recommend that you bring us the whole vehicle for testing and NOT the trans only.

For our out-of-State customers, if you want to ship us your trans, we would be more than happy to upgrade and/or repair it. Due to the complexity of the unit, we will need as much information as possible from you BEFORE you remove the trans. We will need to know what it is doing, what error codes are popping up and what kind of work you would like performed. Some problems are harder to diagnose than others. We very much need every detail of the problem before you pull your trans.

For example: The TCU could be pulling up error codes for a #1 clutch issue, 1st gear fork engagement issue, and solenoid issue. Many people believe that when they see many codes pop up from a failure, that it is automatically the TCU which is the problem. You would not believe how many hundreds of emails we get of people asking for a TCU as they believe it's bad due to the long list of codes it is producing. In the example above, the codes produced were due to a clutch thrust washer failure and the TCU was fine. You need to understand the thinking behind the TCU before making assumptions as to what the problem is. To the TCU, what it was trying to do was apply pressure to the #1 clutch so it could engage 1st gear. With the clutch unable to move due to the thrust failure, the TCU concluded that there was a solenoid issue, as it could not detect clutch movement. This was not correct. It also thought there was a fork issue as it could not engage 1st gear. Well, think about it. If you get into a manual car while it's running and not depress the clutch pedal while trying to shift it into 1st gear, would you be able to engage 1st gear? No, you wouldn't, but the TCU is doing the same thing while trying to shift into 1st, but is unable to due to the clutch problem. What needs to be done for proper analysis of an issue like this is to put the pieces together as to why all of these codes are popping up and what it is related to.

We have ways of testing the unit in-house. We can test the clutches, pistons, synchros, forks, sensors and solenoids. We can't test everything on the bench, though, and in rare cases the only way to know for sure that the problem is cured is to have the unit installed in the vehicle.

We can also perform many upgrades to the unit. We can add a larger oil pan for more oil capacity, inline filter, large cooler and pump, many magnets inside the unit to prevent metal build-up on the sensor fork magnets, high temp clutch seals, and a range of high HP clutch packs to fit your goals. The best way to know what you need is to EMAIL us and tell us what the problem is, and what your goals are with the car. We can then give you an accurate and detailed quote for a trans, which will live and work the way it should.

We have the best equipment and techs in the business to properly service your SST. Just our cleaning equipment alone is something most shops dream of and is very important to assure a clean and quality repair to your SST. Example of one step of the cleaning process involved with your SST here below:

Rest assured that your SST will be repaired and/or upgraded with the highest level of care, and quality, to assure a long and trouble free service life from your trans! Experience counts, and we know these units intimately. Many of the gear cluster pictures above were of a unit in which we had to perform a full rebuild to. Note how clean the clusters were. Every part of that trans was torn down, inspected, and cleaned to perfection. Have the same great service performed to your SST!

Thanks for visiting!! Phone contact 719-243-5305 or feel free to email at sales@jackstransmissions.com

Last edited by Jacks Transmissions; Jan 4, 2013 at 10:58 AM.

Thread

Thread Starter

Forum

Replies

Last Post

hollywood_X

Mitsubishi TC-SST Discussion

13

Oct 9, 2012 01:49 PM