for anyone that has crankcase pressure issues

#288

Evolved Member

iTrader: (19)

tcomp- Nice setup. I know you really wanted to get the issue taken care of, and if this doesn't do it, then I vote that the car is haunted

On another note, I had a problem with the car this morning having excessive smoke and weird smell, I had no idea what was going on. It got to 15 degrees here in Pittsburgh this morning so it was extremely cold. Turned out my catch lines were like yours, with a slightly uphill route, and some of the condensate stayed in the line and froze in the dip. This led to pressure increases and the smoke... I have since shortened both lines significantly, relocated the can and routed the lines close to the motor as to keep them as hot as possible for as long as possible.

Weird problem indeed, I couldn't believe it when I ran compressed air through the line and got white **** everywhere... Watch out for the cold weather for those of us who are running VTA catch can setups.

On another note, I had a problem with the car this morning having excessive smoke and weird smell, I had no idea what was going on. It got to 15 degrees here in Pittsburgh this morning so it was extremely cold. Turned out my catch lines were like yours, with a slightly uphill route, and some of the condensate stayed in the line and froze in the dip. This led to pressure increases and the smoke... I have since shortened both lines significantly, relocated the can and routed the lines close to the motor as to keep them as hot as possible for as long as possible.

Weird problem indeed, I couldn't believe it when I ran compressed air through the line and got white **** everywhere... Watch out for the cold weather for those of us who are running VTA catch can setups.

#289

Evolved Member

iTrader: (33)

tcomp- Nice setup. I know you really wanted to get the issue taken care of, and if this doesn't do it, then I vote that the car is haunted

On another note, I had a problem with the car this morning having excessive smoke and weird smell, I had no idea what was going on. It got to 15 degrees here in Pittsburgh this morning so it was extremely cold. Turned out my catch lines were like yours, with a slightly uphill route, and some of the condensate stayed in the line and froze in the dip. This led to pressure increases and the smoke... I have since shortened both lines significantly, relocated the can and routed the lines close to the motor as to keep them as hot as possible for as long as possible.

Weird problem indeed, I couldn't believe it when I ran compressed air through the line and got white **** everywhere... Watch out for the cold weather for those of us who are running VTA catch can setups.

On another note, I had a problem with the car this morning having excessive smoke and weird smell, I had no idea what was going on. It got to 15 degrees here in Pittsburgh this morning so it was extremely cold. Turned out my catch lines were like yours, with a slightly uphill route, and some of the condensate stayed in the line and froze in the dip. This led to pressure increases and the smoke... I have since shortened both lines significantly, relocated the can and routed the lines close to the motor as to keep them as hot as possible for as long as possible.

Weird problem indeed, I couldn't believe it when I ran compressed air through the line and got white **** everywhere... Watch out for the cold weather for those of us who are running VTA catch can setups.

#290

Evolved Member

iTrader: (19)

Totally agreed. Even the liquid in the catch was over 50% water. Not something I want back in the crank case. I am expecting the lab results from the oil analysis of running without a PCV valve. We can compare those to ones with a PCV and get a definitive answer as to wether or not it will cause that big of a problem.

Results to follow...

Results to follow...

#293

Totally agreed. Even the liquid in the catch was over 50% water. Not something I want back in the crank case. I am expecting the lab results from the oil analysis of running without a PCV valve. We can compare those to ones with a PCV and get a definitive answer as to wether or not it will cause that big of a problem.

Results to follow...

Results to follow...

mines a sealed setup 100%. my car doesn't see cold weather tho, it stays in garage. I do take it out occasionally in the cold, but its in garage all winter.

I run e85 and heard e85 creates even more water in the catch can so i pitty whoever is running e85 and draining back to block.

Must of been so much water in your lines that it froze with the oil cause oil wont freeze until like -20 to -30f

#294

then i used MORSE ( 1/2"-14 NPT ) TAPERED THREAD PIPE TAP to thread it.

then finally teflon taped the fitting and screwed it on. Stainless Heater Hose Fitting 1/2" NPT 5/8" Hose 1001 found on ebay http://cgi.ebay.com/ebaymotors/ws/eB...#ht_1282wt_939

#295

Evolved Member

iTrader: (35)

On another note, I had a problem with the car this morning having excessive smoke and weird smell, I had no idea what was going on. It got to 15 degrees here in Pittsburgh this morning so it was extremely cold. Turned out my catch lines were like yours, with a slightly uphill route, and some of the condensate stayed in the line and froze in the dip. This led to pressure increases and the smoke... I have since shortened both lines significantly, relocated the can and routed the lines close to the motor as to keep them as hot as possible for as long as possible.

