Building a new factory longblock

#1

Building a new factory longblock

Building a new factory longblock...and then installing it in my little tiny garage

**I'm still new around here, so some of this is kind of a newbie/intro post**

Hey all,

I'm building a new factory longblock for my 2003 Evo 8. I'm going to share at least part of that here. This thread is going to be more about documenting and sharing the information in case it is helpful for others in the future. I have been lurking here since 2007 and have benefited greatly from your collective EvoM experience so I hope to return the favor.

I will likely be making updates in smaller chunks to hopefully make the task less daunting. This is not intended to be a How To.

First, some background, and what led me to this current project.

My best friend bought an Evo new in 2003. He is a good dude and less of a nerd than I and let me get pretty involved with the build, and gave me a lot of seat time. Reading SCC back in the day, I already was in love with the Evo but when my buddy got this car I went completely nuts. In 2004 that car got an ATP GT3071R kit and AEM series 1 etc, and in 2006/07 got a 2.3 and E85. It was a monster. Very fun to drive, but I moved away and my friend's waning interest led to him selling the car in 2010. Here's a pic of me as an awkward teenager in 2001, and a pic of my buddy's Evo in about 2008.

And here's a pic from a SoCal Evo meet back in the day at XS Engineering...August 04. I did not take this pic, but I remember it well. My first time experiencing an atmosphere dump EWG. Standing 20 feet from the dyno I about shat my pants. It was love. Haha.

Unfortunately I was young and broke and it would be 10 years before I could afford my own Evo. In the meantime I had several other cars...finally got into the 4G63T game myself in 2007 when I purchased a Galant VR-4. Here's a glamour shot (lol) of that turd.

In 2013 I could finally "afford" to purchase my first Evo. The car was owned by an older gentleman, and was stock down to the head unit with the exception of a K&N SRI. It had 70k miles and I would be the 3rd owner, so I immediately made arrangements to go pick it up from NorCal. Here's a pic I took right when I got home from that 8 hour drive back to Socal, at about 3 am.

Learning from experience with my friend's Evo, my own vehicles and also working in the performance/tuning industry both selling and manufacturing parts for the last decade has cultivated a respect and appreciation for the development and engineering process that go into building a vehicle, particularly a performance vehicle, so I tend to be more careful these days with my approach. All that to say that I haven't gone too crazy with my own Evo...the overall "balance" of these cars is pretty darn good from the factory and I only wish to add to the car and not compromise it in any respect, as much as possible.

Coming from a whole slew of other Japanese cars, the Evo is the most reliable vehicle I have ever owned. These are incredibly robust vehicles if maintained and modified carefully. I've done 11 HPDEs with this car and it was never phased. I work for the HMSA part time and our home track is Laguna Seca, so lots of 800 mile road trips up there. This car has taken me everywhere and never, ever let me down.

The only reason I stopped tracking it was because I built an S2000 DE car instead. Here's that car:

Which leads us to now....building a new engine for my Evo

What finally took this engine down was a stuck thermostat (as far as I can tell- I will tear the engine down a little later). I believe the contributing factors here were that I had all but stopped driving the car at this point, and I had so much faith in the car that I was a bit oblivious and not paying as much attention as I had previously.

Here's the short-er story if you are interested

I went back to school and commuted in the car daily. I hated putting the miles on it, so I bought a commuter and in November 2017 reduced the Evo's use to 1-2x per month at best. It just sat in the garage for the most part while I was busy with school. I busted the car out in July 2018 to go to MOD here in SoCal, and the thermostat stuck shut on the freeway. I didn't catch it. I did look down at the gauge when I got off the freeway and saw 235* (in July) and have no idea how long the car sustained "too hot" ECT.

I went home and changed the T Stat, and the car seemed OK. A few months and maybe 200 miles later, I was looking the car over and noticed that the coolant level in the overflow had dropped a bit. I kept an eye on it but this became a pattern. I noticed a loss of several oz. of coolant every couple hundred miles. The car still ran great. No overheating, no coolant in the oil that I could see, or vice versa. The car appeared to be making full power and I could not find any external leaks.

Occasionally I had trouble starting the car. Since it was approaching winter and I was running E85, I wasn't too worried about the difficult cold starts. But I had a feeling something was up. I compression tested the car and it was not only very close across all 4 cylinders but very high numbers. Warm not hot engine, at sea level, and I was cranking until the needle stopped jumping. 182, 185, 185, 190. In retrospect I wish I had done it with the engine a bit hotter, and maybe only 5 cranks per cylinder. In any event, I was more concerned about finding a low cylinder than outright numbers. Also, the car did not, and still does not, push any coolant into the overflow. If it had ever done that, it would have made this whole diagnostics process more of a no-brainer. I had RRE torture test the car on the dyno. We ran 5 gals of E85 through it at a very high ramp rate to really load the F out of the engine, trying to get it to start puking coolant or something. Nope. Not a drop. We actually disconnected the overflow and ran a piece of tubing from the rad up onto the windshield to make it really easy to spot. Not a ****ing drop.

