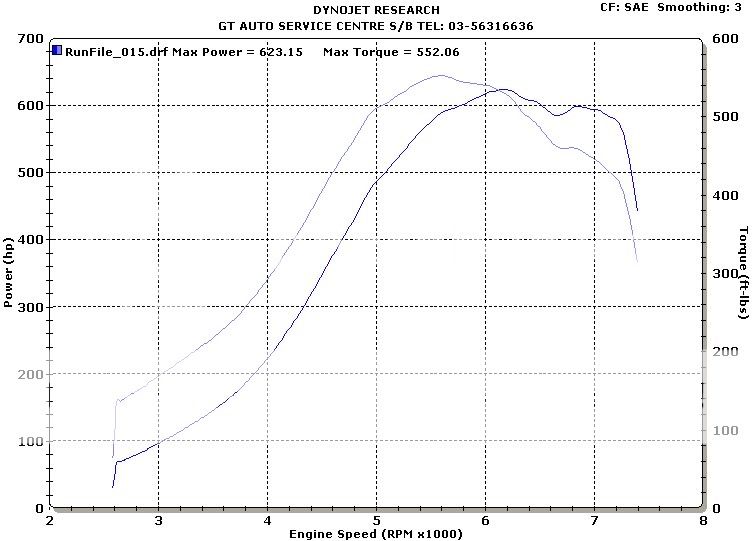

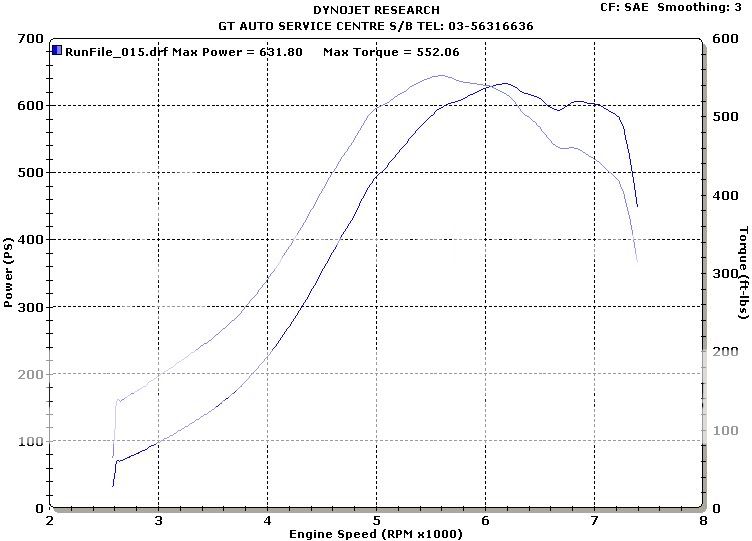

631 WHP/ 554 ft/ib WTQ, GT35R stroker!

#16

Evolving Member

Thread Starter

Well, you should see the new Cometic Phusion gaskets, it comes with 4 individual gas filled rings specially made and it works and looks like an O- ring to fit in between the gasket. I reckon its working that way already.

We don't have the capability to do o ringing here. not the tools or equipment anyway...

We don't have the capability to do o ringing here. not the tools or equipment anyway...

#18

Evolving Member

Thread Starter

We run up to 35 psi but the turbo showed very little power increase above that boost level. Similarly with my drag evo 3 as well. But it seems to be choking at the top end. Will run a 1 A/R turbine housing next to see if anything more is achievable...

#20

Former Sponsor

iTrader: (56)

Join Date: Sep 2004

Location: DFW, TX

Posts: 2,701

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by GTREVO

At extreme boost levels, when doing a dyno run or a quarter mile run the motor goes into misfiring mode and settles down after 2 min's or so at idle. At that very same time, the power level drops significantly. That is what valve float is. With the previous HKS valve springs, the problem is so prominent that anything above 32 psi will float the valves.

As for head lifting, there is no blown head gasket. Water from the overflow tank gets pushed out on boost at high boost levels and very little at low boost levels. When we disassembled the motor , the HKS metal head gasket showed no signs of leak or a blown syndrome. Head was slightly warped, had to re surface both the head and the block as well as trying out the new head gasket from Cometic to make it work.

As for head lifting, there is no blown head gasket. Water from the overflow tank gets pushed out on boost at high boost levels and very little at low boost levels. When we disassembled the motor , the HKS metal head gasket showed no signs of leak or a blown syndrome. Head was slightly warped, had to re surface both the head and the block as well as trying out the new head gasket from Cometic to make it work.

if your car is going into a misfire mode, obviously the power is going to cut. that does not mean the valves are floating. and boost should not effect the springs at all. the compression chamber pressures regardless of boost levels will push the valve closed, and when the valve is open but closing, you have a minimal pressure differential compared to the strength of the spring. maybe the HKS springs you had in there were tapping bad, and the noise from the tapping was pushing the engine into knock mode?

