Having trouble removing rear hub

#1

Having trouble removing rear hub

OK guys, I have to replace the rear hub on an 04 EVO, pretty sure that everything that needs to be removed is apart right now. The caliper, rotor, axle nut, 4 studs holding the hub from behind the knuckle and one nut removed that looks like it holds part of the parking brake assembly. I have a slide hammer and the attachment fixed onto 3 studs ready to slam it off.

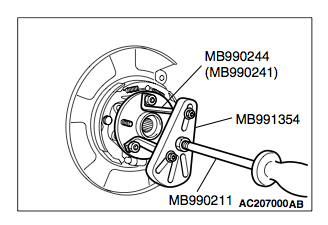

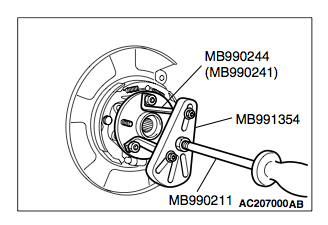

As per the manual is does not say anything about removing the parking brake assembly and just shows this diagram. It also mentions if it is seized to pull the knuckle and do it on a bench vise. how hard is it to actually remove it? I have pulled the axels up front when I did the clutch and they popped right out with a 10lb slide hammer. I gave it a good tug and got nothing. any help would be greatly appreciated. thanks guys

As per the manual is does not say anything about removing the parking brake assembly and just shows this diagram. It also mentions if it is seized to pull the knuckle and do it on a bench vise. how hard is it to actually remove it? I have pulled the axels up front when I did the clutch and they popped right out with a 10lb slide hammer. I gave it a good tug and got nothing. any help would be greatly appreciated. thanks guys

Last edited by Jersey Dino; Feb 19, 2010 at 12:20 PM.

#2

problem solved. I found a tool from a local autozone that works just like the above mitsubishi one. Anyway, it took quite a few good solid yanks on the slide hammer. but after that it popped right off. I did not take pictures along the way as I was pressed for time. I will try to do a formal write up later on but for anyone who needs to perform this job here are a few tips.

remove the wheel, caliper, rotor,, and axle nut.

from behind the hub, remove 4 14m studs holding the hub to the knuckle.

after this is done get the slide hammer out and pop the hub off.

when reinstalling the hub take you time and put the studs back in from behind to help you line up everything. It can only go together one way but for whatever reason this took a few attempts.

Also be careful with the ABS sensor/teeth on the axel.

Start to finger tighten each one in a criss cross pattern to help insure that the others line up properly. Torque the 4 14mm to 53+/- 5 lb ft

hit the axel nut with an air gun if you have one and reassemble the rest.

Cheers

remove the wheel, caliper, rotor,, and axle nut.

from behind the hub, remove 4 14m studs holding the hub to the knuckle.

after this is done get the slide hammer out and pop the hub off.

when reinstalling the hub take you time and put the studs back in from behind to help you line up everything. It can only go together one way but for whatever reason this took a few attempts.

Also be careful with the ABS sensor/teeth on the axel.

Start to finger tighten each one in a criss cross pattern to help insure that the others line up properly. Torque the 4 14mm to 53+/- 5 lb ft

hit the axel nut with an air gun if you have one and reassemble the rest.

Cheers

#3

Evolved Member

iTrader: (68)

I can't believe that the 4 14mm nuts on the back of the hub are only 53+/- ft lb.

I just took mine off yesterday and I swear they were at least 530 ft lb.

Thanks for the info though because I was stuck after getting those nuts out. I'll have to try out the slide hammer cuase I think my hub is near welded on.

I just took mine off yesterday and I swear they were at least 530 ft lb.

Thanks for the info though because I was stuck after getting those nuts out. I'll have to try out the slide hammer cuase I think my hub is near welded on.

#6

Evolved Member

iTrader: (8)

Join Date: Sep 2007

Location: Baltimore, MD

Posts: 1,019

Likes: 0

Received 0 Likes

on

0 Posts

i didnt want to have to take all that apart but i tried for prob 1.5 hrs with various methods and chemicals but nothing was working. the way i did it was a total piece of cake

edit: i think my problem was that when i was trying to hammer it out from the front and use the axle tool what was actually happening to mine was i was pulling the bearing out from the bearing shield, maybe wrong use of terms here. but all i was getting was more play in the hub and no signs of any gap being formed where the hub connects/bolts to the other assembly.

