Evolution Dynamics Pikes Peak Build

#557

I asked for an engineering analysis of both cages. I don't need you to tell me what rally cages are.

I asked for an engineering analysis of both cages. I don't need you to tell me what rally cages are.Pictures will give you nothing, you have to look at it in person. You're assuming a lot of things. You're also assuming that I know nothing while you brush my comments aside.

Last edited by jons0n; Aug 30, 2012 at 06:00 AM.

#558

Evolving Member

iTrader: (4)

Join Date: Jan 2007

Location: Nebraska

Posts: 342

Likes: 0

Received 0 Likes

on

0 Posts

I asked for an engineering analysis of both cages. I don't need you to tell me what rally cages are.

I asked for an engineering analysis of both cages. I don't need you to tell me what rally cages are.Pictures will give you nothing, you have to look at it in person. You're assuming a lot of things. You're also assuming that I know nothing while you brush my comments aside.

FIA homologated cages, in order to obtain homologation, need to either be physically tested and shown to meet the FIA's minimum load requirements or in lieu of that engineering simulation data can be provided to the FIA to obtain homologation.

His cage is manufactured by Custom Cages UK and you can probably find the homologation forms on the FIA's website or request them from CC UK. You can read the FIA rule book to see the minimum load requirements.

And his cage is made of T45 which is a variety of CrMo with the advantage that it doesn't need to be normalized post-weld like garden varieties of CrMo. This might not hold in the US, but in Europe you have to have the cage certified and present the certificate at scrutineering, and as part of this the welder must submit a weld test to Custom Cages where it is destructively tested for weld quality before a cert is issued.

#559

Evolved Member

Thread Starter

Join Date: Mar 2004

Location: Dallas

Posts: 535

Likes: 0

Received 0 Likes

on

0 Posts

Thank you for that info WheelGap. It's certainly interesting how many different ways there are to skin a cat.

For everyone else: Let's try to keep this conversation on-topic and productive.

Thank You

For everyone else: Let's try to keep this conversation on-topic and productive.

Thank You

#560

Former Sponsor

iTrader: (56)

