Attention All Aluminum Rod Engine Owners....

#18

Evolving Member

Thread Starter

iTrader: (14)

Join Date: Aug 2007

Location: New York

Posts: 389

Likes: 0

Received 0 Likes

on

0 Posts

We have had trouble trying to make them fit. It barely fit when I did 162s with the 94mm and the 156s and 94mm were also pretty close. Just getting the I beams to fit requires clearancing. However if the GRP is smaller in the beam than the R&R they might fit pretty tight as a 150 but still make it.

Its not that we didnt want to, we just couldnt see a way to make it work how we wanted.

Its not that we didnt want to, we just couldnt see a way to make it work how we wanted.

). I tend to not get scared off from opinions that have no actual factual data, and just a hunch in something not working properly/efefctively. I guess its all in what you're willing to try and trust. In the end, I could be an idiot for choosing the combo I went with, or in the end I could be the reason people follow those steps. Either way... it's all fine by me, money well spent in the pursuit of a dream. Time will tell if it works out for my application.

). I tend to not get scared off from opinions that have no actual factual data, and just a hunch in something not working properly/efefctively. I guess its all in what you're willing to try and trust. In the end, I could be an idiot for choosing the combo I went with, or in the end I could be the reason people follow those steps. Either way... it's all fine by me, money well spent in the pursuit of a dream. Time will tell if it works out for my application.This is kinda why I started this thread... I think it'll be very useful in the future. It'll definitely close some mouths and open some eyes if you know what I mean.

#20

Evolved Member

iTrader: (30)

Stock radiator from the factory

On the 2.2 we had to bore the oil galley, sleeve the oil galley, then grind through parts of the oil galley to make the 162mm and 94mm crank work. The 156 doesnt have as much dwell time so the big end (which is ALOT larger than stock) is not up against the edge of the block and it seems to work alot better.

I would presume a 150mm aluminum and a good non coreshifted block might work like the 156 and the 156 like the 162. I didnt like the 900 additional I spent on machine work to make the 2.2 work though looking back. I want to make a smaller beam aluminum rod that might only be good to 1100whp instead of the 1400whp that the standard R&R is.

Looking at Spyros thread on the solidworks it looks like you could do it and not sacrifice much and not have to go to a Ti MMC style rod. I am assuming those are probably per rod what I pay for 2 sets of R&Rs.

On the 2.2 we had to bore the oil galley, sleeve the oil galley, then grind through parts of the oil galley to make the 162mm and 94mm crank work. The 156 doesnt have as much dwell time so the big end (which is ALOT larger than stock) is not up against the edge of the block and it seems to work alot better.

I would presume a 150mm aluminum and a good non coreshifted block might work like the 156 and the 156 like the 162. I didnt like the 900 additional I spent on machine work to make the 2.2 work though looking back. I want to make a smaller beam aluminum rod that might only be good to 1100whp instead of the 1400whp that the standard R&R is.

Looking at Spyros thread on the solidworks it looks like you could do it and not sacrifice much and not have to go to a Ti MMC style rod. I am assuming those are probably per rod what I pay for 2 sets of R&Rs.

#22

Former Sponsor

iTrader: (20)