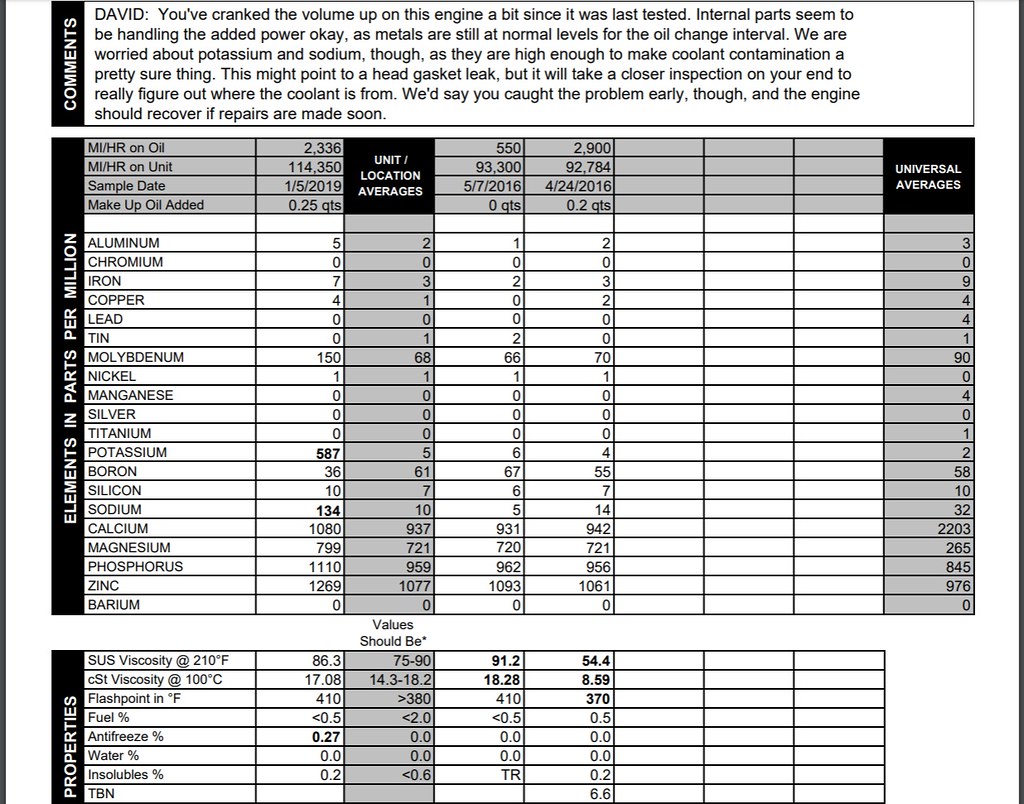

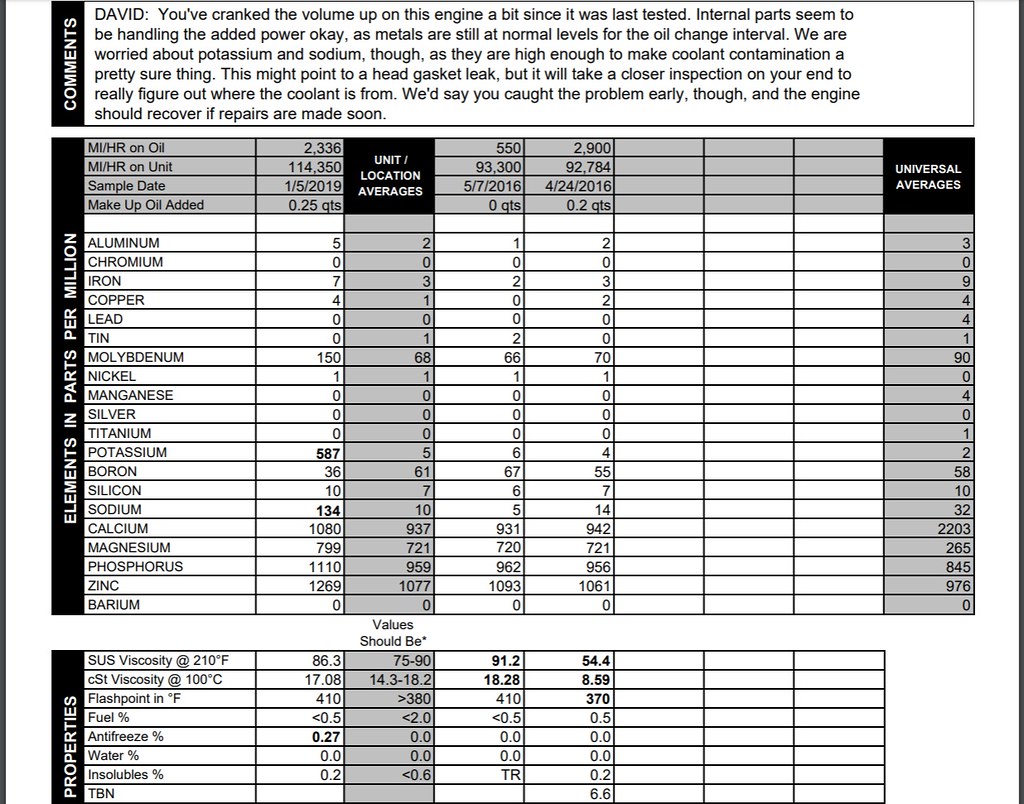

I also sent a sample off to Blackstone for analysis. This is when I knew that I did in fact have a problem.

