Measured some swaybars, check my math

#1

Measured some swaybars, check my math

Hey guys, Iíve been trying to get a better understanding onthe balance we run between sway bar rates and springs rates to know what is anappropriate balance. If we double spring rates from stock, should we double barrates? If rates are limited by bumpy courses, how much will be lost in steadystate dropping spring rate and upping bar rate? To start understanding, I needto know what Iím actually running.

To start, I measured my stock FSB, estimated a re-drilledbar, and the whiteline 26mm bar all as well as I could. I had a resolution ofabout 1/8Ē. Using this equation:

500,000 D^4

K (lbs/in) = -------------------------------------

(0.4244 x A^2 x B) + (0.2264 x C^3)

B

-----_________________

A| /----------------------------\ C

| /------------------------------\

A - Length of end perpendicular to B (torque arm - inches)

B - Length of center section (inches)

C - Length of end (inches)

D - Diameter bar (inches)

The values I get are attached (Tried to embed them, but either I fail or the software does).

Some of the values, like A, I had to get indirectly bymeasuring the hole-hole difference and doing some math, but I feel comfortable theyíre all within 1/8Ē.

Iíve heard people say the whiteline bar is 38% stiffer, but Iímcalculating nearly double that. The 38% Iím assuming is just a check on the 24to 26mm dia change, but Iím finding both a change in ďAĒ and ďCĒ also.

Iím sharing this stuff both so we can all learn and forsomeone to double check my work. Am I right the Whiteline is significantlystiffer than just the diameter would indicate?

To start, I measured my stock FSB, estimated a re-drilledbar, and the whiteline 26mm bar all as well as I could. I had a resolution ofabout 1/8Ē. Using this equation:

500,000 D^4

K (lbs/in) = -------------------------------------

(0.4244 x A^2 x B) + (0.2264 x C^3)

B

-----_________________

A| /----------------------------\ C

| /------------------------------\

A - Length of end perpendicular to B (torque arm - inches)

B - Length of center section (inches)

C - Length of end (inches)

D - Diameter bar (inches)

The values I get are attached (Tried to embed them, but either I fail or the software does).

Some of the values, like A, I had to get indirectly bymeasuring the hole-hole difference and doing some math, but I feel comfortable theyíre all within 1/8Ē.

Iíve heard people say the whiteline bar is 38% stiffer, but Iímcalculating nearly double that. The 38% Iím assuming is just a check on the 24to 26mm dia change, but Iím finding both a change in ďAĒ and ďCĒ also.

Iím sharing this stuff both so we can all learn and forsomeone to double check my work. Am I right the Whiteline is significantlystiffer than just the diameter would indicate?

#4

Yeah, At first I was only looking at either "A" or "C" but it turns out cause we actually have a pretty shallow angle, and its different by a few degree's on each bar that it ends up mattering.

#5

Evolved Member

iTrader: (2)

or another away to think about it is you have 2 torsion bars connected together in the middle.

#6

what you've got is a torsion bar equation, i.e. you're getting lb/in if you hold one end of the swaybar fixed and move the other end 1 inch. if you're looking to calculate a wheel rate equivalent stiffness you need to take into account that both ends of the swaybar move.

or another away to think about it is you have 2 torsion bars connected together in the middle.

or another away to think about it is you have 2 torsion bars connected together in the middle.

Would you mind sharing what you have for swaybar motion ratio? If not, I still have to pull off springs to change rates and can take it through its range to make some measurements.

#7

Evolved Member

iTrader: (2)

for the front i use .6 but it was a really quick measurement. If you're going to have everything apart i'd probably still measure it again.

speaking of, it looks like the stiffness of the lever arms is almost equal to the stiffness of the torsion bar which totally ruins my world. LOL so i guess i'll be doing some more validation myself...

speaking of, it looks like the stiffness of the lever arms is almost equal to the stiffness of the torsion bar which totally ruins my world. LOL so i guess i'll be doing some more validation myself...

Trending Topics

#8

Alright, Just took front suspension through a 4" sweep with the top being nearly completely compressed.

It started at 0.562 and dropped to 0.54. Average through the sweep was 0.555. So 0.555^2 = 0.316. Total effect the sway bar is contributing stock seems to be pretty small, but I need to change my numbers (left them at work) to get an estimated % value which is overall what I'm looking for.

It started at 0.562 and dropped to 0.54. Average through the sweep was 0.555. So 0.555^2 = 0.316. Total effect the sway bar is contributing stock seems to be pretty small, but I need to change my numbers (left them at work) to get an estimated % value which is overall what I'm looking for.