Join Date: Sep 2004

Location: DFW, TX

Posts: 2,701

Likes: 0

Received 0 Likes

on

0 Posts

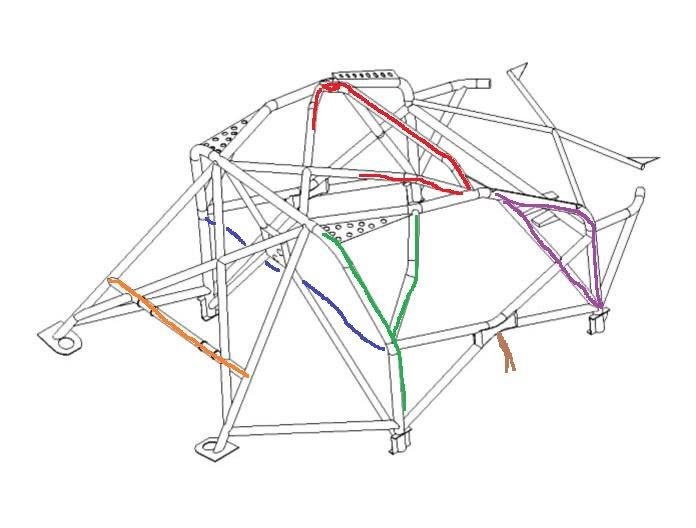

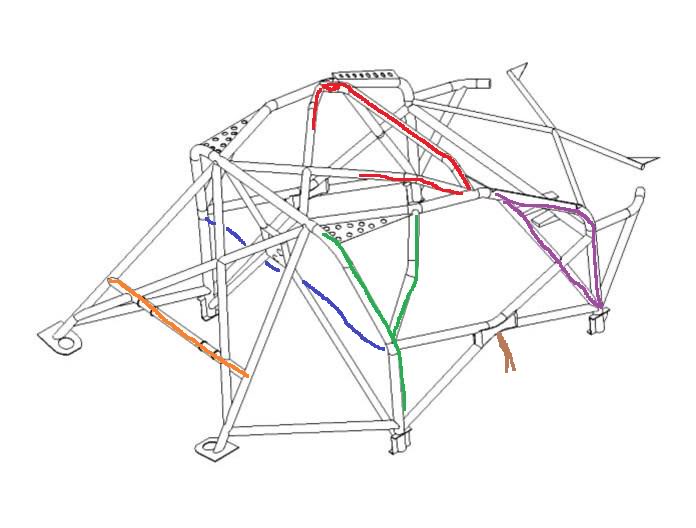

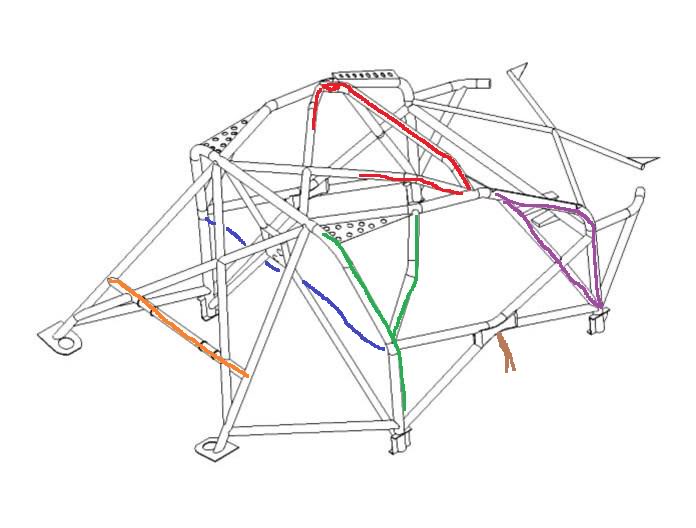

rob, you posted a picture of the homogulated evo rally cage, and i would like to point out some glaring flaws with the design. this might point you into some reasoning behind me not automatically building a rally cage in my next car.

basic cage design is to use triangles of course to give loads a path to follow and ultimately end at something solid, i.e. the pads into the floor, gussets on the roof, etc. there is nothing super advanced about it, its really a basic statics course for truss design in an undergraduate level engineering degree.

to start off, here is your cage you posted, and i have highlighted some tubes in color, and drew a couple colored lines to point out a few things.

first, something that didn't pertain to our crash at all, but is a poor design, is the rear strut brace colored in orange. it is poor practice to have tubes dead headed into main braces like the main hoop supports without any additional triangulation. especially one perpendicular like this one is. the reason its bad is, if you sustain a side impact, that tube will bend be in compression, and very easily collapse the opposite side support, rendering it very weak. the proper way to design the strut brace is to have it anchored as close as possible to the strut pad, and ideally directly onto it such that in an impact, its pushing on the pad, not another tube.

second thing i see as a design flaw, and directly pertained to our crash is the front windscreen "halo" bar, colored in red. the worse thing you can do with a tube is have free bends with no triangulation. it makes the tubes very weak if they are designed to be in compression, which this tube is. having two bends to hug the roof line i makes the tube far weaker then had it been simply a straight tube. if it see a very large compressive force, it will collapse at the bend, rather then transfer the forces to the node where it is welded to, and ideally down more triangles to the anchor points.

here is what my roof bar did to the opposite side of the cage due to compressive forces:

you can see the bar literally pushed right into the forward hoop from the lateral force it sustained. the lateral force is something i personally beleive the cage you have show also does nothing to address either. here is what im refering too:

the most damage to my cage was done laterally along the leading edge of the roofline. it deflected laterally about 7.5". it compressed downward only about 2-3" (despite some claims on 12" or more) the ONLY thing that would have reduced or prevented this would be something like the australian v8 supercar cage windscreen diagonals like below:

also, DaveK had some gusseting in the upper corners of his which would have helped, but still wouldn't have been as good as the AV8SC diagonal brace. both the rally cage you show, and mine had nothing in this area to prevent this type of deflection. since the forward hoop would have been in bending, thats exactly what it did. it bent along the line it was braced too:

since the dual A pillar tubes on your rally cage marked in purple would have both been in bending modes, i would argue in THIS crash, it wouldn't have faired any better then ours, and i would further argue that due to the dual bends in the roof line bar, it would have collapsed even farther then mine from having a weaker triangulation in the lateral deflection.

staying with the dual A pillar brace, the biggest problem i have with it is the angle at which it sits. i see, and understand, one of the points of it. however the implementation is pretty bad IMO. because the angles it creates with the actual forward hoop are so sharp (almost parallel), it doesn't offer much additional in the form of compressive force strength in the case of a crash landing on the roof (and in fact, its at such an angle its still almost in a bending mode rather then a compressive load). for the A-pillar brace to be stronger, it would need to be pretty much vertical (i have seen some cages that have it sitting vertical). so as it sits, the roll this tube plays is more in effectively reducing the length of the door bars rather then strengthing the roof line.

next on the list is the lack of a "harness bar" tube (colored in blue on your picture). this is something that i feel was extremely useful in our cage. however, had i done it again, i would have raised this bar further up and tried to place it directly at the bend on the main hoop. in our cage, this tube was in tension from the main hoop trying to bend outward. as seen here:

without this tube, the outward bending would have been far greater. the rally cage you have provided, didn't have any transverse tubes at this bend, and very likely would have suffered far more damage from the main hoop bending (i.e. an untriangulated bend). i'm guilty as well for not triangulating my main hoop in this place though, thus why it crushed there. again though, i did have triangulation to the rear driver side strut which greating reduced the damage done. total deflection for my main hoop was forward 2" and down 2.5" (essentially following the tangent of the triangulated tubes) here is an example of a cage with the triangulation laterally on the main hoop without a harness bar:

looking at this picture, i love how they have used the two traingulating tubes to protect from B-pillar intrusion at the same node, along with the bend on the main hoop and the lateral triangle tube. IMO thats exactly how it should be and i plan on doing something along the lines of this.