Weird problem indeed, I couldn't believe it when I ran compressed air through the line and got white **** everywhere... Watch out for the cold weather for those of us who are running VTA catch can setups.

Weird problem indeed, I couldn't believe it when I ran compressed air through the line and got white **** everywhere... Watch out for the cold weather for those of us who are running VTA catch can setups.

#296

Evolved Member

iTrader: (19)

Time will tell...

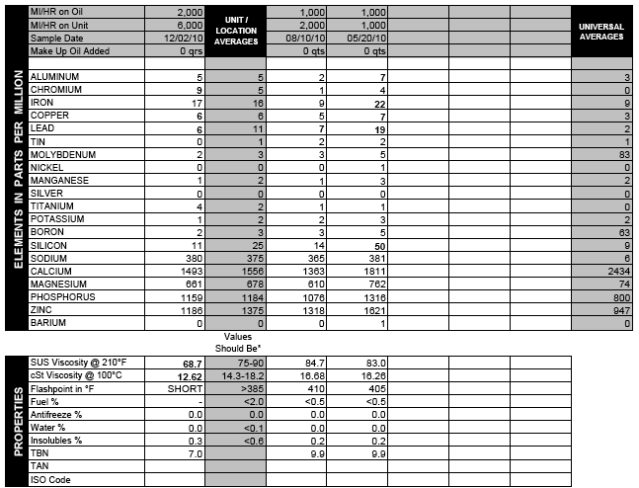

Oh, here is the oil analysis of the last run. Around 1,000 of those miles were with the PCV removed and running the VTA catch can.

#297

Evolved Member

iTrader: (25)

I didn't read all the posts, but can give some feedback for relieving block pressure under boost. Some of my old buddies racing large turbo'd mustangs would run a dedicated belt driven vacuum pump to relieve crankcase pressure.

I had some buddies with N/A cars use the Bernoulli effect within the exhaust immediately after the header collector to pull vacuum on the block under WOT. I have read that some use it on turbo cars with good success, but not SMOG legal.

http://www.moroso.com/catalog/catego...?catcode=13023

The good thing about the EVO is that we have a vacuum pump onboard called a turbocharger. Keep the PCV to the intake manifold because it helps to evacuate the block under off boost situations.

Here is what I have done on several project cars. Run the block vents to a sealed catch can. The catch can is also hooked to the turbo inlet so that it can pull vacuum on the can during boost. Run a one way (out only) valve on the bottom of the catch can and have it return to the oil pan. Under boost the can will pull vacuum from the turbo inlet and help evacuate the block, but won't pull oil from the pan due to the one-way valve. Off boost the one way drain valve will open and allow oil to freely drain to the pan.

Oil cannot take turns like air so baffling within the catchcan will be important to separate air from oil.

I ran a similar setup on the twinturbo ZR1 and the can would register ~2in-mg vacuum when the car was ~7psi of boost. Not as much vacuum as you would like, but at least it wasn't positive pressure.

The theory is no different than stock except you integrate the catch can so the turbo doesn't suck oil. Imagine that, Mitsubishi came to a similar conclusion. You could combine this with a Bernoulli effect on the downpipe to obtain even more sucking power on the catchcan.

I had some buddies with N/A cars use the Bernoulli effect within the exhaust immediately after the header collector to pull vacuum on the block under WOT. I have read that some use it on turbo cars with good success, but not SMOG legal.

http://www.moroso.com/catalog/catego...?catcode=13023

The good thing about the EVO is that we have a vacuum pump onboard called a turbocharger. Keep the PCV to the intake manifold because it helps to evacuate the block under off boost situations.

Here is what I have done on several project cars. Run the block vents to a sealed catch can. The catch can is also hooked to the turbo inlet so that it can pull vacuum on the can during boost. Run a one way (out only) valve on the bottom of the catch can and have it return to the oil pan. Under boost the can will pull vacuum from the turbo inlet and help evacuate the block, but won't pull oil from the pan due to the one-way valve. Off boost the one way drain valve will open and allow oil to freely drain to the pan.

Oil cannot take turns like air so baffling within the catchcan will be important to separate air from oil.

I ran a similar setup on the twinturbo ZR1 and the can would register ~2in-mg vacuum when the car was ~7psi of boost. Not as much vacuum as you would like, but at least it wasn't positive pressure.

The theory is no different than stock except you integrate the catch can so the turbo doesn't suck oil. Imagine that, Mitsubishi came to a similar conclusion. You could combine this with a Bernoulli effect on the downpipe to obtain even more sucking power on the catchcan.

#298

Evolved Member

iTrader: (69)

What lines did you use, if you don't mind me asking? I am using a Stainless Steel -6AN line now, so hopefully that holds up, if not I can wrap them for insulation I guess. Regardless, if its sitting over night in 15 degree weather, it will get cold enough to the point where insulation won't provide enough protection. Hopefully the shorter, downhill route lines, running close to the engine will suffice.