(for anyone wondering, those other two earlier UOAs were on the same oil- M1 15w50, and I was looking at its endurance during track use)

Also tested the coolant for traces of combusion gas. Nothing.

It became obvious that the only way to figure out what was really going on was to get into the motor. So, I decided that i'd build a new factory long block, and then tear down the original engine for a proper inspection/ diagnostics.

**I'm still new around here, so some of this is kind of a newbie/intro post**

Hey all,

I'm building a new factory longblock for my 2003 Evo 8. I'm going to share at least part of that here. This thread is going to be more about documenting and sharing the information in case it is helpful for others in the future. I have been lurking here since 2007 and have benefited greatly from your collective EvoM experience so I hope to return the favor.

I will likely be making updates in smaller chunks to hopefully make the task less daunting. This is not intended to be a How To.

First, some background, and what led me to this current project.

My best friend bought an Evo new in 2003. He is a good dude and less of a nerd than I and let me get pretty involved with the build, and gave me a lot of seat time. Reading SCC back in the day, I already was in love with the Evo but when my buddy got this car I went completely nuts. In 2004 that car got an ATP GT3071R kit and AEM series 1 etc, and in 2006/07 got a 2.3 and E85. It was a monster. Very fun to drive, but I moved away and my friend's waning interest led to him selling the car in 2010. Here's a pic of me as an awkward teenager in 2001, and a pic of my buddy's Evo in about 2008.

And here's a pic from a SoCal Evo meet back in the day at XS Engineering...August 04. I did not take this pic, but I remember it well. My first time experiencing an atmosphere dump EWG. Standing 20 feet from the dyno I about shat my pants. It was love. Haha.

Unfortunately I was young and broke and it would be 10 years before I could afford my own Evo. In the meantime I had several other cars...finally got into the 4G63T game myself in 2007 when I purchased a Galant VR-4. Here's a glamour shot (lol) of that turd.

In 2013 I could finally "afford" to purchase my first Evo. The car was owned by an older gentleman, and was stock down to the head unit with the exception of a K&N SRI. It had 70k miles and I would be the 3rd owner, so I immediately made arrangements to go pick it up from NorCal. Here's a pic I took right when I got home from that 8 hour drive back to Socal, at about 3 am.

Learning from experience with my friend's Evo, my own vehicles and also working in the performance/tuning industry both selling and manufacturing parts for the last decade has cultivated a respect and appreciation for the development and engineering process that go into building a vehicle, particularly a performance vehicle, so I tend to be more careful these days with my approach. All that to say that I haven't gone too crazy with my own Evo...the overall "balance" of these cars is pretty darn good from the factory and I only wish to add to the car and not compromise it in any respect, as much as possible.

Coming from a whole slew of other Japanese cars, the Evo is the most reliable vehicle I have ever owned. These are incredibly robust vehicles if maintained and modified carefully. I've done 11 HPDEs with this car and it was never phased. I work for the HMSA part time and our home track is Laguna Seca, so lots of 800 mile road trips up there. This car has taken me everywhere and never, ever let me down.

The only reason I stopped tracking it was because I built an S2000 DE car instead. Here's that car:

Which leads us to now....building a new engine for my Evo

What finally took this engine down was a stuck thermostat (as far as I can tell- I will tear the engine down a little later). I believe the contributing factors here were that I had all but stopped driving the car at this point, and I had so much faith in the car that I was a bit oblivious and not paying as much attention as I had previously.

Here's the short-er story if you are interested

I went back to school and commuted in the car daily. I hated putting the miles on it, so I bought a commuter and in November 2017 reduced the Evo's use to 1-2x per month at best. It just sat in the garage for the most part while I was busy with school. I busted the car out in July 2018 to go to MOD here in SoCal, and the thermostat stuck shut on the freeway. I didn't catch it. I did look down at the gauge when I got off the freeway and saw 235* (in July) and have no idea how long the car sustained "too hot" ECT.

I went home and changed the T Stat, and the car seemed OK. A few months and maybe 200 miles later, I was looking the car over and noticed that the coolant level in the overflow had dropped a bit. I kept an eye on it but this became a pattern. I noticed a loss of several oz. of coolant every couple hundred miles. The car still ran great. No overheating, no coolant in the oil that I could see, or vice versa. The car appeared to be making full power and I could not find any external leaks.

Occasionally I had trouble starting the car. Since it was approaching winter and I was running E85, I wasn't too worried about the difficult cold starts. But I had a feeling something was up. I compression tested the car and it was not only very close across all 4 cylinders but very high numbers. Warm not hot engine, at sea level, and I was cranking until the needle stopped jumping. 182, 185, 185, 190. In retrospect I wish I had done it with the engine a bit hotter, and maybe only 5 cranks per cylinder. In any event, I was more concerned about finding a low cylinder than outright numbers. Also, the car did not, and still does not, push any coolant into the overflow. If it had ever done that, it would have made this whole diagnostics process more of a no-brainer. I had RRE torture test the car on the dyno. We ran 5 gals of E85 through it at a very high ramp rate to really load the F out of the engine, trying to get it to start puking coolant or something. Nope. Not a drop. We actually disconnected the overflow and ran a piece of tubing from the rad up onto the windshield to make it really easy to spot. Not a ****ing drop.

