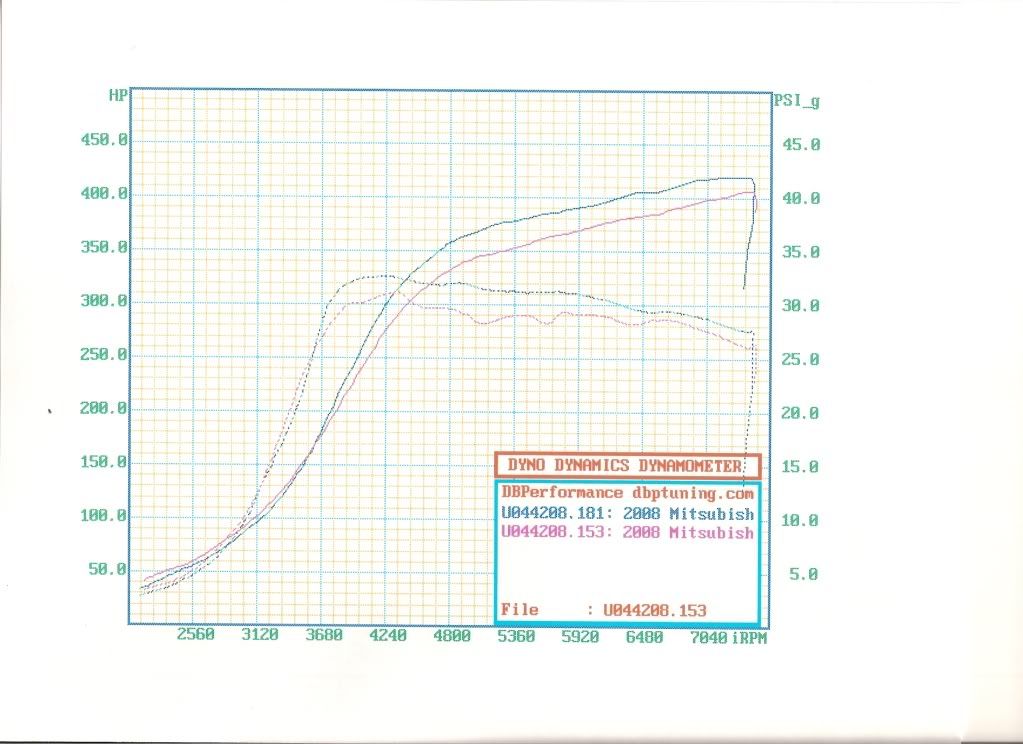

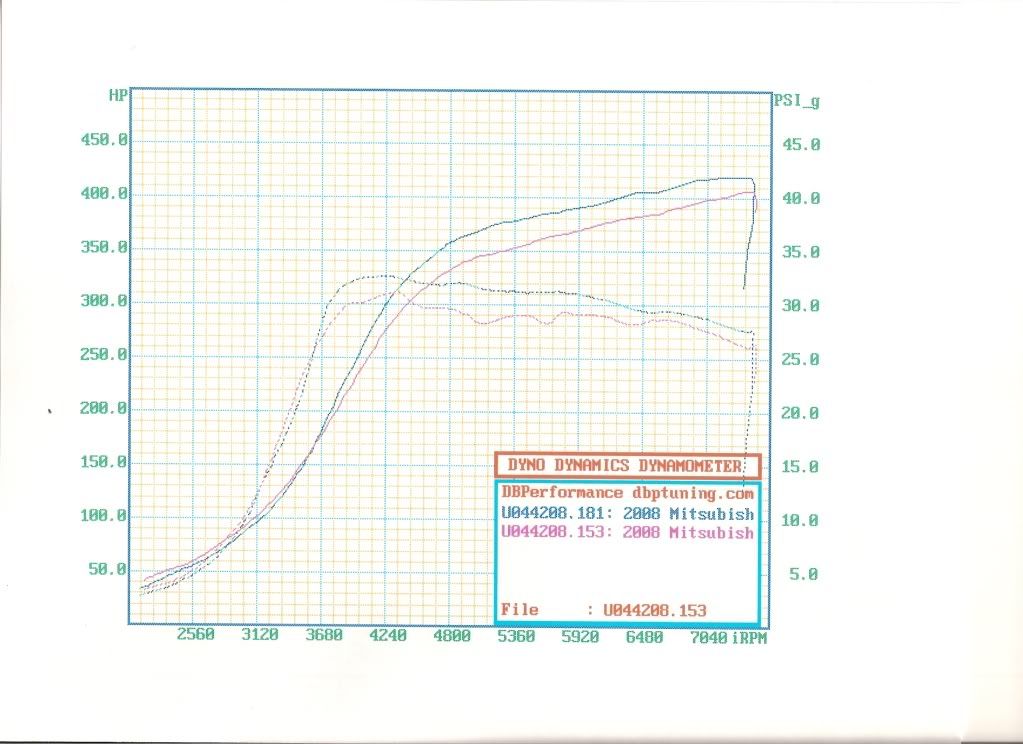

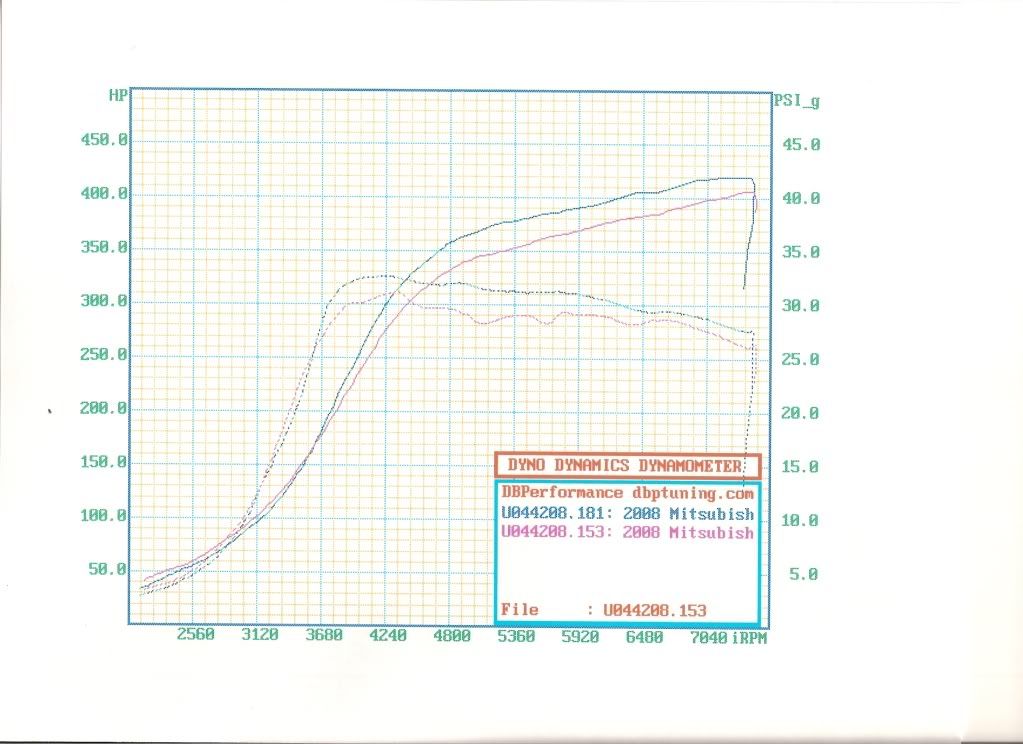

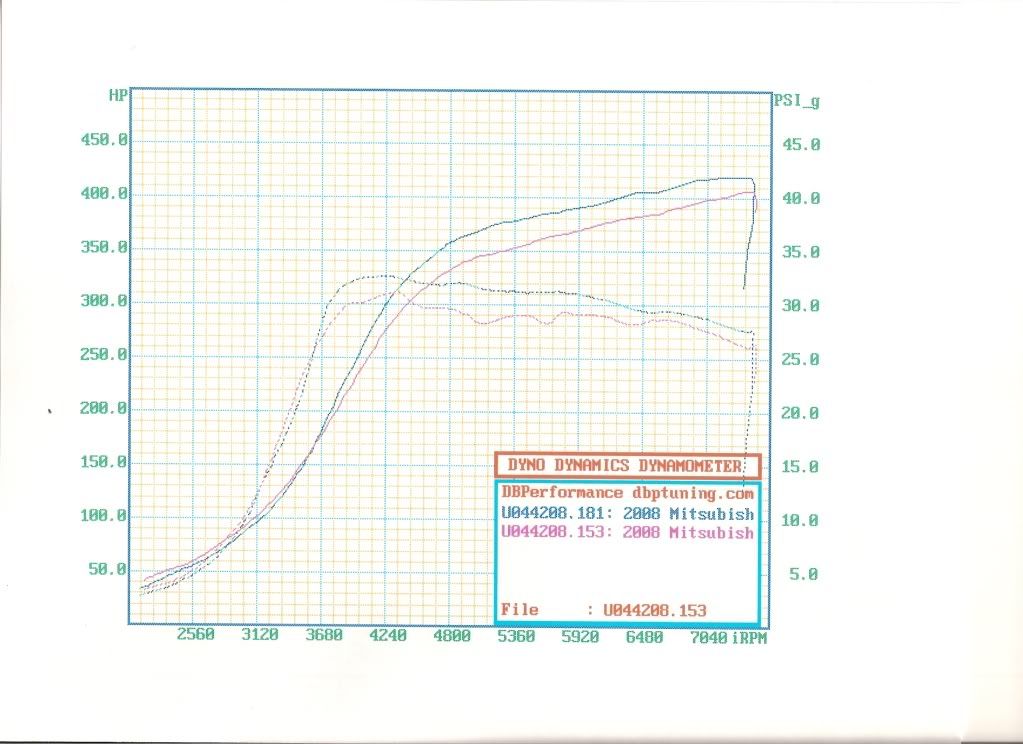

FP Black vs. BBK comparison results

#91

you know how to make sure it never cracks open prematurely? you pressurize the wg actuator slip the arm off then adjust the arm so its humanly impossible to slip it over unless you pressurize the wg and actuate the arm then you slip it on.. this way when it cracks open its barely cracking open at all.. you will feel the difference.

Spool wise, the black will still hit 30 psi on a 2.3L 93oct not sooner than 4100rpm...

Last edited by darwin_evo; Aug 19, 2010 at 12:48 AM.

#92

Former Sponsor

iTrader: (22)

You sir need to calm down and listen to others have to say. You have logs in front of you and others have logs. Setting the boost higher will have the effect i described before. If your target boost is 30psi your boost controller (whatever it is) will need to begin bleeding before boost reaches 30psi (o'wise you will have a higher spike), which will delay the spool compared to having it closed until 30psi (case when target boost is 40psi).

Spool wise, the black will still hit 30 psi on a 2.3L 93oct not sooner than 4100rpm...

Spool wise, the black will still hit 30 psi on a 2.3L 93oct not sooner than 4100rpm...