#9

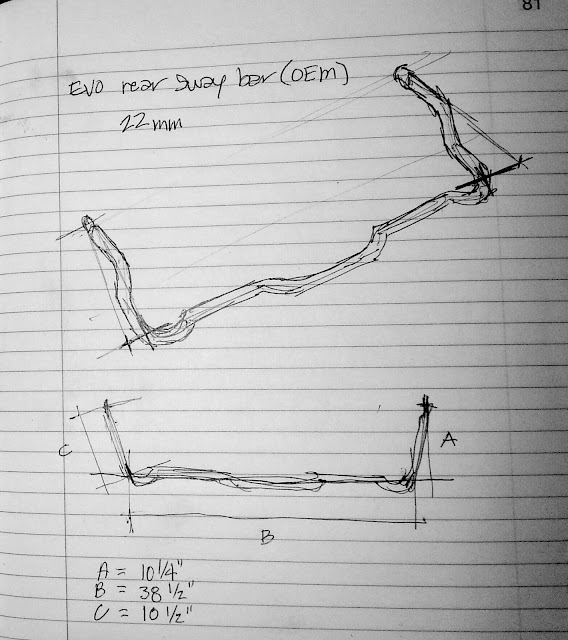

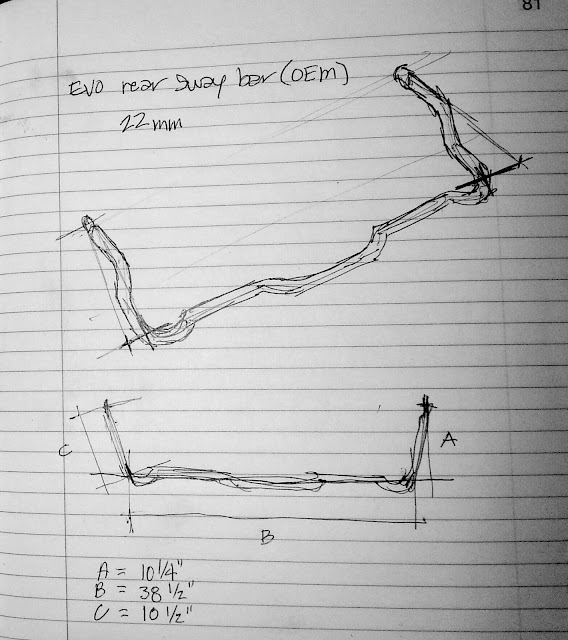

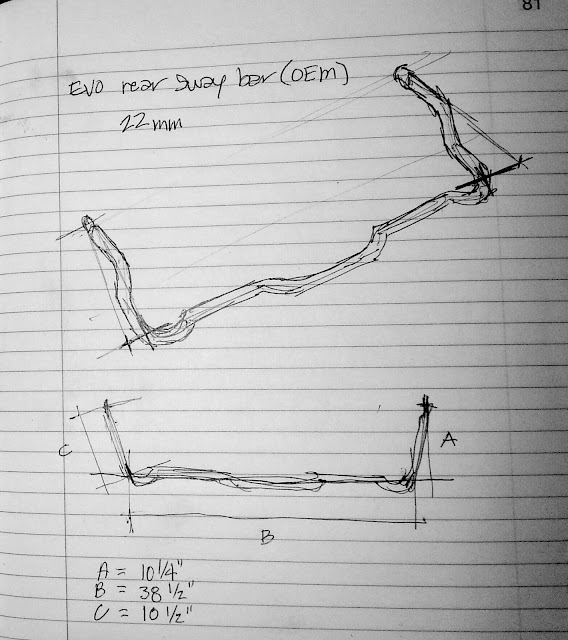

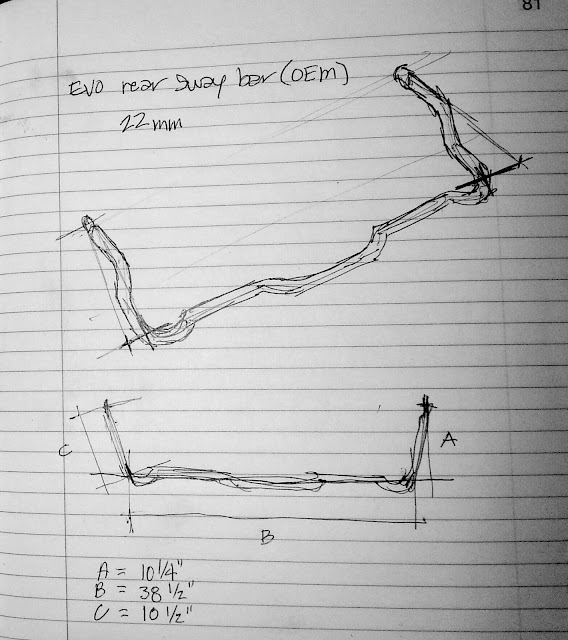

Measured the rear last night and found some interesting stuff.

