Hood vented downpipe with an electric cutout to dampen the noise!!!!! Who tried it???

#1

Hood vented downpipe with an electric cutout to dampen the noise!!!!! Who tried it???

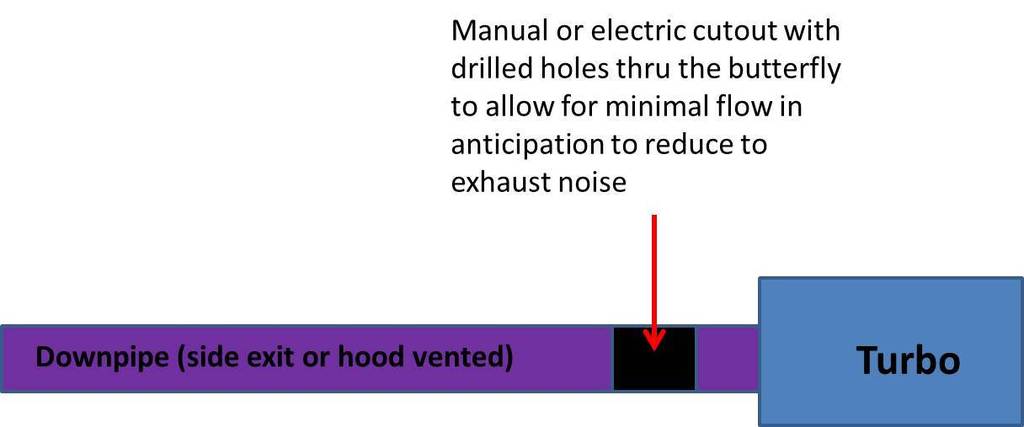

In pursue of weight reduction, I am considering to eliminate the exhaust system and rely on a hood vented downpipe. An electric cut-out would also be integrated inline to mask the noise when needed for example during warm-up, idle…etc

Question; has anyone tried such approach, and what are their thoughts on it? Would love to hear a clip of the sound difference and/or whether or not it’s worth the work.

Thx

DP

Question; has anyone tried such approach, and what are their thoughts on it? Would love to hear a clip of the sound difference and/or whether or not it’s worth the work.

Thx

DP

#2

EvoM Guru

iTrader: (1)

You're considering a hood exit exhaust, but are concerned with noise.

Also, I'm not sure what you plan on doing with the cutout in a 2ft long exhaust that already won't have a muffler..

Also, I'm not sure what you plan on doing with the cutout in a 2ft long exhaust that already won't have a muffler..

#4

Evolved Member

iTrader: (71)

I'm doing this soon, I have a top mount kit and will make a 90/120 degree v-band mandrel pipe exiting the hood with a Apexi cable-style ECV mounted to the end to remove 35-40lbs and make max power. I'll still have my 3" MAP/Varex exhaust to swap out when I feel like it.

#5

I am well aware of the noise guys!... I had a side exit exhaust in the past but only lasted for a couple of hrs before I decided to remove it so my neighbors don't hate me.

My thought with the cut-out is if we restrict the flow or deflect the sound waves backward, then we may be able to minimize the noise to an acceptable level.

NICE!... would love to see pics and get your feedback on it when its said and done. keep us posted!

My thought with the cut-out is if we restrict the flow or deflect the sound waves backward, then we may be able to minimize the noise to an acceptable level.

I'm doing this soon, I have a top mount kit and will make a 90/120 degree v-band mandrel pipe exiting the hood with a Apexi cable-style ECV mounted to the end to remove 35-40lbs and make max power. I'll still have my 3" MAP/Varex exhaust to swap out when I feel like it.

#6

EvoM Guru

iTrader: (1)

The cut out idea will not do anything for noise.

Trending Topics

#9

Evolving Member

Cutouts don't quiet exhausts down. They allow the airflow to be released prior to a restriction such as a muffler. This allows using a lot of restrictions (mufflers in this case) to quiet the exhaust down without impeding exhaust flow when the cutout is open.

You will not be able to quiet your exhaust just by adding a cutout. There's no room to add what you need to make it much quieter under the hood like you're asking either. I understand the desire for cheap weight savings but this just isn't a practical way to do it. An aluminum or titanium exhaust is light and would work but is expensive just for weight reduction. Dumping a bullet muffler or something under the car would work for cheap but would be loud.