also on e85 you can get 35psi by:

and yes i know what youre thinking with the higher boost setting thing and yes it makes sense, but from my tests there are no changes. and as mentioned above it is probably just because the mbc is made good. with a cheaper mbc or bleeder valve system it would effect by a few psi no doubt.

Last edited by tscompusa2; Aug 19, 2010 at 02:51 AM.

#93

Evolved Member

iTrader: (125)

tscompusa, your conclusions are not correct. you need to stop opening your mouth. you dont know how to do good back to back and draw the correct conclusions. there are countless dyno graphs in the result sections of cars at two boost levels showing the torque rise is sharper at higher boost with no other changes.

there are no 30psi wastegate springs so lets not use that as an example. I will use my recently setup evo 1 as an example. it uses a holset actuator on the turbo and a quality hallman MBC. all quality boost controllers have a bleed hole.

On the bench testing the actuator with lots of preload the actuator starts to open at 20psi and is fully open at 30psi. On the car if there were no back pressure in the manifold the wastegate setup like this should hold about 24psi boost. On the car wastegate boost is only 15psi. cracking pressure on car is about 10psi.

This 9 psi difference comes from the exhaust manifold pressure. The back pressure pushes on the waste gate valve which effectively lower spring pressure about 9 psi in this example.

Now lets add manual boost controller. A manual boost controller does in affect bleed off boost pressure getting to the wastegate. it does this two ways. The bleed hole. This exists on all modern wastegates and can be heard leaking with any decent boost leak check. The second is the ball and spring. The ball and spring works like the wastegate. there is a range at which the spring operates. it has a cracking pressure and a full open pressure. if its adding 10 psi to boost curve then the full open pressure is 10 psi. the cracking pressure much less, maybe 6-7psi.

if you were to add boost controller to bench test you would see new cracking pressure at 30psi and full open at 40psi. on car cracking pressure is now 20psi with boost holding 25psi.

Torque curve and boost response is vastly different from cracking pressure 10psi and 20psi. Holding the wastegate valve on its seat for 10psi longer is huge. On my car car 10psi-16psi takes .2 seconds on wastegate pressure. with hallman set at 25psi it takes .1 second to go from 10psi to 20psi. If we use 16psi as our example here you can see 16psi is being reached far faster at higher boost level.

