Lets See Those Custom Parts v.2023

#76

Part of the reason I decided to make the uprights was that even if you had them in hand it wouldn't be realistic to make your own copy. And being as complicated as they are, theirs a lot of intent hidden in the design that would be lost to a copier. But at the end of the day, I cant patent it because patents don't work for people at our level.

This is just the name of the game in the aftermarket. If you (or I) come up with an idea, and its easy to make, it will be copied. If their are big margins on it, someone will make it cheaper.

I'm doing what I can to innovate on things but I can only guarantee I'm the first do to it.

This is just the name of the game in the aftermarket. If you (or I) come up with an idea, and its easy to make, it will be copied. If their are big margins on it, someone will make it cheaper.

I'm doing what I can to innovate on things but I can only guarantee I'm the first do to it.

#77

EvoM Guru

iTrader: (1)

Yeah. But you also didn't get mad at me when I said we plan on building a weldment upright when I get the cash together...lol

Also, you can't really patent a control arm. Every car comes with control arms.

Also, you can't really patent a control arm. Every car comes with control arms.

Last edited by letsgetthisdone; Mar 30, 2017 at 09:17 AM.

#78

Evolved Member

Part of the reason I decided to make the uprights was that even if you had them in hand it wouldn't be realistic to make your own copy. And being as complicated as they are, theirs a lot of intent hidden in the design that would be lost to a copier. But at the end of the day, I cant patent it because patents don't work for people at our level.

This is just the name of the game in the aftermarket. If you (or I) come up with an idea, and its easy to make, it will be copied. If their are big margins on it, someone will make it cheaper.

I'm doing what I can to innovate on things but I can only guarantee I'm the first do to it.

This is just the name of the game in the aftermarket. If you (or I) come up with an idea, and its easy to make, it will be copied. If their are big margins on it, someone will make it cheaper.

I'm doing what I can to innovate on things but I can only guarantee I'm the first do to it.

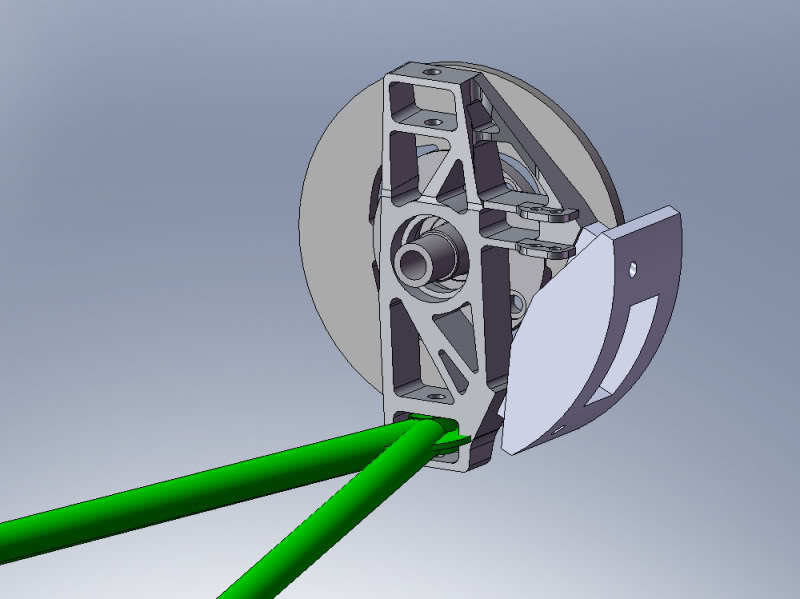

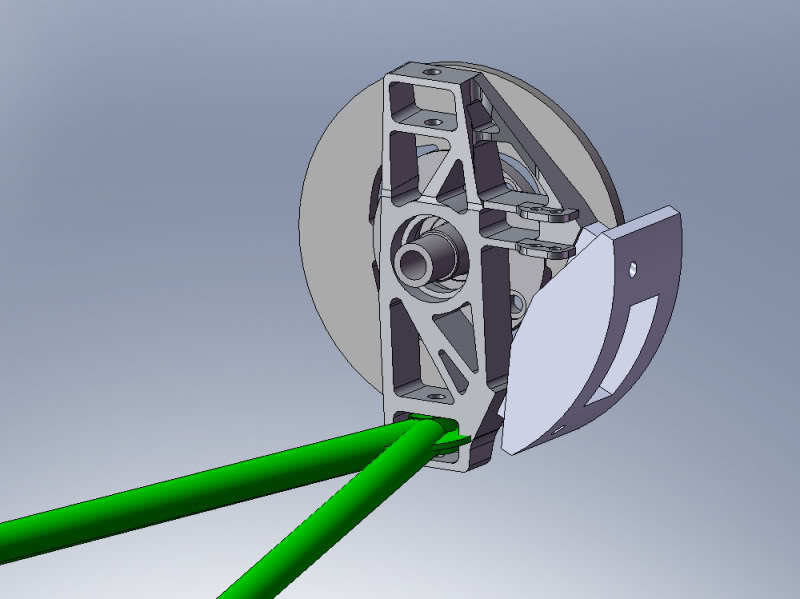

letsgetthisdone, I am not dissing your solution, I am just trying to have an engineering discussion on possible movement in a piece of bent tubing when under 2000+ N of force.. As I am designing my own front arms (disclamer, not copying anyone