I also sent a sample off to Blackstone for analysis. This is when I knew that I did in fact have a problem.

(for anyone wondering, those other two earlier UOAs were on the same oil- M1 15w50, and I was looking at its endurance during track use)

Also tested the coolant for traces of combusion gas. Nothing.

It became obvious that the only way to figure out what was really going on was to get into the motor. So, I decided that i'd build a new factory long block, and then tear down the original engine for a proper inspection/ diagnostics.

Last edited by Apex Hunter; Jun 18, 2019 at 04:40 PM.

The following users liked this post:

city (Jun 16, 2019)

#2

P.S.

I've made a little more progress than what's indicated here, but that post took f'ing FOREVER and it was time to get out to the garage. So, more to come.

If I have questions, I'll be sure to make them obvious or make very short posts.

My main goal here is to share info....takes work tracking some of this info down, beyond just getting really familiar with the factory service manual. Will consolidate as much as possible.

My main concern is that I have a very small workspace, and it's not nearly as clean as i'd like.

I've made a little more progress than what's indicated here, but that post took f'ing FOREVER and it was time to get out to the garage. So, more to come.

If I have questions, I'll be sure to make them obvious or make very short posts.

My main goal here is to share info....takes work tracking some of this info down, beyond just getting really familiar with the factory service manual. Will consolidate as much as possible.

My main concern is that I have a very small workspace, and it's not nearly as clean as i'd like.

#3

Step 1 - Clean

A clean workspace is pretty crucial for engine work. I'd hate for a little piece of grit to get into one of those bearing clearances somewhere in the new engine, and screw up this already outrageously expensive endeavor. So the first thing I wanted to work on was making my garage a cleaner place in general, from high to low. Being that I don't have a lot of space, I store a good amount of our stuff up high, so I wanted to plan ahead a bit and make sure there wasn't anything myself or my fiancee would need from up in the rafters anytime soon, and also make sure to address any problem areas up there. Next I just moved everything out of the garage, and swept and vacuumed.

Also good to think about where to store things during the project, as it would take place over several weeks. I had an extra set of wheels in the left corner next to the workbench. My better half allowed me to keep these on our patio for the time being. I moved the air compressor under the workbench, this way I could use the spot under the workbench of the far right to store the engine/trans combo. My plan is to pull the existing engine/trans out the top, put them on a creeper, and roll them under the bench. The area on the left side of the bench will just fit my engine stand.

Sorry for the blurry second photo...I only include it to give an idea of the layout. I think this is the cleanest my garage has ever been. I have done a lot of garage sweeping over the years, but never vacuumed my garage, haha.

A clean workspace is pretty crucial for engine work. I'd hate for a little piece of grit to get into one of those bearing clearances somewhere in the new engine, and screw up this already outrageously expensive endeavor. So the first thing I wanted to work on was making my garage a cleaner place in general, from high to low. Being that I don't have a lot of space, I store a good amount of our stuff up high, so I wanted to plan ahead a bit and make sure there wasn't anything myself or my fiancee would need from up in the rafters anytime soon, and also make sure to address any problem areas up there. Next I just moved everything out of the garage, and swept and vacuumed.

Also good to think about where to store things during the project, as it would take place over several weeks. I had an extra set of wheels in the left corner next to the workbench. My better half allowed me to keep these on our patio for the time being. I moved the air compressor under the workbench, this way I could use the spot under the workbench of the far right to store the engine/trans combo. My plan is to pull the existing engine/trans out the top, put them on a creeper, and roll them under the bench. The area on the left side of the bench will just fit my engine stand.

Sorry for the blurry second photo...I only include it to give an idea of the layout. I think this is the cleanest my garage has ever been. I have done a lot of garage sweeping over the years, but never vacuumed my garage, haha.

#4

FCK! That's about where I was at last night when I called it quits. Somehow, when I first opened up the shortblock package, I thought I saw the rear main seal/housing already installed on there. Yeah I was wrong about that. So got that ordered up this morning.

Last night after work, finally got the engine on the stand. Took a couple more pictures to better illustrate the setup.

The old engine/trans combo will come out of the car, and then temporarily live on that creeper, in the corner under the bench.

The new engine currently resides on the stand. (btw- my aging phone needs to be put out of its misery. It's challenging getting this thing to stay in focus. Apologies for the blurry photos, I will work on this :/

Once the engine was on the stand, it was time for my favorite thing, MORE CLEANING. This is a constant.

The new shortblock did not come very well sealed. It was in a plastic bag, which had been opened and then shoddily re-taped together at some point. But when you have to wait 5 weeks for them to get the damn thing over here from JP, and you're working with a deadline, you have to weigh that.

I took a few engines classes about 10 years ago. One thing that stuck with me was that ATF and clean, white cotton works great for cleaning the cylinder bores. The ATF really helps the cotton pick up any crud and provides a nice contrast...crud-->ATF-->cotton. Also leave just enough of an oily film on the bores to prevent corrosion and provide a little lubrication.