This is an exaggerated case of boost response increase. but the exact same thing happens raising boost from 30 to 40 psi. the change would be much smaller and harder to see.

there are no 30psi wastegate springs so lets not use that as an example. I will use my recently setup evo 1 as an example. it uses a holset actuator on the turbo and a quality hallman MBC. all quality boost controllers have a bleed hole.

On the bench testing the actuator with lots of preload the actuator starts to open at 20psi and is fully open at 30psi. On the car if there were no back pressure in the manifold the wastegate setup like this should hold about 24psi boost. On the car wastegate boost is only 15psi. cracking pressure on car is about 10psi.

This 9 psi difference comes from the exhaust manifold pressure. The back pressure pushes on the waste gate valve which effectively lower spring pressure about 9 psi in this example.

Now lets add manual boost controller. A manual boost controller does in affect bleed off boost pressure getting to the wastegate. it does this two ways. The bleed hole. This exists on all modern wastegates and can be heard leaking with any decent boost leak check. The second is the ball and spring. The ball and spring works like the wastegate. there is a range at which the spring operates. it has a cracking pressure and a full open pressure. if its adding 10 psi to boost curve then the full open pressure is 10 psi. the cracking pressure much less, maybe 6-7psi.

if you were to add boost controller to bench test you would see new cracking pressure at 30psi and full open at 40psi. on car cracking pressure is now 20psi with boost holding 25psi.

Torque curve and boost response is vastly different from cracking pressure 10psi and 20psi. Holding the wastegate valve on its seat for 10psi longer is huge. On my car car 10psi-16psi takes .2 seconds on wastegate pressure. with hallman set at 25psi it takes .1 second to go from 10psi to 20psi. If we use 16psi as our example here you can see 16psi is being reached far faster at higher boost level.

This is an exaggerated case of boost response increase. but the exact same thing happens raising boost from 30 to 40 psi. the change would be much smaller and harder to see.

Last edited by 94AWDcoupe; Aug 19, 2010 at 04:57 AM.

#94

On the bench testing the actuator with lots of preload the actuator starts to open at 20psi and is fully open at 30psi. On the car if there were no back pressure in the manifold the wastegate setup like this should hold about 24psi boost. On the car wastegate boost is only 15psi. cracking pressure on car is about 10psi.

This 9 psi difference comes from the exhaust manifold pressure. The back pressure pushes on the waste gate valve which effectively lower spring pressure about 9 psi in this example.

This 9 psi difference comes from the exhaust manifold pressure. The back pressure pushes on the waste gate valve which effectively lower spring pressure about 9 psi in this example.

#95

Former Sponsor

iTrader: (22)

tscompusa, your conclusions are not correct. you need to stop opening your mouth. you dont know how to do good back to back and draw the correct conclusions. there are countless dyno graphs in the result sections of cars at two boost levels showing the torque rise is sharper at higher boost with no other changes.

there are no 30psi wastegate springs so lets not use that as an example. I will use my recently setup evo 1 as an example. it uses a holset actuator on the turbo and a quality hallman MBC. all quality boost controllers have a bleed hole.

On the bench testing the actuator with lots of preload the actuator starts to open at 20psi and is fully open at 30psi. On the car if there were no back pressure in the manifold the wastegate setup like this should hold about 24psi boost. On the car wastegate boost is only 15psi. cracking pressure on car is about 10psi.

This 9 psi difference comes from the exhaust manifold pressure. The back pressure pushes on the waste gate valve which effectively lower spring pressure about 9 psi in this example.

Now lets add manual boost controller. A manual boost controller does in affect bleed off boost pressure getting to the wastegate. it does this two ways. The bleed hole. This exists on all modern wastegates and can be heard leaking with any decent boost leak check. The second is the ball and spring. The ball and spring works like the wastegate. there is a range at which the spring operates. it has a cracking pressure and a full open pressure. if its adding 10 psi to boost curve then the full open pressure is 10 psi. the cracking pressure much less, maybe 6-7psi.

if you were to add boost controller to bench test you would see new cracking pressure at 30psi and full open at 40psi. on car cracking pressure is now 20psi with boost holding 25psi.