Join Date: Oct 2005

Location: Denver, CO

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

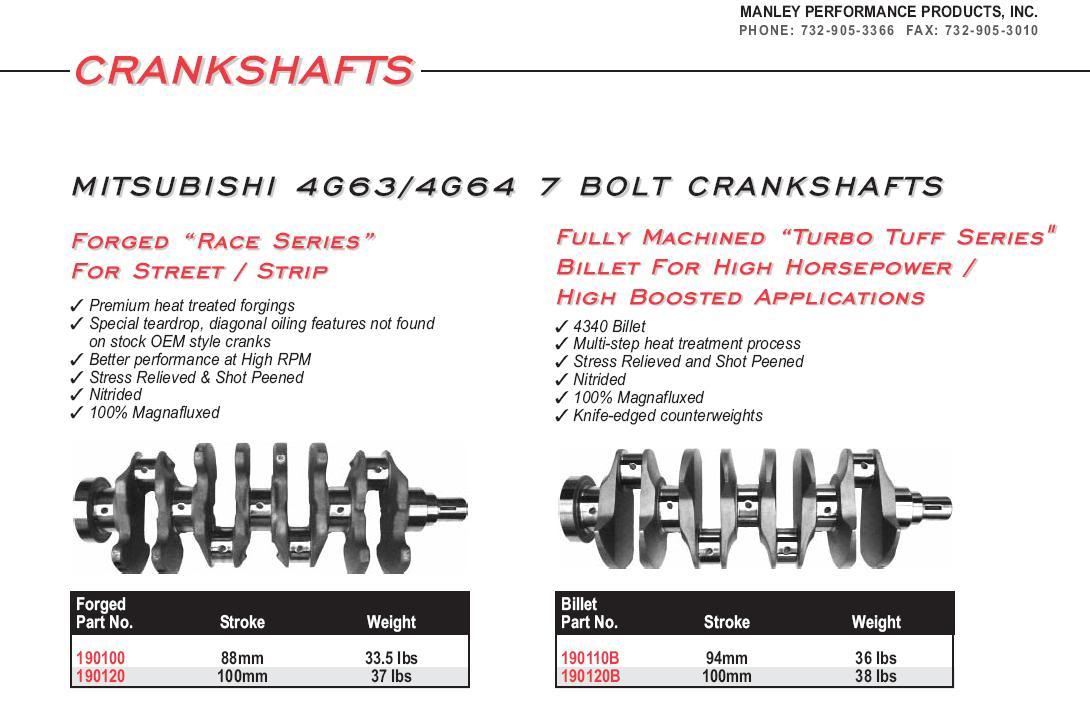

Manley crank weighs 38lbs

Winberg crank weighs 26lbs

Bust out your crayons and do some math and get back to us after you re-read your mis-leading post (which is about 99.8% of your posts are).

Last edited by DynoDude55; Jun 24, 2010 at 07:57 AM.

#23

Evolving Member

Thread Starter

iTrader: (14)

Join Date: Aug 2007

Location: New York

Posts: 389

Likes: 0

Received 0 Likes

on

0 Posts

The Manley crank you're talking about: (33lbs not 38lbs)

http://www.extremepsi.com/store/cust...0VIII%20&%20IX

The 100mm Manley crank I'm using in my 4G64 2.4 Aluminum 156mm Long Rod 10.5:1cr build

http://i47.photobucket.com/albums/f1...ods/photo1.jpg

http://i47.photobucket.com/albums/f1...Mods/photo.jpg

Last edited by MagicManRed; Jun 13, 2011 at 06:05 PM. Reason: typo

#27

Evolving Member

iTrader: (18)

It all depends on your setup. I did a study on this using MATLAB programming. (negative tensile force is compression)

Even if two cars are making the exact same torque at the same rpm with the same fuel it really depends on the setup. For example a 4g63 making 500 ft-lbs on nitrous alone would have to be timed MUCH closer to TDC (360 degrees on graph) while a low compression 4g63 with boost could be closer to 25 or so.

In order for both motors to make 500 ft-lbs, the total area inside the compressional force plot would have to match. The difference is the nitrous motor would have a smaller window but would spike higher, and the boosted motor would have a bigger window but wouldn't spike near as high. They make the same torque but the max compression force on the boosted motor isn't as high.

Using this principle, pretty much any setup that is tuned for 25 or more degrees of timing (without knock) is going to last quite some time. Not only is the max compression force lower but the shock isn't as bad either; it's progressive.

Even if two cars are making the exact same torque at the same rpm with the same fuel it really depends on the setup. For example a 4g63 making 500 ft-lbs on nitrous alone would have to be timed MUCH closer to TDC (360 degrees on graph) while a low compression 4g63 with boost could be closer to 25 or so.

In order for both motors to make 500 ft-lbs, the total area inside the compressional force plot would have to match. The difference is the nitrous motor would have a smaller window but would spike higher, and the boosted motor would have a bigger window but wouldn't spike near as high. They make the same torque but the max compression force on the boosted motor isn't as high.

Using this principle, pretty much any setup that is tuned for 25 or more degrees of timing (without knock) is going to last quite some time. Not only is the max compression force lower but the shock isn't as bad either; it's progressive.

#28

Evolved Member

iTrader: (30)

It all depends on your setup.

Using this principle, pretty much any setup that is tuned for 25 or more degrees of timing (without knock) is going to last quite some time. Not only is the max compression force lower but the shock isn't as bad either; it's progressive.

Using this principle, pretty much any setup that is tuned for 25 or more degrees of timing (without knock) is going to last quite some time. Not only is the max compression force lower but the shock isn't as bad either; it's progressive.

25* is past MBT in my experience and therefore has exponentially increased cylinder pressure (6-7* past) according to my understanding, but you are saying has reduced crankshaft forces?

I dont understand the finer points of the engineering to fully grasp it, but is it because forces are equalised better between cylinders?

thanks

aaron

#29

Evolving Member

Thread Starter

iTrader: (14)

Join Date: Aug 2007

Location: New York

Posts: 389

Likes: 0

Received 0 Likes

on

0 Posts

I was talking about your crankshaft. It weighs 38lbs according to Manley's catalog.

http://i55.photobucket.com/albums/g1...ley_cranks.jpg

http://i55.photobucket.com/albums/g1...ley_cranks.jpg

https://secure.buschurracing.com/cat...f097749a828af7

Only 5lbs heavier than the Winberg, and Manley piece of mind. It's the revised version of what you thought was mine

#30

Evolving Member

iTrader: (18)

This intrigues me.

25* is past MBT in my experience and therefore has exponentially increased cylinder pressure (6-7* past) according to my understanding, but you are saying has reduced crankshaft forces?

I dont understand the finer points of the engineering to fully grasp it, but is it because forces are equalised better between cylinders?

thanks

aaron

25* is past MBT in my experience and therefore has exponentially increased cylinder pressure (6-7* past) according to my understanding, but you are saying has reduced crankshaft forces?

I dont understand the finer points of the engineering to fully grasp it, but is it because forces are equalised better between cylinders?

thanks

aaron