Time will tell...

Oh, here is the oil analysis of the last run. Around 1,000 of those miles were with the PCV removed and running the VTA catch can.

Time will tell...

Oh, here is the oil analysis of the last run. Around 1,000 of those miles were with the PCV removed and running the VTA catch can.

#299

What lines did you use, if you don't mind me asking? I am using a Stainless Steel -6AN line now, so hopefully that holds up, if not I can wrap them for insulation I guess. Regardless, if its sitting over night in 15 degree weather, it will get cold enough to the point where insulation won't provide enough protection. Hopefully the shorter, downhill route lines, running close to the engine will suffice.

Time will tell...

Oh, here is the oil analysis of the last run. Around 1,000 of those miles were with the PCV removed and running the VTA catch can.

Time will tell...

Oh, here is the oil analysis of the last run. Around 1,000 of those miles were with the PCV removed and running the VTA catch can.

#300

I didn't read all the posts, but can give some feedback for relieving block pressure under boost. Some of my old buddies racing large turbo'd mustangs would run a dedicated belt driven vacuum pump to relieve crankcase pressure.

I had some buddies with N/A cars use the Bernoulli effect within the exhaust immediately after the header collector to pull vacuum on the block under WOT. I have read that some use it on turbo cars with good success, but not SMOG legal.

http://www.moroso.com/catalog/catego...?catcode=13023

The good thing about the EVO is that we have a vacuum pump onboard called a turbocharger. Keep the PCV to the intake manifold because it helps to evacuate the block under off boost situations.

Here is what I have done on several project cars. Run the block vents to a sealed catch can. The catch can is also hooked to the turbo inlet so that it can pull vacuum on the can during boost. Run a one way (out only) valve on the bottom of the catch can and have it return to the oil pan. Under boost the can will pull vacuum from the turbo inlet and help evacuate the block, but won't pull oil from the pan due to the one-way valve. Off boost the one way drain valve will open and allow oil to freely drain to the pan.

Oil cannot take turns like air so baffling within the catchcan will be important to separate air from oil.

I ran a similar setup on the twinturbo ZR1 and the can would register ~2in-mg vacuum when the car was ~7psi of boost. Not as much vacuum as you would like, but at least it wasn't positive pressure.

The theory is no different than stock except you integrate the catch can so the turbo doesn't suck oil. Imagine that, Mitsubishi came to a similar conclusion. You could combine this with a Bernoulli effect on the downpipe to obtain even more sucking power on the catchcan.

I had some buddies with N/A cars use the Bernoulli effect within the exhaust immediately after the header collector to pull vacuum on the block under WOT. I have read that some use it on turbo cars with good success, but not SMOG legal.

http://www.moroso.com/catalog/catego...?catcode=13023

The good thing about the EVO is that we have a vacuum pump onboard called a turbocharger. Keep the PCV to the intake manifold because it helps to evacuate the block under off boost situations.

Here is what I have done on several project cars. Run the block vents to a sealed catch can. The catch can is also hooked to the turbo inlet so that it can pull vacuum on the can during boost. Run a one way (out only) valve on the bottom of the catch can and have it return to the oil pan. Under boost the can will pull vacuum from the turbo inlet and help evacuate the block, but won't pull oil from the pan due to the one-way valve. Off boost the one way drain valve will open and allow oil to freely drain to the pan.

Oil cannot take turns like air so baffling within the catchcan will be important to separate air from oil.

I ran a similar setup on the twinturbo ZR1 and the can would register ~2in-mg vacuum when the car was ~7psi of boost. Not as much vacuum as you would like, but at least it wasn't positive pressure.

The theory is no different than stock except you integrate the catch can so the turbo doesn't suck oil. Imagine that, Mitsubishi came to a similar conclusion. You could combine this with a Bernoulli effect on the downpipe to obtain even more sucking power on the catchcan.

stock setup basically cept drilled 5/8 hole where the existing mini hole was on the driver side of valve cover and then ran that to catch then from catch can into the air intake (using the turbo as the vacuum pump)

then for intake manifold side: kept the pcv onboard + added another check valve directly after it (incase it leaks boost, which it will) and then another check valve shortly after that (because i had an extra left over lol) and then ran that to the 2nd catch can and then took the intake manifold side and ran that to the catch can with a check valve facing so it can not pressurize the catch can..

so basically i ran the stock setup still but put a catch can in the middle of it all, while also adding check valves + drilling bigger hole.

I will report back how this setup works so everyone knows and i will also check the turbo frequently to see if i get any oil residue in the air intake