Torque curve and boost response is vastly different from cracking pressure 10psi and 20psi. Holding the wastegate valve on its seat for 10psi longer is huge. On my car car 10psi-16psi takes .2 seconds on wastegate pressure. with hallman set at 25psi it takes .1 second to go from 10psi to 20psi. If we use 16psi as our example here you can see 16psi is being reached far faster at higher boost level.

This is an exaggerated case of boost response increase. but the exact same thing happens raising boost from 30 to 40 psi. the change would be much smaller and harder to see.

there are no 30psi wastegate springs so lets not use that as an example. I will use my recently setup evo 1 as an example. it uses a holset actuator on the turbo and a quality hallman MBC. all quality boost controllers have a bleed hole.

On the bench testing the actuator with lots of preload the actuator starts to open at 20psi and is fully open at 30psi. On the car if there were no back pressure in the manifold the wastegate setup like this should hold about 24psi boost. On the car wastegate boost is only 15psi. cracking pressure on car is about 10psi.

This 9 psi difference comes from the exhaust manifold pressure. The back pressure pushes on the waste gate valve which effectively lower spring pressure about 9 psi in this example.

Now lets add manual boost controller. A manual boost controller does in affect bleed off boost pressure getting to the wastegate. it does this two ways. The bleed hole. This exists on all modern wastegates and can be heard leaking with any decent boost leak check. The second is the ball and spring. The ball and spring works like the wastegate. there is a range at which the spring operates. it has a cracking pressure and a full open pressure. if its adding 10 psi to boost curve then the full open pressure is 10 psi. the cracking pressure much less, maybe 6-7psi.

if you were to add boost controller to bench test you would see new cracking pressure at 30psi and full open at 40psi. on car cracking pressure is now 20psi with boost holding 25psi.

Torque curve and boost response is vastly different from cracking pressure 10psi and 20psi. Holding the wastegate valve on its seat for 10psi longer is huge. On my car car 10psi-16psi takes .2 seconds on wastegate pressure. with hallman set at 25psi it takes .1 second to go from 10psi to 20psi. If we use 16psi as our example here you can see 16psi is being reached far faster at higher boost level.

This is an exaggerated case of boost response increase. but the exact same thing happens raising boost from 30 to 40 psi. the change would be much smaller and harder to see.

Ive actually seen less boost in areas running more boost.. wether thats a back pressure issue or not (fmic), i do recall seeing it.

And as you seen, I retracted some statements I made in my previous posts because they were down right rude.. and I apologize, its just I got so upset with your response.

and btw, yes i do know how to do back to back testing.. whats so hard about turning up the boost and then repeating

the same pull over at the same rpm level and then comparing the 2 logs? throw them in virtual dyno and even see the

boost plot + the torque curve. anyone can do it.

Last edited by tscompusa2; Aug 19, 2010 at 02:58 PM.

#96

Former Sponsor

iTrader: (22)

Jerry this part interests me - With the turbo sitting on my bench w/25psi wga installed, compressor in hand, the actuator starts to open at ~24psi and is almost all the way open by 27-29psi. I keep thinking once I get it on the car this is all going to change. Am I basically going to have to wait until I get the car running and do a bunch of trial/error runs to get the wastegate boost pressure I desire?

I read back a month ago or so if you run a dual external gated exhaust manifold with a black that separates the 2 twin scroll areas you can really control the boost even with the stock restrictive housing.

#97

Former Sponsor

iTrader: (22)

this shows approx 2psi diff..

now with this said.. theres to many variables on a road.. timing changes, AFR changes, Engine Temp changes, etc.. so many things can effect the spooling charactoristics from pull to pull.

I agree tho with running more boost there is an increase in boost sooner, and it makes perfect sense because things are staying shut 100% vs bleeding off to get ready to control boost.. so more boost = staying shut longer ....... lower boost = bleeding occurs sooner and the vehicle begins to vent gases earlier to control the boost level desired.

sorry about all the arguing guys.

now with this said.. theres to many variables on a road.. timing changes, AFR changes, Engine Temp changes, etc.. so many things can effect the spooling charactoristics from pull to pull.

I agree tho with running more boost there is an increase in boost sooner, and it makes perfect sense because things are staying shut 100% vs bleeding off to get ready to control boost.. so more boost = staying shut longer ....... lower boost = bleeding occurs sooner and the vehicle begins to vent gases earlier to control the boost level desired.

sorry about all the arguing guys.

#98

Evolved Member

iTrader: (9)

tscomp, i think this is what you and others are talking about...notice on the 30ish psi tune, it takes several hundred rpms extra to hit 30psi vs my 33psi tune. Same setup too.