These were pretty filthy.

Also going to take a second to talk about this slide hammer.

I knew I was going to want one of these to pull the intermediate shaft. I went to all my local stores (in no particular order- Autozone, Harbor Freight, O'Reilly, NAPA, Home Depot) and nobody had a cheap slide hammer/dent puller.

All anyone had was ~$90 automotive specific slide hammer kit which was going to be way overkill.

I scored this little bastard off ebay for $19 shipped. I love it because I don't think i'm going to have to weld a nut to the end of it, like they did in the evomoto clutch install article. There is collet that goes around the end that allows you to first place your M8 x 1.25 bolt in there and then cinch it on with the collet. This was great, because #1, I don't yet own a welding setup, and #2, I should be able to get some more use out of this tool rather than turning it into a one trick pony.

Here's a link to the install article http://www.evomoto.com/tech_articles..._article_id=27

And here's a link to the slide hammer on ebay: https://www.ebay.com/itm/DENT-PULLER...72.m2749.l2649

Last night after work, finally got the engine on the stand. Took a couple more pictures to better illustrate the setup.

The old engine/trans combo will come out of the car, and then temporarily live on that creeper, in the corner under the bench.

The new engine currently resides on the stand. (btw- my aging phone needs to be put out of its misery. It's challenging getting this thing to stay in focus. Apologies for the blurry photos, I will work on this :/

Once the engine was on the stand, it was time for my favorite thing, MORE CLEANING. This is a constant.

The new shortblock did not come very well sealed. It was in a plastic bag, which had been opened and then shoddily re-taped together at some point. But when you have to wait 5 weeks for them to get the damn thing over here from JP, and you're working with a deadline, you have to weigh that.

I took a few engines classes about 10 years ago. One thing that stuck with me was that ATF and clean, white cotton works great for cleaning the cylinder bores. The ATF really helps the cotton pick up any crud and provides a nice contrast...crud-->ATF-->cotton. Also leave just enough of an oily film on the bores to prevent corrosion and provide a little lubrication.

These were pretty filthy.

Also going to take a second to talk about this slide hammer.

I knew I was going to want one of these to pull the intermediate shaft. I went to all my local stores (in no particular order- Autozone, Harbor Freight, O'Reilly, NAPA, Home Depot) and nobody had a cheap slide hammer/dent puller.

All anyone had was ~$90 automotive specific slide hammer kit which was going to be way overkill.

I scored this little bastard off ebay for $19 shipped. I love it because I don't think i'm going to have to weld a nut to the end of it, like they did in the evomoto clutch install article. There is collet that goes around the end that allows you to first place your M8 x 1.25 bolt in there and then cinch it on with the collet. This was great, because #1, I don't yet own a welding setup, and #2, I should be able to get some more use out of this tool rather than turning it into a one trick pony.

Here's a link to the install article http://www.evomoto.com/tech_articles..._article_id=27

And here's a link to the slide hammer on ebay: https://www.ebay.com/itm/DENT-PULLER...72.m2749.l2649

The following users liked this post:

MRdarwin (Jun 30, 2019)

The following users liked this post:

MRdarwin (Jun 30, 2019)

#6

EvoM Guru

iTrader: (12)

A lot of positive energy here. Great setup and we look forward to your build. When you say new factory longblock, will you be reusing the oem crank, rods, and pistons and just replace the rings, bearings, main and rod bolts? Now that you have two shortblocks and two cylinder heads, you can experiment. With that extra 4g63 block, you can build a mild stroker for some reliability (2.1L) or a 2.0LR for better rod ratio than stock.  You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

#7

Thanks man!

Thanks! I'm pretty stoked on this whole thing  You nailed it- I'll be doing something a bit more radical with my original longblock. First we'll tear it down and see what's going on, and which parts are serviceable. Definitely looking forward to experimenting with it!!!!

You nailed it- I'll be doing something a bit more radical with my original longblock. First we'll tear it down and see what's going on, and which parts are serviceable. Definitely looking forward to experimenting with it!!!!

I bought a brand new shortblock from Mitsubishi. For posterity, here is a detailed list of what anybody can expect to receive when they order this p/n, MN158029. All new:

block, crank, rod set, bearing set, piston set, ring set, oil squirter set, main caps/girdle, core plugs/freeze plugs, other plugs (like for oil galleries), balance shaft bearings (shafts sold separately), head and transaxle alignment dowels and all associated fasteners. AND, IT COMES FULLY ASSEMBLED.