a minor thing with the rally cage, colored in green, is the out of plane main hoop. IMO this makes it weaker, although because it does have some triangulation with one of the X door bars, it isn't that bad.

last, is something the cage in this picture also uses:

all the vertical supports the door bars have are anchored to the floor. i will be doing at least one of these from now on. it never crossed my mind, but looking at how long my door bars, as well as the door bars in your rally cage (i marked what i would do in brown), its a long moment for bending in a side impact making it rather weak. because my nascar style bars have several bends in them, they arent as strong as the X bars. however they are inherently farther away from the passenger so they have more room to "give" which is exactly what happened in mine. with the anchors to the floor though, it will make this much stronger for either the X configuration or the NASCAR configuration.

my seats in the furture will be either using the OEM anchor points or i will be integrating it into the cage in some form or another.

lets see if we can keep this civil. feel free to pick apart what you would change with my cage, and explain why. i don't want to hear how only people with rally experience should be doing pikes peak though, and how you think jeremy wasnt qualified because he has never done a hill climb etc. that isn't constructive criticism for safety and only makes me very angry at you so lets make up, and make real engineering designs based off what is presented in front of me

so lets make up, and make real engineering designs based off what is presented in front of me

basic cage design is to use triangles of course to give loads a path to follow and ultimately end at something solid, i.e. the pads into the floor, gussets on the roof, etc. there is nothing super advanced about it, its really a basic statics course for truss design in an undergraduate level engineering degree.

to start off, here is your cage you posted, and i have highlighted some tubes in color, and drew a couple colored lines to point out a few things.

first, something that didn't pertain to our crash at all, but is a poor design, is the rear strut brace colored in orange. it is poor practice to have tubes dead headed into main braces like the main hoop supports without any additional triangulation. especially one perpendicular like this one is. the reason its bad is, if you sustain a side impact, that tube will bend be in compression, and very easily collapse the opposite side support, rendering it very weak. the proper way to design the strut brace is to have it anchored as close as possible to the strut pad, and ideally directly onto it such that in an impact, its pushing on the pad, not another tube.

second thing i see as a design flaw, and directly pertained to our crash is the front windscreen "halo" bar, colored in red. the worse thing you can do with a tube is have free bends with no triangulation. it makes the tubes very weak if they are designed to be in compression, which this tube is. having two bends to hug the roof line i makes the tube far weaker then had it been simply a straight tube. if it see a very large compressive force, it will collapse at the bend, rather then transfer the forces to the node where it is welded to, and ideally down more triangles to the anchor points.

here is what my roof bar did to the opposite side of the cage due to compressive forces:

you can see the bar literally pushed right into the forward hoop from the lateral force it sustained. the lateral force is something i personally beleive the cage you have show also does nothing to address either. here is what im refering too:

the most damage to my cage was done laterally along the leading edge of the roofline. it deflected laterally about 7.5". it compressed downward only about 2-3" (despite some claims on 12" or more) the ONLY thing that would have reduced or prevented this would be something like the australian v8 supercar cage windscreen diagonals like below:

also, DaveK had some gusseting in the upper corners of his which would have helped, but still wouldn't have been as good as the AV8SC diagonal brace. both the rally cage you show, and mine had nothing in this area to prevent this type of deflection. since the forward hoop would have been in bending, thats exactly what it did. it bent along the line it was braced too:

since the dual A pillar tubes on your rally cage marked in purple would have both been in bending modes, i would argue in THIS crash, it wouldn't have faired any better then ours, and i would further argue that due to the dual bends in the roof line bar, it would have collapsed even farther then mine from having a weaker triangulation in the lateral deflection.

staying with the dual A pillar brace, the biggest problem i have with it is the angle at which it sits. i see, and understand, one of the points of it. however the implementation is pretty bad IMO. because the angles it creates with the actual forward hoop are so sharp (almost parallel), it doesn't offer much additional in the form of compressive force strength in the case of a crash landing on the roof (and in fact, its at such an angle its still almost in a bending mode rather then a compressive load). for the A-pillar brace to be stronger, it would need to be pretty much vertical (i have seen some cages that have it sitting vertical). so as it sits, the roll this tube plays is more in effectively reducing the length of the door bars rather then strengthing the roof line.