Typically a tuner will slow spool near your target boost simply to avoid overshooting it and boost spikes... its the right thing to do

Typically a tuner will slow spool near your target boost simply to avoid overshooting it and boost spikes... its the right thing to do

#99

Former Sponsor

iTrader: (22)

tscomp, i think this is what you and others are talking about...notice on the 30ish psi tune, it takes several hundred rpms extra to hit 30psi vs my 33psi tune. Same setup too.

Typically a tuner will slow spool near your target boost simply to avoid overshooting it and boost spikes... its the right thing to do

Typically a tuner will slow spool near your target boost simply to avoid overshooting it and boost spikes... its the right thing to do

thats decent power on a bastard dyno.

#100

Evolved Member

iTrader: (9)

ya.. in this case i was wrong tho. i will admit when im wrong. 94AWD was right. If you run more boost it will keep things shut longer because it wont need to bleed to control as early. for example i want 40psi. the controller is not going to leak until like 38psi or so. If you want 33psi the controller will start to leak earlier to make sure you get that 33psi and not over. therefore youre not even close to bleeding air at 33psi when your target is 40 and vice versa.

thats decent power on a bastard dyno.

thats decent power on a bastard dyno.

#101

This example is definately wrong. A ball and spring boost controller does not simply add the amount of pressure to the WG spring pressure. An MBC that sets boost at 30psi will be 30psi on a 5psi actuator or a 15psi actuator or 25psi actuator provided the actuator is sufficient to hold the flapper closed against exhaust backpressure. It doesnt allow any pressure to go past the ball until the spring pressure is overcome. Then if the pressure is higher than the wg pressure then the boost will be set at that boost level. If it is lower it will open before the WG and not affect boost.

One other thing to realize is if it is the same the turbo will spool faster because the boost controller will hold all pressure from the WG actuator until the spring pressure is overcome. Also an EBC can be set to totally block all pressure from the WG until just before target boost is acheived keeping the turbo at full spool. If you open it too soon you will have slower spool, if you open it to late you will spike. Do it correctly and it will spool super fast. I leave it to spike a little since I run e85 and the little tq bump from the momentary boost spike is nice.

One other point to remember is that the bleed hole is AFTER the ball and spring so there is only bleed going on once the MBC is open. The purpose is not to raise boost by allowing air to bleed, its purpose is to prevent a wg from getting locked open because of air being trapped between the actuator and the now seated ball and spring. Thats why an MBC with no bleed hole will not hold boost properly up top and one with too large a bleed hole will not be consistent with boost control up top.

One other thing to realize is if it is the same the turbo will spool faster because the boost controller will hold all pressure from the WG actuator until the spring pressure is overcome. Also an EBC can be set to totally block all pressure from the WG until just before target boost is acheived keeping the turbo at full spool. If you open it too soon you will have slower spool, if you open it to late you will spike. Do it correctly and it will spool super fast. I leave it to spike a little since I run e85 and the little tq bump from the momentary boost spike is nice.

One other point to remember is that the bleed hole is AFTER the ball and spring so there is only bleed going on once the MBC is open. The purpose is not to raise boost by allowing air to bleed, its purpose is to prevent a wg from getting locked open because of air being trapped between the actuator and the now seated ball and spring. Thats why an MBC with no bleed hole will not hold boost properly up top and one with too large a bleed hole will not be consistent with boost control up top.

Now lets add manual boost controller. A manual boost controller does in affect bleed off boost pressure getting to the wastegate. it does this two ways. The bleed hole. This exists on all modern wastegates and can be heard leaking with any decent boost leak check. The second is the ball and spring. The ball and spring works like the wastegate. there is a range at which the spring operates. it has a cracking pressure and a full open pressure. if its adding 10 psi to boost curve then the full open pressure is 10 psi. the cracking pressure much less, maybe 6-7psi.

Thread

Thread Starter

Forum

Replies

Last Post

boostedwrx

Evo Engine / Turbo / Drivetrain

82

Jul 1, 2010 05:25 PM

boostedwrx

Northwest Region

10

May 26, 2010 04:09 PM

boostedwrx

Evo Dyno Tuning / Results

48

Jan 18, 2010 08:09 PM

GST Motorsports

Evo Dyno Tuning / Results

37

Dec 1, 2009 06:49 PM

boostedwrx

For Sale - Wheels / Tires

4

Jul 12, 2009 08:14 PM