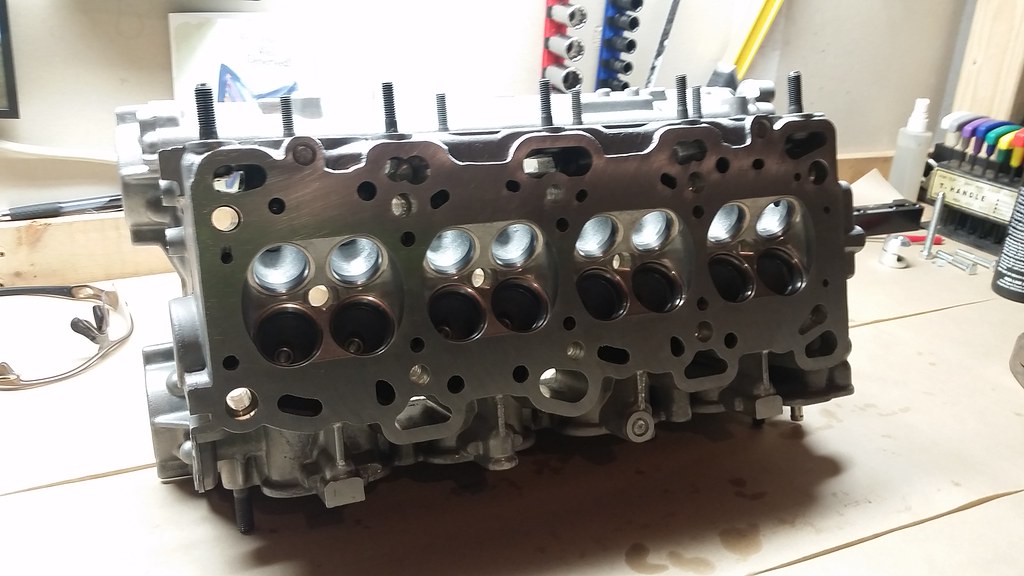

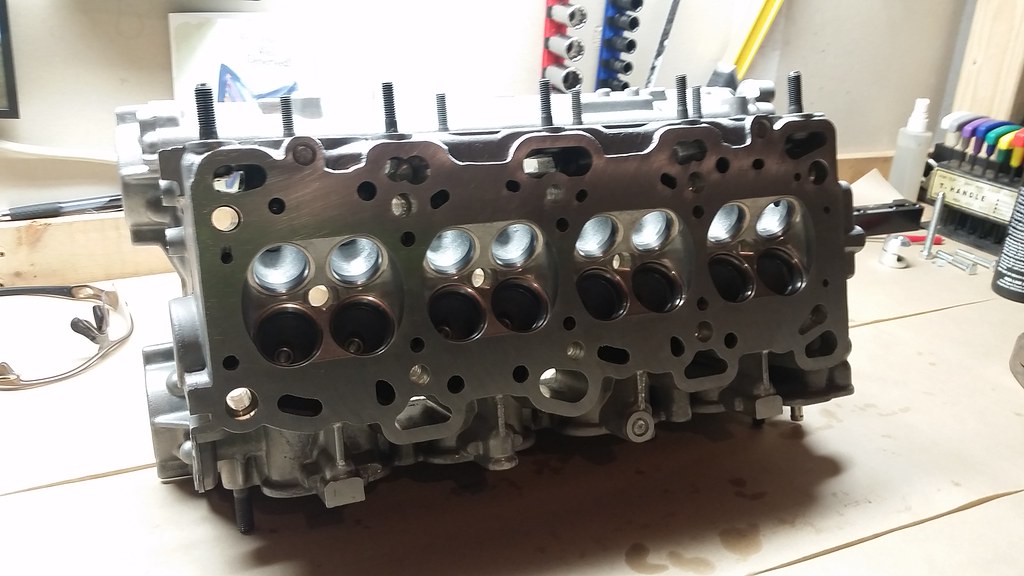

I also ordered a brand new cylinder head. In this case, the head is totally bare. I bought new OEM valves, springs, spring seats, retainers, and keepers. I also bought a set of billet GSC S1s. I will be using factory head bolts and head gasket. As for timing components, again all genuine Mitsu stuff, only variation will be a IX timing belt.

I also bought new balance shafts (WTF lol) and a new oil pump. (dude, you bought new balance shafts?) My two previous 1g/GVR4 4G63s both had BSE kits...so it was really weird buying new balance shafts. I'm a fan of balance shafts these days. Perhaps my original balance shafts are serviceable, but I wanted to be prepared for any eventuality. I've heard a few times now from a few 4G63 builders that sometimes balance shafts come out of otherwise good engines looking like hell.

For the most part, I wanted to just build a brand new engine as it would have come from the factory. My thought process was that I managed to get 115k out of the original engine in spite of a significant power increase and track use, and save for a busted thermostat, I probably would have got a whole ton more miles out of it (we'll know the score for real when I tear it down) based on oil analysis over the years and strong compression numbers at 115k. This tells me that the factory engines last a long time and are pretty reliable.

I'm down for aftermarket parts, and trying to find a good local machinist, but it seems like even the best local machine shops are not 100% perfect all the time, and neither are parts manufacturers. I'm cool with all that, but I feel the need to be prepared for some potential delays there that I just don't really want to mess with at the moment. We can expect a certain level of QC with regard to factory parts and machine work. Not to say that there aren't guys who do it even better, but perhaps it's more difficult to find that guy and then catch him on a good day, or whatever. And kinda the same for aftermarket parts.

A lot of positive energy here. Great setup and we look forward to your build. When you say new factory longblock, will you be reusing the oem crank, rods, and pistons and just replace the rings, bearings, main and rod bolts? Now that you have two shortblocks and two cylinder heads, you can experiment. With that extra 4g63 block, you can build a mild stroker for some reliability (2.1L) or a 2.0LR for better rod ratio than stock.  You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work.