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

#79

EvoM Guru

iTrader: (1)

letsgetthisdone, I am not dissing your solution, I am just trying to have an engineering discussion on possible movement in a piece of bent tubing when under 2000+ N of force.. As I am designing my own front arms (disclamer, not copying anyone  ) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..I know you're not. Flex concerns is why went so thick on wall thickness.

#80

letsgetthisdone, I am not dissing your solution, I am just trying to have an engineering discussion on possible movement in a piece of bent tubing when under 2000+ N of force.. As I am designing my own front arms (disclamer, not copying anyone  ) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

) keeping things stiff is on top of my priority. It will be good to hear how the car bahaves with it..

#81

EvoM Guru

iTrader: (1)

Hey now, I never got mad about that. I'm more interested in seeing what your guy comes up with. Just like my new control arms, I certainly could have made them from steel in a weldment, aluminum is just more fun and cool to me.

Its certainly something I would run FEA on, but I have the R/TErnie arms on my car for like 5 years without issue.

Its certainly something I would run FEA on, but I have the R/TErnie arms on my car for like 5 years without issue.

****, sorry. That was a typo. I definitely meant that you didn't* get mad...lol.

You definitely seem on the side of just seeing other progress. Hence sending me the dxf file to get top plates cut for my ohlins (thanks again btw

).

).We could FEA them in solidworks, but not really sure of the forces they see from the rear tire. They mostly just hold the wheel fore/aft. So mostly just accel and braking forces.

#82

Evolved Member

yes, it depends on what sort of machinery and service you have... I am having huge problems getting a good CNC shop for milling and turning.. on the other hand, I can tig weld and have great suppliers for laser cutting so most my stuff tends to use that technology...

I have a upright design for my single seater all ready to cut... but Evo needs to be finished first..

Speaking of custom uprights.. IMHO it is a slippery slope, as then there are stiffer ways of attaching things, like struits and going for direct fit of radial calipers... all leading to more fabrication..

I have a upright design for my single seater all ready to cut... but Evo needs to be finished first..

Speaking of custom uprights.. IMHO it is a slippery slope, as then there are stiffer ways of attaching things, like struits and going for direct fit of radial calipers... all leading to more fabrication..

#83

Evolved Member

I am not saying it will break, for sure not... I would say that on corner exit you might see 0.5 G, for example, under accel, and about 25%, or a bit more, will be pushing that wheel forward... so, 2000 N maybe?

#84

EvoM Guru

iTrader: (1)

I'll take that 2000N figure to the fab guy and have him run it, see what happens.

Direct mount of a radial caliper is something I would like to incorporate in mine. Which will simply lead to needing more money for the project...

Direct mount of a radial caliper is something I would like to incorporate in mine. Which will simply lead to needing more money for the project...

#85

EvoM Guru

iTrader: (1)

I was able to make it flex a smidge when tightening the ball joint. I was using a 3ft long crescent wrench, and putting most of my 240lbs body weight on it though, so conservatively, a lot of torque...LOL. That is also a twisting force working on the bend vs a straight pull or push. So, I'm not sure how that would translate.

#88

EvoM Guru

iTrader: (1)

Yeah, 4130 Chromoly, USA sourced...

Cool. We'll see if they stay together this weekend. Then we can run an FEA next week lol

#89

Evolved Member

iTrader: (15)

Agreed on all fronts. Any manufacturing wither auto or home ends up getting copied anyway mostly offshore and you simply can't compete with it at the end of the day. I really like what we're doing here and keeping it close because once you try to brand and sell it elsewhere you end up spending more then you make it seems...unless it's really out there and groundbreaking. Take the racefab pan I added - another fellow track member figured out how to do it cheaper by a bit because he didn't want to deal with xyz. If you want something bad enough you find a way of getting it done yourself usually.

Whats really dangerous is most of us are engineering geeks and have a geeky platform to work on so someday ya'll will be making a whole chassis

Whats really dangerous is most of us are engineering geeks and have a geeky platform to work on so someday ya'll will be making a whole chassis