Rear swaybar motion ratio is 0.69-0.71. Average through a 4" stroke was 0.70. Now with the stiffness of the rear bar coupled with the motion ratio, Stock front and rear bar have almost exactly the same effective wheel rate of 170lbs/in.

Rear swaybar motion ratio is 0.69-0.71. Average through a 4" stroke was 0.70. Now with the stiffness of the rear bar coupled with the motion ratio, Stock front and rear bar have almost exactly the same effective wheel rate of 170lbs/in.

#10

Evolving Member

nice, thanks for sharing Dallas. I dug out my stock rear bar and measured it on the bench the other night, here's what I found:

(500000*(0.866)^4)/((0.4244*10.25^2*38.5)+(0.2264*10.5^3))=142.21lb/in

which is less....

Hotchkis published their lb/in bar rates, also as a percentage over stock, using their 3 numbers and reverse mathing it (technical term) I came up with a claimed 150.14lb/in average.

[edit] and if I understand this right, wheel rate from my measurements, using your measured MR is:

((142.21*(.7^2))*2 = 139.37lb/in

(500000*(0.866)^4)/((0.4244*10.25^2*38.5)+(0.2264*10.5^3))=142.21lb/in

which is less....

Hotchkis published their lb/in bar rates, also as a percentage over stock, using their 3 numbers and reverse mathing it (technical term) I came up with a claimed 150.14lb/in average.

[edit] and if I understand this right, wheel rate from my measurements, using your measured MR is:

((142.21*(.7^2))*2 = 139.37lb/in

Last edited by 4wd4me; Jul 27, 2013 at 10:25 AM.

#11

nice, thanks for sharing Dallas. I dug out my stock rear bar and measured it on the bench the other night, here's what I found:

(500000*(0.866)^4)/((0.4244*10.25^2*38.5)+(0.2264*10.5^3))=142.21lb/in

which is less....

Hotchkis published their lb/in bar rates, also as a percentage over stock, using their 3 numbers and reverse mathing it (technical term) I came up with a claimed 150.14lb/in average.

[edit] and if I understand this right, wheel rate from my measurements, using your measured MR is:

((142.21*(.7^2))*2 = 139.37lb/in

(500000*(0.866)^4)/((0.4244*10.25^2*38.5)+(0.2264*10.5^3))=142.21lb/in

which is less....

Hotchkis published their lb/in bar rates, also as a percentage over stock, using their 3 numbers and reverse mathing it (technical term) I came up with a claimed 150.14lb/in average.

[edit] and if I understand this right, wheel rate from my measurements, using your measured MR is:

((142.21*(.7^2))*2 = 139.37lb/in

I also measure C different. Wondering if you are measuring from the bar by the bend and I'm measuring to the center of the bar at the mount.

I dont directly measure A, I actually just measure the total width of the bar at the endlink then back calculate A given B and C. I guess the only way to know for sure is to make a fixture and load it on my bench to see where between our numbers the actual value is.

#12

Evolved Member

iTrader: (1)

Oh, this looks fun!

With regard to what value you use for B, it's a question of whether you are calculating the effect of the bar on single-wheel bump or the effect of the bar on roll resistance. Bars are, as is well known, twice as effective for roll resistance than single-wheel bump. That's why there are two formula floating around, one that uses all of B and one that uses half of it.

With regard to what value you use for B, it's a question of whether you are calculating the effect of the bar on single-wheel bump or the effect of the bar on roll resistance. Bars are, as is well known, twice as effective for roll resistance than single-wheel bump. That's why there are two formula floating around, one that uses all of B and one that uses half of it.

#13

Evolved Member

iTrader: (8)

It would be interesting to see how close the real stiffness matches up with theory. I suspect the portion in the center of the bar that is not inline with the mounts actually has a signifigant impact on stiffness.

All the more reason to figure out how to put a true spline drive torsion bar in there...

All the more reason to figure out how to put a true spline drive torsion bar in there...

#14

It would be interesting to see how close the real stiffness matches up with theory. I suspect the portion in the center of the bar that is not inline with the mounts actually has a signifigant impact on stiffness.

All the more reason to figure out how to put a true spline drive torsion bar in there...

All the more reason to figure out how to put a true spline drive torsion bar in there...

#15

Evolved Member

iTrader: (8)

That's why it would be interesting. You're thinking it's not significant, I'm thinking it is.

Not on the level of significance of the bending that takes place in the arm section, but ~20%? Maybe.

I agree though, no point in FEA work when it would take about an hour on the bench.

Not on the level of significance of the bending that takes place in the arm section, but ~20%? Maybe.

I agree though, no point in FEA work when it would take about an hour on the bench.