You could also source a junkyard 4g64 block and build a 2.2LR or 2.4LR. A lot of the parts are interchangeable since the 4g63/4 are from the same iron casting but with different finishing machine work. You nailed it- I'll be doing something a bit more radical with my original longblock. First we'll tear it down and see what's going on, and which parts are serviceable. Definitely looking forward to experimenting with it!!!!

You nailed it- I'll be doing something a bit more radical with my original longblock. First we'll tear it down and see what's going on, and which parts are serviceable. Definitely looking forward to experimenting with it!!!!I bought a brand new shortblock from Mitsubishi. For posterity, here is a detailed list of what anybody can expect to receive when they order this p/n, MN158029. All new:

block, crank, rod set, bearing set, piston set, ring set, oil squirter set, main caps/girdle, core plugs/freeze plugs, other plugs (like for oil galleries), balance shaft bearings (shafts sold separately), head and transaxle alignment dowels and all associated fasteners. AND, IT COMES FULLY ASSEMBLED.

I also ordered a brand new cylinder head. In this case, the head is totally bare. I bought new OEM valves, springs, spring seats, retainers, and keepers. I also bought a set of billet GSC S1s. I will be using factory head bolts and head gasket. As for timing components, again all genuine Mitsu stuff, only variation will be a IX timing belt.

I also bought new balance shafts (WTF lol) and a new oil pump. (dude, you bought new balance shafts?) My two previous 1g/GVR4 4G63s both had BSE kits...so it was really weird buying new balance shafts. I'm a fan of balance shafts these days. Perhaps my original balance shafts are serviceable, but I wanted to be prepared for any eventuality. I've heard a few times now from a few 4G63 builders that sometimes balance shafts come out of otherwise good engines looking like hell.

For the most part, I wanted to just build a brand new engine as it would have come from the factory. My thought process was that I managed to get 115k out of the original engine in spite of a significant power increase and track use, and save for a busted thermostat, I probably would have got a whole ton more miles out of it (we'll know the score for real when I tear it down) based on oil analysis over the years and strong compression numbers at 115k. This tells me that the factory engines last a long time and are pretty reliable.

I'm down for aftermarket parts, and trying to find a good local machinist, but it seems like even the best local machine shops are not 100% perfect all the time, and neither are parts manufacturers. I'm cool with all that, but I feel the need to be prepared for some potential delays there that I just don't really want to mess with at the moment. We can expect a certain level of QC with regard to factory parts and machine work. Not to say that there aren't guys who do it even better, but perhaps it's more difficult to find that guy and then catch him on a good day, or whatever. And kinda the same for aftermarket parts.

The following users liked this post:

Pal215 (Jun 18, 2019)

Trending Topics

#8

Now here's the part where future visitors to this thread get to learn from my mistakes. I done f^cked up, folks.

NEVER clean your OEM headgasket with brake clean. If you knew that already, well I wish you had been here to stop me, because I didn't!

Holy cow what the heck was I thinking?! Well, the bag that my new OEM HG came in was a little tattered, and the HG itself didn't look immaculate, so after spending so much time cleaning the deck and other sensitive areas, I figured i'd better make sure it's clean. Well I can tell you that the rubbery/silicone/teflon/whatever it is that surrounds the fire rings does not play well with certain solvents, even our hippy CA grass fed, free range unicorn brake clean. As soon as I started spraying it, that stuff began deteriorating. I stopped immediately, but the damage was done. Maybe if I hadn't spent so much $ on everything else I'd send it but not today satan. So, HG #2 will be here Thursday :/

That was an expensive lesson. Please folks, if your HG packaging looks crappy, just refuse it and ask for another one or clean it very carefully. In hindsight, compressed air and a blow gun would have been a much better choice.

You can see all the black stuff on the butcher paper...that's that material from the fire rings.

NEVER clean your OEM headgasket with brake clean. If you knew that already, well I wish you had been here to stop me, because I didn't!

Holy cow what the heck was I thinking?! Well, the bag that my new OEM HG came in was a little tattered, and the HG itself didn't look immaculate, so after spending so much time cleaning the deck and other sensitive areas, I figured i'd better make sure it's clean. Well I can tell you that the rubbery/silicone/teflon/whatever it is that surrounds the fire rings does not play well with certain solvents, even our hippy CA grass fed, free range unicorn brake clean. As soon as I started spraying it, that stuff began deteriorating. I stopped immediately, but the damage was done. Maybe if I hadn't spent so much $ on everything else I'd send it but not today satan. So, HG #2 will be here Thursday :/

That was an expensive lesson. Please folks, if your HG packaging looks crappy, just refuse it and ask for another one or clean it very carefully. In hindsight, compressed air and a blow gun would have been a much better choice.

You can see all the black stuff on the butcher paper...that's that material from the fire rings.