next on the list is the lack of a "harness bar" tube (colored in blue on your picture). this is something that i feel was extremely useful in our cage. however, had i done it again, i would have raised this bar further up and tried to place it directly at the bend on the main hoop. in our cage, this tube was in tension from the main hoop trying to bend outward. as seen here:

without this tube, the outward bending would have been far greater. the rally cage you have provided, didn't have any transverse tubes at this bend, and very likely would have suffered far more damage from the main hoop bending (i.e. an untriangulated bend). i'm guilty as well for not triangulating my main hoop in this place though, thus why it crushed there. again though, i did have triangulation to the rear driver side strut which greating reduced the damage done. total deflection for my main hoop was forward 2" and down 2.5" (essentially following the tangent of the triangulated tubes) here is an example of a cage with the triangulation laterally on the main hoop without a harness bar:

looking at this picture, i love how they have used the two traingulating tubes to protect from B-pillar intrusion at the same node, along with the bend on the main hoop and the lateral triangle tube. IMO thats exactly how it should be and i plan on doing something along the lines of this.

a minor thing with the rally cage, colored in green, is the out of plane main hoop. IMO this makes it weaker, although because it does have some triangulation with one of the X door bars, it isn't that bad.

last, is something the cage in this picture also uses:

all the vertical supports the door bars have are anchored to the floor. i will be doing at least one of these from now on. it never crossed my mind, but looking at how long my door bars, as well as the door bars in your rally cage (i marked what i would do in brown), its a long moment for bending in a side impact making it rather weak. because my nascar style bars have several bends in them, they arent as strong as the X bars. however they are inherently farther away from the passenger so they have more room to "give" which is exactly what happened in mine. with the anchors to the floor though, it will make this much stronger for either the X configuration or the NASCAR configuration.

my seats in the furture will be either using the OEM anchor points or i will be integrating it into the cage in some form or another.

lets see if we can keep this civil. feel free to pick apart what you would change with my cage, and explain why. i don't want to hear how only people with rally experience should be doing pikes peak though, and how you think jeremy wasnt qualified because he has never done a hill climb etc. that isn't constructive criticism for safety and only makes me very angry at you

so lets make up, and make real engineering designs based off what is presented in front of me

so lets make up, and make real engineering designs based off what is presented in front of me

#561

Evolved Member

iTrader: (16)

Thanks for this post, it is a really good one.

i did presented why i thought the extra a pillar would be nice. Despite the additional weight.

As i said you guys build what you want. I do hope you will never will proove me wrong ( no more crash to really test a design)

( no more crash to really test a design)

I hope i can see your new car next year in person

Mean time jeremy can come up to run some hill climbs with us. Next stop is NC chase of the dragon.

Also dont get angry, i am only try to share my experince what i saw and experienced in my 20 + year on public road racing...

and as much as dummy i sound in enhglish, you might find some interesting things what i can contribute.

You dont have to take it, i am only asking to considerit and think about it. It comes from experience from racing and learning from race teams.

where the engineers work put it on the test and reality.

Rob

Ps:

I have a blue bar. That drawing is a minimum cage blue print for rally

i did presented why i thought the extra a pillar would be nice. Despite the additional weight.

As i said you guys build what you want. I do hope you will never will proove me wrong

( no more crash to really test a design)

( no more crash to really test a design)I hope i can see your new car next year in person

Mean time jeremy can come up to run some hill climbs with us. Next stop is NC chase of the dragon.

Also dont get angry, i am only try to share my experince what i saw and experienced in my 20 + year on public road racing...

and as much as dummy i sound in enhglish, you might find some interesting things what i can contribute.

You dont have to take it, i am only asking to considerit and think about it. It comes from experience from racing and learning from race teams.

where the engineers work put it on the test and reality.

Rob

Ps:

I have a blue bar. That drawing is a minimum cage blue print for rally

Last edited by Robevo RS; Aug 30, 2012 at 02:39 PM.

#562

Now this is something we can go by

Rob, I'm sorry for being a jerk. It's just that I can't stand it when people jump to conclusions without any formal evidence or comparison.

The main reason I responded to you was to point out that you have no valid argument until an analysis such as this has been done.

My apologies for the harshness.

Rob, I'm sorry for being a jerk. It's just that I can't stand it when people jump to conclusions without any formal evidence or comparison.

The main reason I responded to you was to point out that you have no valid argument until an analysis such as this has been done.

My apologies for the harshness.

Last edited by jons0n; Aug 30, 2012 at 03:01 PM.

#563

Evolved Member

iTrader: (16)

Now this is something we can go by

Rob, I'm sorry for being a jerk. It's just that I can't stand it when people jump to conclusions without any formal evidence or comparison.

The main reason I responded to you was to point out that you have no valid argument until an analysis such as this has been done.

My apologies for the harshness.

Rob, I'm sorry for being a jerk. It's just that I can't stand it when people jump to conclusions without any formal evidence or comparison.

The main reason I responded to you was to point out that you have no valid argument until an analysis such as this has been done.

My apologies for the harshness.

I do understand the heat etc,

End of the day we are all going for a same goal. Have good and fun races safely and watch out for each other. That doesnt always going quiet though.

