Walbro 400 install and pump pressure/flow testing

#16

I was right about the pressure drop in the stock fuel line. I measured a whopping 16 psi pressure difference between the pump housing outlet and the fuel rail at WOT 7800 rpm just before I let off. Its probably 1-2 psi worse at the pump outlet itself.

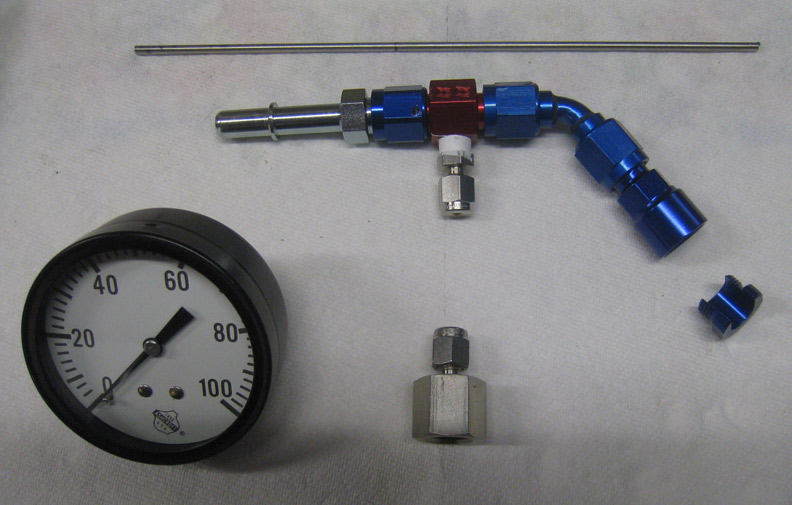

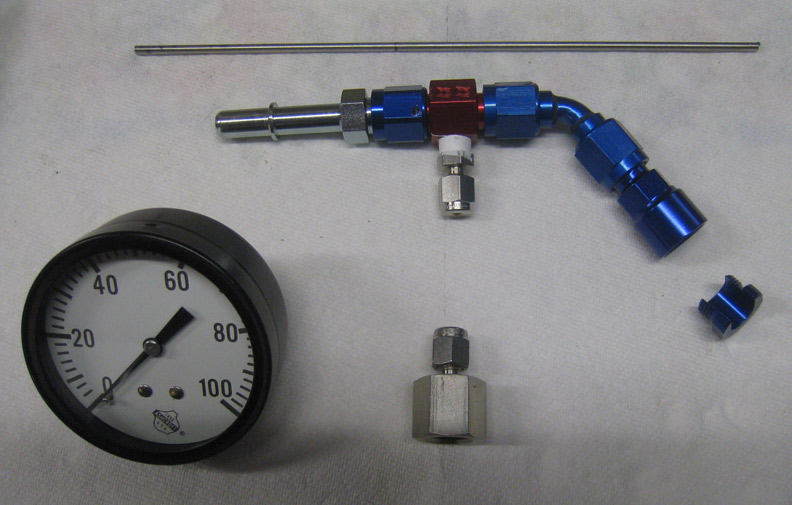

First set of pics below show the adapter I made up log fuel pressure. It just barely all fits in there. I had to tweak the 45 deg connector to get everything to line up. I would have loved to log outlet pressure using a pressure sensor, but it wasn't worth the cost of another sensor. I checked the accuracy of the gauge by starting the car, letting it warm up and then killing the motor. Fuel pressure holds high because the check valve in the pump outlet prevents pressure release. The gauge pressure matched the rail pressure of 43 psi pretty much exactly.

I ended up using my camera to make a video of the gauge during my WOT run. Worked like a charm and got good pressure data. The data plot shows pump outlet pressure sitting approximately 14 psi higher than fuel rail pressure for most of the run, and then as the motor revved out past 7500 rpm, the pressure difference increased to 16 psi with the pump housing outlet sitting at 84 psi just before I lifted. Fuel pressure directly at the pump outlet is probably 1-2 psi higher. During the run, I observed fuel pump voltage to be about 13 volts, so using the Walbro 400 data chart, I get an estimate pump flow rate of 250 lph at 85 psi and 13 volts. The FIC1100 injectors are at about 90% IDC (E85), so 90% * 4 injectors * 1.1 lpm *60 minutes = 237 lph. It all adds up pretty well, and basically what's happening at WOT is that my injectors are consuming all the available fuel that the pump can send with virtually none going down the return line. No eff'in wonder I can't maintain any margin of fuel pressure at the rail.