#23

EvoM Guru

iTrader: (6)

The chart looks a bit strange because due to the difference between the hp and torque scaling, the two curves cross just past 6000rpm as opposed to 5252.

The drop in the torque curve represents the limits of mechanical efficiency at that point, and there are several ways to address this if so desired. If big midrange torque is desired (and this motor definitely has it), it appears to be largely a non-issue.

The drop in the torque curve represents the limits of mechanical efficiency at that point, and there are several ways to address this if so desired. If big midrange torque is desired (and this motor definitely has it), it appears to be largely a non-issue.

#24

Evolved Member

iTrader: (4)

Join Date: Apr 2004

Location: Stafford, VA

Posts: 618

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by KevinD

just figure out why it falls off so bad past peak torque and it will be hard to beat.

Not to mention that he is moving to a 1 A/R to help out the situation.

#25

Evolved Member

iTrader: (21)

Join Date: Jun 2005

Location: chicago

Posts: 2,997

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by KevinD

although what your experiencing is most likely not valve float, that is still a very odd problem. valve float is when you run an engine to extremely high RPMs (WAAAAAY more then what your running the evo at), and the valve spring does not have enough time to fully close the valve. another condition it could happen is if you used super soft springs, or installed them improperly.

if your car is going into a misfire mode, obviously the power is going to cut. that does not mean the valves are floating. and boost should not effect the springs at all. the compression chamber pressures regardless of boost levels will push the valve closed, and when the valve is open but closing, you have a minimal pressure differential compared to the strength of the spring. maybe the HKS springs you had in there were tapping bad, and the noise from the tapping was pushing the engine into knock mode?

if your car is going into a misfire mode, obviously the power is going to cut. that does not mean the valves are floating. and boost should not effect the springs at all. the compression chamber pressures regardless of boost levels will push the valve closed, and when the valve is open but closing, you have a minimal pressure differential compared to the strength of the spring. maybe the HKS springs you had in there were tapping bad, and the noise from the tapping was pushing the engine into knock mode?

#26

Former Sponsor

iTrader: (56)

Join Date: Sep 2004

Location: DFW, TX

Posts: 2,701

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by scorke

^ It has nothing to do with enough time, it has to do with the valve spring not creating enough pressure to make the valve return to the seated position /moving towardst he seated position while the piston is cycling.

Scorke

Scorke

if you use a stiff spring, it will have the force to change the direction of the valve much quicker, thus returning it to the seat in considerably less time.

#27

Evolved Member

iTrader: (18)

Originally Posted by KevinD

it has everything to do with time. if you use a soft valve spring, it is weak, doesn't make enough force to counter the inertia of the valve and will take considerable longer to return the valve to its seat. if you revv the engine slowly, it will be able to return it. as you revv the engine faster, that valve spring doesn't have the force ( f = m*a where the m is the valve mass, and the f is the spring force)to achieve the high accelerations to return the spring in a reduced cycle time due to the higher revvs.

if you use a stiff spring, it will have the force to change the direction of the valve much quicker, thus returning it to the seat in considerably less time.

if you use a stiff spring, it will have the force to change the direction of the valve much quicker, thus returning it to the seat in considerably less time.

Originally Posted by KevinD/scorke

if you use a soft valve spring, it is weak, doesn't make enough force to counter the inertia of the valve and will take considerable longer to return the valve to its seat.

#29

Former Sponsor

iTrader: (56)

Join Date: Sep 2004

Location: DFW, TX

Posts: 2,701

Likes: 0

Received 0 Likes

on

0 Posts

scorke, the force the spring has is entirely meaningless without knowing the time the valve has to close, and the accelerations required by that valve to close in the given time at a given rpm. obviously the higher the rpm, the less time, and thus higher accelerations. if you have high acceleration requirements, you need more force, i.e. higher spring rate. notice again, that for a given spring rate, TIME is what determines if you are going to have valve float.

#30

Evolved Member

iTrader: (18)

I dunno maybe your right, I was under the impression valve spring pressure/the ramp rate of the cam/the duration of the cam was what you would use to see if you have valve float, time just simplifies that....The time that it takes for the valve to go back to the seated position is determined by the lift of the cam, the ramp rate of the cam and the pressure/force exerted by the spring

Scorke

Scorke

You almost max up the GT35R !!

You almost max up the GT35R !!