#10

EvoM Guru

iTrader: (4)

I bought a brand new shortblock from Mitsubishi. For posterity, here is a detailed list of what anybody can expect to receive when they order this p/n, MN158029. All new:

block, crank, rod set, bearing set, piston set, ring set, oil squirter set, main caps/girdle, core plugs/freeze plugs, other plugs (like for oil galleries), balance shaft bearings (shafts sold separately), head and transaxle alignment dowels and all associated fasteners. AND, IT COMES FULLY ASSEMBLED.

block, crank, rod set, bearing set, piston set, ring set, oil squirter set, main caps/girdle, core plugs/freeze plugs, other plugs (like for oil galleries), balance shaft bearings (shafts sold separately), head and transaxle alignment dowels and all associated fasteners. AND, IT COMES FULLY ASSEMBLED.

#11

I ordered it through my work. We get our Mitsu stuff from Anaheim Mitsubishi. Parts manager over there, German M., nice guy to work with.

However, I've found the best pricing from Daytona Beach Mitsubishi. You might try them...Kameron and Chad were both very helpful. I would have ordered it from them, but on these heavy, expensive items I was not really interested in shipping them. Freight cost and potential for damage / resultant lost time made it a deal breaker. Cost should be in the neighborhood of $3k.

The following users liked this post:

Construct (Jun 19, 2019)

#12

So buying the complete shortblock was a big time saver. Still plenty to do though, so I assembled the new turbo and started cleaning parts. Just a low mileage FP 71HTA I picked up from a buddy for a great deal. Should be plenty for my modest goals and desire for a turbo with performance characteristics and appearance similar to stock.

I cleaned and bled the lifters per the FSM. Interesting discussion topic there. After some research, I decided to try it in accordance with the FSM.

The new head came coated to prevent corrosion (all the brown goop you can see in the pics in previous post), so I dropped that off at a machine shop down the street for a rejuvenating soak in their hot tank. Once it came back, I found some shipping damage on one of the corners...so rather than assembling the head that night, I got to work fixing that up. The most time consuming part was just prepping the head so that all the filings would not end up in the freshly cleaned head. :/ I also rigged up a shop vac as best I could to catch the majority of the filings. I took these pics prior to adding some more tape/rags.

Also, the surface finish on this brand new head wasn't great. Not bad enough to warrant re-surfacing.

*Edit* All of these scratches that were picked up by the camera flash pass the fingernail test, and can't be felt, at least by me anyway. Many can't even be seen unless you get the lighting just right. I just was expecting better. In school years ago I surfaced a 4G63 head...and by virtue of a really nice Rottler CNC machine was able to get that head like glass.

RA check

Milling

Ok, that's better. Now I can get to assembly.

Organize caps:

Install valve stem seals, then install valves.

I used the Euroexport valve spring compressor tool...worked great for me. There were some knockoffs on Ebay but I didn't want to give the copycats the business or f*ck around with potential quality issues.

Side note, OE exhaust valves are neat. Sodium filled for heat dissipation and you can clearly see the parting line about 2/3 up the stem. I wanted to use these because to me it's one of the reasons these cars are so badass...it's like part of the heritage and makes me feel warm and fuzzy, even if they aren't as lightweight or won't beat Brand X on the flowbench.

My updates here are coming very slowly.....my boxes of parts are actually quite a bit emptier now....you guys know how it is, making decent posts takes time and i'd rather spend that time out in the garage. Anyway, more to come!

I cleaned and bled the lifters per the FSM. Interesting discussion topic there. After some research, I decided to try it in accordance with the FSM.

The new head came coated to prevent corrosion (all the brown goop you can see in the pics in previous post), so I dropped that off at a machine shop down the street for a rejuvenating soak in their hot tank. Once it came back, I found some shipping damage on one of the corners...so rather than assembling the head that night, I got to work fixing that up. The most time consuming part was just prepping the head so that all the filings would not end up in the freshly cleaned head. :/ I also rigged up a shop vac as best I could to catch the majority of the filings. I took these pics prior to adding some more tape/rags.

Also, the surface finish on this brand new head wasn't great. Not bad enough to warrant re-surfacing.

*Edit* All of these scratches that were picked up by the camera flash pass the fingernail test, and can't be felt, at least by me anyway. Many can't even be seen unless you get the lighting just right. I just was expecting better. In school years ago I surfaced a 4G63 head...and by virtue of a really nice Rottler CNC machine was able to get that head like glass.

RA check

Ok, that's better. Now I can get to assembly.

Organize caps:

Install valve stem seals, then install valves.

I used the Euroexport valve spring compressor tool...worked great for me. There were some knockoffs on Ebay but I didn't want to give the copycats the business or f*ck around with potential quality issues.

Side note, OE exhaust valves are neat. Sodium filled for heat dissipation and you can clearly see the parting line about 2/3 up the stem. I wanted to use these because to me it's one of the reasons these cars are so badass...it's like part of the heritage and makes me feel warm and fuzzy, even if they aren't as lightweight or won't beat Brand X on the flowbench.

My updates here are coming very slowly.....my boxes of parts are actually quite a bit emptier now....you guys know how it is, making decent posts takes time and i'd rather spend that time out in the garage. Anyway, more to come!

Last edited by Apex Hunter; Jun 30, 2019 at 09:48 PM.

#15

Evolving Member

Haha no prob buddy , I saw this one pop up and it brought back memories lol. Iím glad I kept the car too , Iím also going to do a side project motor build here soon. Gotta pay some stuff off first but keep up the updates and lots of pics lol.