Last edited by Oki Panoki; Apr 26, 2010 at 08:44 AM.

Trending Topics

#10

Evolved Member

iTrader: (41)

After reading some recommendations on here I picked up 4 new Timken wheel bearing to replace on my car. Unfortunately to my surprise the front wheel bearings come as an assembly with the hub yet the rears are just the bearing. Therefore I need to separate the hub from the bearing assembly for the rears.

I am familiar with removing the wheel bearing assembly from the knuckle as I did it recently to install longer studs in the rear. However, I am not really sure the best way to separate the hub from the bearing.

I have a press so pressing it back in shouldnt be too difficult if I just go slowly. However Im not sure if I can somehow rig it up to press the hub out in the first place. So what is the best way to separate the hub? Should I rent the slide hammer and pull it out or use the tool that presses on the axle? I dont want to warb the hub obviously so that makes me a little nervous. And if I were to pull it out Im guessing I would need to keep the 4 bolts that attach the bearing tightened then pull out the hub and then undo those bolts and press out the bearing?

This is my daily driver so I need to make sure Im not going to f**k it up when trying to remove the hub or else I'll be stranded. Any further instruction would be greatly appreciated. Thanks in advance!

I am familiar with removing the wheel bearing assembly from the knuckle as I did it recently to install longer studs in the rear. However, I am not really sure the best way to separate the hub from the bearing.

I have a press so pressing it back in shouldnt be too difficult if I just go slowly. However Im not sure if I can somehow rig it up to press the hub out in the first place. So what is the best way to separate the hub? Should I rent the slide hammer and pull it out or use the tool that presses on the axle? I dont want to warb the hub obviously so that makes me a little nervous. And if I were to pull it out Im guessing I would need to keep the 4 bolts that attach the bearing tightened then pull out the hub and then undo those bolts and press out the bearing?

This is my daily driver so I need to make sure Im not going to f**k it up when trying to remove the hub or else I'll be stranded. Any further instruction would be greatly appreciated. Thanks in advance!

#11

EvoM Guru

iTrader: (1)

You can't press the hub out from the back side?

#12

Evolved Member

iTrader: (41)

Im not sure how I would physically set it up in my press in order to get it separated from the bearing...if you take a look at the bearing and hub assembly here Im talking about: http://www.streettunedmotorsports.co...el_bearing.htm may see what

With the wheel studs facing downward its almost as if I would need to somehow suspend the bearing assembly in the air so there is room for the actual hub to separate downward. Without suspending it in the air there is no room for the two pieces to separate. This is what leads me to believe it must be pulled out somehow. The simple solution is to just pick up an OEM set and return my Timken rear wheel bearings. But if its just going to require a little extra work I'd love to make do with what I have. Just would like some insight as to the proper way to separate the two before I dig in and end up stranding myself...

With the wheel studs facing downward its almost as if I would need to somehow suspend the bearing assembly in the air so there is room for the actual hub to separate downward. Without suspending it in the air there is no room for the two pieces to separate. This is what leads me to believe it must be pulled out somehow. The simple solution is to just pick up an OEM set and return my Timken rear wheel bearings. But if its just going to require a little extra work I'd love to make do with what I have. Just would like some insight as to the proper way to separate the two before I dig in and end up stranding myself...

#13

Evolved Member

iTrader: (41)

I decided to test my luck yesterday and ended up successful but not without a few hurdles to get past in the process. I started with a slide hammer to try and pull the hub free from the bearing. After a couple blows with the slide hammer I got the hub out but the bearing actually fell apart and left the inner race still attached to the hub.

So in order to remove the inner race from the hub I picked up one of these: http://www.harborfreight.com/large-b...ator-3979.html

That allowed me to suspend the hub in the air and use my press to pop it right off. I then used one of these to pul the hub to my new bearing http://www.harborfreight.com/fwd-fro...ers-66829.html

Feeling accomplished and confident I decided to attack the other side. I assumed the inner race would stay attached again so I just removed the whole bearing assembly in one piece installed the bearing separator suspended it in my press and proceeded to press it out. Out came the hub but the inner race was still attached. No big deal just reattach the bearing separator and tried again. Unfortunately when I started pressing the bearing separator started bending under the pressure. Crap...so I sprayed penetrating oil on the hub hoping itll start to work its way under there and I went back out to HF to pick up a new bearing separator. Got back home sprayed more penetrating oil hit the inner race with a torch for a few minuted then hit it with an air hammer hoping to try and shock it and break the seize. Then moment of truth, put the new bearing separator back on it and back to the press I went. After a couple cranks on my press and I heard a loud bang and I knew it finally broke free!