As long as the respect is there from all side we are all good. Certainly from my side i do respect ANY racers or shops as long as they do a same .

Rob

#564

Evolved Member

iTrader: (8)

You point out some great things and having some good discussion on cage design is a great idea.

I think the FIA "sunscreen" tube is actually tied into the unibody windshield edge, similar to the A-pillar reinforcement. This would actually increase its stiffness in bending that likely would have helped with that first big impact right onto the roof corner. It's not a windshield cross bar, but it is something to help increase stiffness there. Also the additional brace from the front plate to the halo is slightly out of plane so it would also increase the stiffness. The cage is also tied into the door seal in the same area. I think all these details combined would actually help reduce the chance of a halo collapse by a pretty large margin.

It may not be an issue with the FIA stuff, but some classes must uses cages designed strictly for safety and cannot add additional chassis stiffness beyond what is simply required to protect the occupants. That rear strut bar design could be simply to accommodate that kind of a requirement?

Something I've seen done in the combination of an X-door bar and NASCAR bars. The NASCAR bars are added strictly to absorb some of the energy of a side impact before it hits the actual cage and to help spread the load when it hits the actual cage. Let's face it, putting a tube in compression is a bad idea to start with, adding any kind of side load or minor damage to the tube will have a huge impact on the likelihood of it buckling.

The FIA cage also doesn't have a dash bar attached to the cage and looking at some of the damage, I almost wonder if it's a better idea to use the OEM dash bar mounting system, keeping it separate from the cage.

I think the FIA "sunscreen" tube is actually tied into the unibody windshield edge, similar to the A-pillar reinforcement. This would actually increase its stiffness in bending that likely would have helped with that first big impact right onto the roof corner. It's not a windshield cross bar, but it is something to help increase stiffness there. Also the additional brace from the front plate to the halo is slightly out of plane so it would also increase the stiffness. The cage is also tied into the door seal in the same area. I think all these details combined would actually help reduce the chance of a halo collapse by a pretty large margin.

It may not be an issue with the FIA stuff, but some classes must uses cages designed strictly for safety and cannot add additional chassis stiffness beyond what is simply required to protect the occupants. That rear strut bar design could be simply to accommodate that kind of a requirement?

Something I've seen done in the combination of an X-door bar and NASCAR bars. The NASCAR bars are added strictly to absorb some of the energy of a side impact before it hits the actual cage and to help spread the load when it hits the actual cage. Let's face it, putting a tube in compression is a bad idea to start with, adding any kind of side load or minor damage to the tube will have a huge impact on the likelihood of it buckling.

The FIA cage also doesn't have a dash bar attached to the cage and looking at some of the damage, I almost wonder if it's a better idea to use the OEM dash bar mounting system, keeping it separate from the cage.

#565

Evolved Member

iTrader: (16)

the FIA cage has a dash bar  look closer.

look closer.

RKT motors new build the Evo X FIA R4 (different coilover length specific cage) dash bar.

Keep in mind the FIA roll cages specifically designed and combined with a specific car body. So cage designs can be different with additional bars or less bars to have a same safety standards. So might some part doesnt "make sense" for a first look. But they have been tested before they got approved. That is why the document i posted before (grupe N homologation for the Evo) stating which parts can not be cut out or removed from the body shell to alow to work perfect with this cage designs. The cage is a PART of the body structure for safety in these cases. These cages can not be handeled as a tube frame, they need support from the body crushing zones. There is many test etc done before one design gets approved. Custom Cages and MML (former Ralliart UK) directly working with Mitsubishi to have these thing resolved. So after the new car realesed they already have an approved and working cage system for rally. Those cages gone through vigorous tests and scruteneering. Also these cages build and designed to have a maximum saftey with a minimal weight gain. Example the new grupe N Evo X builds allows skinnier floors panels to shave weights with these cages, after they got approved for that by FIA.

You guys talking about side impact. here is on example for a side impact test been made with a WRC cage (none EVO):

http://www.dynalook.com/8th-european...on1_Paper2.pdf

the deadliest accidents in rally is always the sudden stops. Roll overs very rearly causing death. Since the car rolls out the impact energy and slows down the car that way.

Just saying the FIA scruteneers the following motorsports. ( it is worth to look it up):

http://www.fia.com/en-GB/sport/champ...pionships.aspx

so when they are approve something that is works. Specially after decades of scruteneering in the motorsport as a head organization. They have a resources and engineers to do best of the best.

But you can get help and so from them too

http://www.mira.co.uk/our-services/m...ll-cage-design

look closer.

look closer. RKT motors new build the Evo X FIA R4 (different coilover length specific cage) dash bar.