Can't really have cheap, light, and quiet with exhausts. Pick two.

You will not be able to quiet your exhaust just by adding a cutout. There's no room to add what you need to make it much quieter under the hood like you're asking either. I understand the desire for cheap weight savings but this just isn't a practical way to do it. An aluminum or titanium exhaust is light and would work but is expensive just for weight reduction. Dumping a bullet muffler or something under the car would work for cheap but would be loud.

Can't really have cheap, light, and quiet with exhausts. Pick two.

#10

^ we'r trying to use the cut-out in its closed form to create or duplicate such a restriction that a typical muffler would to reduce the noise. I understand its function!

So you planning on running this manually with the cable? I am not familiar with the ER setup, so will def. look it up.

#11

Evolved Member

iTrader: (22)

1) Where is the exhaust gas then going?

2) Wherever it goes if you want noise reduction it's going to have to go through a muffler.

If #2 is what you are attempting to duplicate somehow it's going to take a lot more than a cut out and probably ends up weighing more than if you'd just run it to an off the shelf muffler. It may be that I am also missing what you are explaining.

Last edited by codgi; Oct 11, 2015 at 10:42 PM.

#14

Evolved Member

iTrader: (71)

That's how mine will be with my top-mount, only 12-18" 90, maybe 120 degree bend. I already have a Varex remote muffler exhaust that MAP built me and I wired it to run off a momentary switch rather than wireless remote. It opens way faster than QTP and other electronic valve cutouts but the cable will be even faster and easier to work with.

#15

Evolved Member

iTrader: (8)

Jesus people, if you don't understand what he's proposing, probably don't post.

Seems like there was a boost actuated version out there that used a wastegate actuator? You'd almost want a vacuum actuated version though that closed under vacuum but then was fully open at atmosphere and boost. Maybe a small add on spring to keep it from opening fully until a couple PSI but you'd want it at least partially open even under light throttle while having a bypass hole in the plate for idle.

That said, I was going to do a hood vent but it doesn't make sense at all to me on an EVO. With typical turbo placement, you have to wrap the pipe around like 130* and then it's pointing at the drivers side of the windshield. Personally, I'd hate to have it like that as it seems like if you had an engine/turbo failure, you are going to coat the drivers side of the windshield with oil/coolant. Maybe I'm crazy and it's a non-issue, but the time you'll have a motor failure is also probably the least desirable time to have the windshield coated in junk that makes it difficult to see (100+mph).

Then there is water intrusion. If it never sees rain, ok. But even if you use it for weekend cruising and you could find your self parked some where in a rain storm, dumping water straight down into the turbine wheel seems like a bad thing.

Personally, I'd use the same idea but do a bumper side exit setup (provided you don't have an oil cooler). Otherwise, just do mufflerless aluminum exhaust. It's still loud AF but it gets the noise out from under the car and doesn't punish you like an open downpipe does. You can do a turboback exhaust for about 12 pounds using 20G stainless for the downpipe and 16G aluminum for the catback.

Seems like there was a boost actuated version out there that used a wastegate actuator? You'd almost want a vacuum actuated version though that closed under vacuum but then was fully open at atmosphere and boost. Maybe a small add on spring to keep it from opening fully until a couple PSI but you'd want it at least partially open even under light throttle while having a bypass hole in the plate for idle.

That said, I was going to do a hood vent but it doesn't make sense at all to me on an EVO. With typical turbo placement, you have to wrap the pipe around like 130* and then it's pointing at the drivers side of the windshield. Personally, I'd hate to have it like that as it seems like if you had an engine/turbo failure, you are going to coat the drivers side of the windshield with oil/coolant. Maybe I'm crazy and it's a non-issue, but the time you'll have a motor failure is also probably the least desirable time to have the windshield coated in junk that makes it difficult to see (100+mph).

Then there is water intrusion. If it never sees rain, ok. But even if you use it for weekend cruising and you could find your self parked some where in a rain storm, dumping water straight down into the turbine wheel seems like a bad thing.

Personally, I'd use the same idea but do a bumper side exit setup (provided you don't have an oil cooler). Otherwise, just do mufflerless aluminum exhaust. It's still loud AF but it gets the noise out from under the car and doesn't punish you like an open downpipe does. You can do a turboback exhaust for about 12 pounds using 20G stainless for the downpipe and 16G aluminum for the catback.