So at the end of the day I made it all work and everything is back together and all is well. I didnt snap any photos but wanted to try and help document what I did to help remove the hub from the bearing. I cant comment on the longevity of the Timken bearings yet but am told its a quality piece. So if you are looking to save some money without sacrificing quality this isnt a bad option. Personally Im not sure if it was worth the extra effort and had I known it wasnt a complete assembly when I bought them I would not have gone this route.

So in order to remove the inner race from the hub I picked up one of these: http://www.harborfreight.com/large-b...ator-3979.html

That allowed me to suspend the hub in the air and use my press to pop it right off. I then used one of these to pul the hub to my new bearing http://www.harborfreight.com/fwd-fro...ers-66829.html

Feeling accomplished and confident I decided to attack the other side. I assumed the inner race would stay attached again so I just removed the whole bearing assembly in one piece installed the bearing separator suspended it in my press and proceeded to press it out. Out came the hub but the inner race was still attached. No big deal just reattach the bearing separator and tried again. Unfortunately when I started pressing the bearing separator started bending under the pressure. Crap...so I sprayed penetrating oil on the hub hoping itll start to work its way under there and I went back out to HF to pick up a new bearing separator. Got back home sprayed more penetrating oil hit the inner race with a torch for a few minuted then hit it with an air hammer hoping to try and shock it and break the seize. Then moment of truth, put the new bearing separator back on it and back to the press I went. After a couple cranks on my press and I heard a loud bang and I knew it finally broke free!

So at the end of the day I made it all work and everything is back together and all is well. I didnt snap any photos but wanted to try and help document what I did to help remove the hub from the bearing. I cant comment on the longevity of the Timken bearings yet but am told its a quality piece. So if you are looking to save some money without sacrificing quality this isnt a bad option. Personally Im not sure if it was worth the extra effort and had I known it wasnt a complete assembly when I bought them I would not have gone this route.

#14

EvoM Guru

iTrader: (1)

You also could have just cut the inner race off with a cut off wheel. You just make one cut. It relieves the interference fit, and it slides ride off..

What you did with the bearing separator I was going to suggest you do with press plates, just put them under the ears of hub (where the bolts go through).

What you did with the bearing separator I was going to suggest you do with press plates, just put them under the ears of hub (where the bolts go through).

Last edited by letsgetthisdone; Feb 9, 2015 at 09:06 AM.

#15

Evolved Member

iTrader: (41)

Haha actually I lied in my story. When I first bent the tool I pulled out the cut off wheel and started going at it thinking just that. Then I looked at the clock and said f this lemme run back to HF and get a replacement before they close.

But yeah a cutoff wheel would have worked for sure granted I put on a 3" wheel but it was too big so I probably would have needed to bust out the dremel to get close to the hub without cutting that as well. But yeah figured I could just get really close than smack it with a sledge or something to crack it and it would just slip right off. So yeah that was my fall back plan.

As for the press plates to the ears of the hub, technically that could have worked. However in my case the bearing split on both sides and left the inner race still attached so I would have been in the same situation.

But yeah a cutoff wheel would have worked for sure granted I put on a 3" wheel but it was too big so I probably would have needed to bust out the dremel to get close to the hub without cutting that as well. But yeah figured I could just get really close than smack it with a sledge or something to crack it and it would just slip right off. So yeah that was my fall back plan.

As for the press plates to the ears of the hub, technically that could have worked. However in my case the bearing split on both sides and left the inner race still attached so I would have been in the same situation.

Thread

Thread Starter

Forum

Replies

Last Post

allday10sec

Evo How Tos / Installations

35

May 4, 2017 08:51 AM

tim85851

Evo How Tos / Installations

1

Apr 8, 2015 05:23 PM

vtluu

Evo How To Requests / Questions / Tips

25

Mar 31, 2013 02:39 AM