Keep in mind the FIA roll cages specifically designed and combined with a specific car body. So cage designs can be different with additional bars or less bars to have a same safety standards. So might some part doesnt "make sense" for a first look. But they have been tested before they got approved. That is why the document i posted before (grupe N homologation for the Evo) stating which parts can not be cut out or removed from the body shell to alow to work perfect with this cage designs. The cage is a PART of the body structure for safety in these cases. These cages can not be handeled as a tube frame, they need support from the body crushing zones. There is many test etc done before one design gets approved. Custom Cages and MML (former Ralliart UK) directly working with Mitsubishi to have these thing resolved. So after the new car realesed they already have an approved and working cage system for rally. Those cages gone through vigorous tests and scruteneering. Also these cages build and designed to have a maximum saftey with a minimal weight gain. Example the new grupe N Evo X builds allows skinnier floors panels to shave weights with these cages, after they got approved for that by FIA.

You guys talking about side impact. here is on example for a side impact test been made with a WRC cage (none EVO):

http://www.dynalook.com/8th-european...on1_Paper2.pdf

the deadliest accidents in rally is always the sudden stops. Roll overs very rearly causing death. Since the car rolls out the impact energy and slows down the car that way.

Just saying the FIA scruteneers the following motorsports. ( it is worth to look it up):

http://www.fia.com/en-GB/sport/champ...pionships.aspx

so when they are approve something that is works. Specially after decades of scruteneering in the motorsport as a head organization. They have a resources and engineers to do best of the best.

But you can get help and so from them too

http://www.mira.co.uk/our-services/m...ll-cage-design

Last edited by Robevo RS; Aug 30, 2012 at 04:30 PM.

#566

Evolved Member

iTrader: (8)

The FIA GrpN cage does not appear to include a dash bar as part of the specification. However, like the harness bar, the spec is probably what they consider the minimum and adding a dash bar is likely to happen in all cases.

I was just pointing out that adding a dash bar but not connecting it into the door seal area could be giving up a lot of protection.

I was just pointing out that adding a dash bar but not connecting it into the door seal area could be giving up a lot of protection.

#567

Evolved Member

iTrader: (21)

Join Date: Mar 2006

Location: Denver, CO

Posts: 1,449

Likes: 0

Received 0 Likes

on

0 Posts

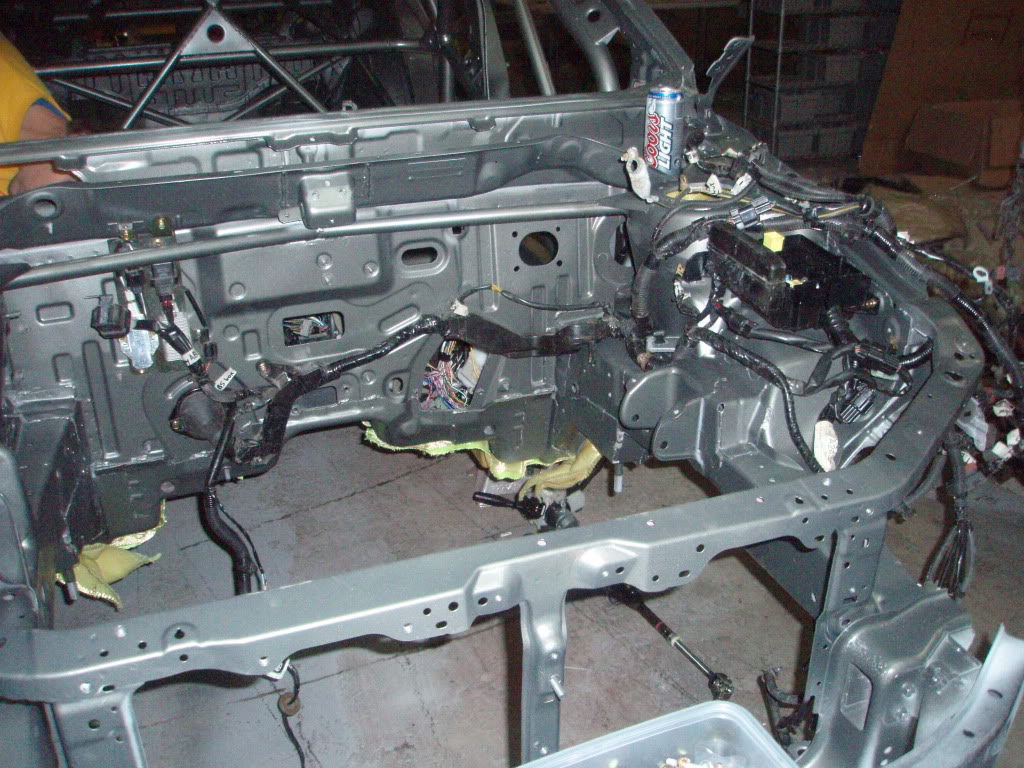

First off - cool post Kevin! (If there's any chance of shrinking down that photo of the roll cage on the table...it'd make this thread a bit easier to read.)

I'm actually the one with the cage shown, but that's a slightly older version of it.

My car actually does have a harness bar built into the 'main hoop' whereas the stick drawing has the older style harness bar that's 3' behind the driver. Part of the reason for the update as I understand it is that the use of HANS devices make shorter belts even more important.

Here's a few pics of my cage just after it first got painted back in 2008, for comparison purposes.

First up is a shot where you can see the different harness bar. If you look over to the passenger side, you can see the gusset plate on the door x/b-pillar. The upper diagonal bar that connects the halo bar to the main hoop is also zapped into the b-pillar. Also note that the cage kit comes with optional bars for doing seat mounts. Both sides of those bars use base plates to help spread the load where it attaches to the trans tunnell and sills.

There was a dash bar included with my kit, and in addition, there are extra smaller tubes that run through the firewall to tie into the strut towers, in addition to the thicker bars that are sort of extensions of the upper front door x beam which go through the firewall and are plated a the strut tower.

I don't have any good shots of the bar up along the windshield, but I just ran out and looked at the car and that bar is welded into the chassis in several spots.

I think one of the interesting discussion points may actually come down to different racing rule book philosophies. Its my understanding that many road race style cages are actually restricted in the amount of attachment points they can have with the chassis. Is that for fear of making the chassis too stiff which would give a handling advantage? (I'm not a road race guy, I don't know, just asking the question.)

All that said - I wouldn't have hesitated to hop in that car at any road race course in the country, it looked well designed and thought out for that purpose. I certainly don't want to just toss my car off a cliff for the fun of it, but I feel (I'm not an engineer but have watched lots of rally crash video compilations) that with the extra tie in points in an FIA cage, plus diagonal Xs in both the vertical main hoop and the rear stays and the 'doubling effect' of the a-pillar suport bar), I feel that a rally cage likely would've resisted buckling of the passenger side b-pillar better than a road race cage. My one major beef with my cage is that it doesn't contain a sill bar under the door x. In my BMW rally build I've added in this extra bar. I think this also gets at what Kevin is thinking in terms of being able to tie things into the floor so you don't have a stretch of 5' where the door bars aren't welded to anything.

I'm looking forward to seeing the stress analysis on both cages once you get thru the simulations Kevin. Thanks again for getting this thread back on track!

Dave

I'm actually the one with the cage shown, but that's a slightly older version of it.

My car actually does have a harness bar built into the 'main hoop' whereas the stick drawing has the older style harness bar that's 3' behind the driver. Part of the reason for the update as I understand it is that the use of HANS devices make shorter belts even more important.

Here's a few pics of my cage just after it first got painted back in 2008, for comparison purposes.

First up is a shot where you can see the different harness bar. If you look over to the passenger side, you can see the gusset plate on the door x/b-pillar. The upper diagonal bar that connects the halo bar to the main hoop is also zapped into the b-pillar. Also note that the cage kit comes with optional bars for doing seat mounts. Both sides of those bars use base plates to help spread the load where it attaches to the trans tunnell and sills.

There was a dash bar included with my kit, and in addition, there are extra smaller tubes that run through the firewall to tie into the strut towers, in addition to the thicker bars that are sort of extensions of the upper front door x beam which go through the firewall and are plated a the strut tower.

I don't have any good shots of the bar up along the windshield, but I just ran out and looked at the car and that bar is welded into the chassis in several spots.

I think one of the interesting discussion points may actually come down to different racing rule book philosophies. Its my understanding that many road race style cages are actually restricted in the amount of attachment points they can have with the chassis. Is that for fear of making the chassis too stiff which would give a handling advantage? (I'm not a road race guy, I don't know, just asking the question.)

All that said - I wouldn't have hesitated to hop in that car at any road race course in the country, it looked well designed and thought out for that purpose. I certainly don't want to just toss my car off a cliff for the fun of it, but I feel (I'm not an engineer but have watched lots of rally crash video compilations) that with the extra tie in points in an FIA cage, plus diagonal Xs in both the vertical main hoop and the rear stays and the 'doubling effect' of the a-pillar suport bar), I feel that a rally cage likely would've resisted buckling of the passenger side b-pillar better than a road race cage. My one major beef with my cage is that it doesn't contain a sill bar under the door x. In my BMW rally build I've added in this extra bar. I think this also gets at what Kevin is thinking in terms of being able to tie things into the floor so you don't have a stretch of 5' where the door bars aren't welded to anything.

I'm looking forward to seeing the stress analysis on both cages once you get thru the simulations Kevin. Thanks again for getting this thread back on track!

Dave

Last edited by DaveK; Aug 31, 2012 at 09:27 AM.

#568

Evolved Member

iTrader: (16)

The FIA GrpN cage does not appear to include a dash bar as part of the specification. However, like the harness bar, the spec is probably what they consider the minimum and adding a dash bar is likely to happen in all cases.

I was just pointing out that adding a dash bar but not connecting it into the door seal area could be giving up a lot of protection.

I was just pointing out that adding a dash bar but not connecting it into the door seal area could be giving up a lot of protection.

Same with a hight of the dash bar, its all about driver- co driver position. If you place your harness bar to high it might will fail inspection for the harness or will be uncomfortable for the crew.

Basically harness bars and dash bars are alway in the cars, but has no real blue print for them for a reasons and so above.

We do try to use the collepsable stock dash bar, but it was way to heavy, so we welded in a custom one. Rally cages are welded to the body countles points. Literally integrated to the body. Also before caging rally cars, they got seem welded every where. Shock towers got extra plating over the stock one etc. But the extra weight ( not much) well worth it. There are evo rally cars running around or below 2800 lbs legally.

Last edited by Robevo RS; Aug 31, 2012 at 04:15 AM.

#569

Former Sponsor

iTrader: (56)

Join Date: Sep 2004

Location: DFW, TX

Posts: 2,701

Likes: 0

Received 0 Likes

on

0 Posts

We cut the roof off of a wrecked evo 8 mr here. I still have the cross sections of the A-B-C pillars. They are reasonably strong and definitely good tie to for the cage (at least for the a pillar). The roof like for the evo 8/9 isn't at all strong though. It's a single piece of thin sheet metal folded and bonded to the roof. It wouldn't add any structural strength to the cage so I would Definately not consider it for added safety.

It's pretty visible in several pictures how badly it was crushed but once I get to the shop I'll get some pictures of the roof supports and all the pillar cross sections.

It's pretty visible in several pictures how badly it was crushed but once I get to the shop I'll get some pictures of the roof supports and all the pillar cross sections.

#570

Evolved Member

iTrader: (5)

On my dash bar , we cut all of the steering rack/petal assemblies off of the factory bar and welded it to the cage lateral in the same location where the factory bar sat. almost like a sleeve'. I was just looking to see if I had a pic of it or not on my phone... nope..

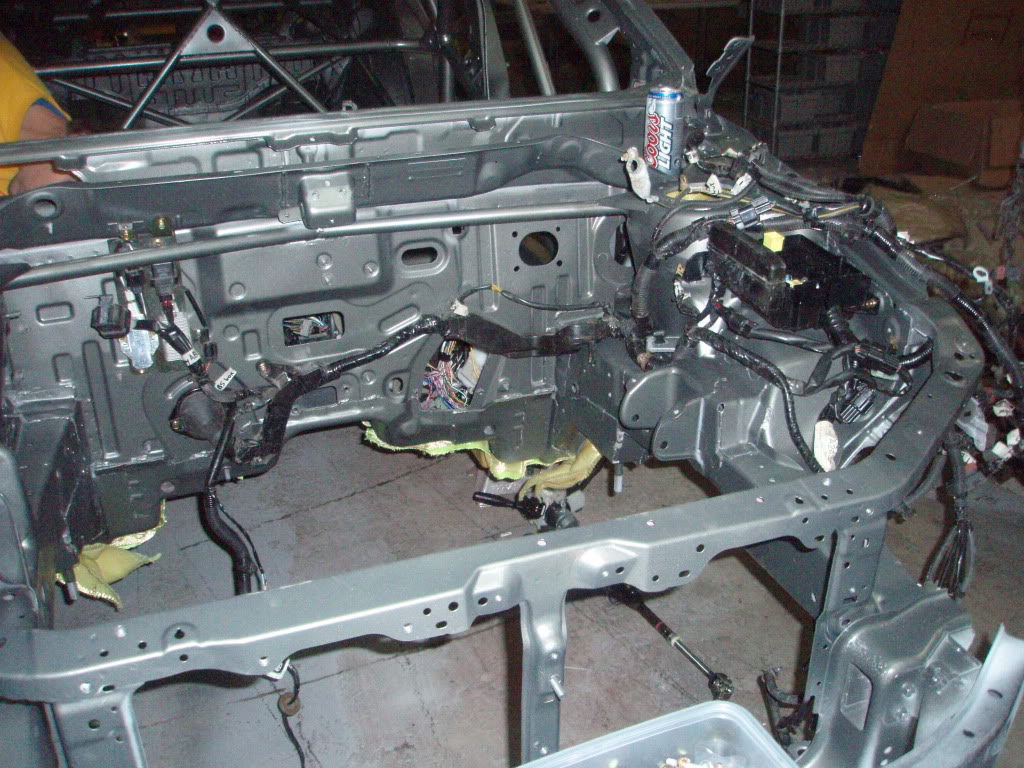

Here's a pic of gussets the fabricator did on the top of my A-Pillars. Mind you these pics were during progress of the construction of the cage, not the finished product.

Here's a pic of gussets the fabricator did on the top of my A-Pillars. Mind you these pics were during progress of the construction of the cage, not the finished product.