So there ya go. I think the bottom line is that anyone making more than 450 whp ought to considering running larger diameter fuel line from the pump housing to the rail. -6 AN is what most people run, and it should reduce the pressure drop to less than 5 psi at 500 whp of E85 fuel flow. Its either that or run a boost-a-pump, but that will likely drive pump outlet pressure up to 90+ psi where the pump flow begins to fall like a rock.

One other comment I'll make is that running -6 AN line will likely allow a Walbro 255 or DW300 to support significantly more power. My guess is that anyone who has been able to make more than 500 whp on either of these pumps with E85 was running upgraded fuel lines or a boost-a-pump. Either that or their fuel pressure was falling off without them knowing it.

Adapter assembly to allow monitoring fuel pump outlet housing using stock fuel feed lines. The adapter that attaches to the pump housing is Russell PN 644120 (I had previously incorrectly listed it as 670340). Its sweet. They also make one with a -8 AN outlet.

Here's the installed adapter assembly. It just barely fit.

Video of the gauge during the WOT run. I double-stick taped my point-and-shoot camera to the back of the console. Kinda cracks me up.

http://youtu.be/6oueiLW-5P0

Here's the data plot. Currently making at least 485 whp DJ. Might be closer to 500 whp.

Here is the Walbro 400 flow data. Pump was at 13 V and 84 psi at liftoff. Interpolating between 85-90 psi and 12-13.5 volts, I get about 250 lph of flow which is just barely enough for 500 whp.

First set of pics below show the adapter I made up log fuel pressure. It just barely all fits in there. I had to tweak the 45 deg connector to get everything to line up. I would have loved to log outlet pressure using a pressure sensor, but it wasn't worth the cost of another sensor. I checked the accuracy of the gauge by starting the car, letting it warm up and then killing the motor. Fuel pressure holds high because the check valve in the pump outlet prevents pressure release. The gauge pressure matched the rail pressure of 43 psi pretty much exactly.

I ended up using my camera to make a video of the gauge during my WOT run. Worked like a charm and got good pressure data. The data plot shows pump outlet pressure sitting approximately 14 psi higher than fuel rail pressure for most of the run, and then as the motor revved out past 7500 rpm, the pressure difference increased to 16 psi with the pump housing outlet sitting at 84 psi just before I lifted. Fuel pressure directly at the pump outlet is probably 1-2 psi higher. During the run, I observed fuel pump voltage to be about 13 volts, so using the Walbro 400 data chart, I get an estimate pump flow rate of 250 lph at 85 psi and 13 volts. The FIC1100 injectors are at about 90% IDC (E85), so 90% * 4 injectors * 1.1 lpm *60 minutes = 237 lph. It all adds up pretty well, and basically what's happening at WOT is that my injectors are consuming all the available fuel that the pump can send with virtually none going down the return line. No eff'in wonder I can't maintain any margin of fuel pressure at the rail.

So there ya go. I think the bottom line is that anyone making more than 450 whp ought to considering running larger diameter fuel line from the pump housing to the rail. -6 AN is what most people run, and it should reduce the pressure drop to less than 5 psi at 500 whp of E85 fuel flow. Its either that or run a boost-a-pump, but that will likely drive pump outlet pressure up to 90+ psi where the pump flow begins to fall like a rock.

One other comment I'll make is that running -6 AN line will likely allow a Walbro 255 or DW300 to support significantly more power. My guess is that anyone who has been able to make more than 500 whp on either of these pumps with E85 was running upgraded fuel lines or a boost-a-pump. Either that or their fuel pressure was falling off without them knowing it.

Adapter assembly to allow monitoring fuel pump outlet housing using stock fuel feed lines. The adapter that attaches to the pump housing is Russell PN 644120 (I had previously incorrectly listed it as 670340). Its sweet. They also make one with a -8 AN outlet.

Here's the installed adapter assembly. It just barely fit.

Video of the gauge during the WOT run. I double-stick taped my point-and-shoot camera to the back of the console. Kinda cracks me up.

http://youtu.be/6oueiLW-5P0

Here's the data plot. Currently making at least 485 whp DJ. Might be closer to 500 whp.

Here is the Walbro 400 flow data. Pump was at 13 V and 84 psi at liftoff. Interpolating between 85-90 psi and 12-13.5 volts, I get about 250 lph of flow which is just barely enough for 500 whp.

Last edited by mrfred; May 2, 2012 at 06:09 AM.

The following users liked this post:

Talonboost (Dec 24, 2016)

#17

Evolved Member

iTrader: (5)

Dude, this is AWESOME info and testing. Thanks for taking the time to do it and share your conclusions.

BTW, I maxed out Buscher's double pumper system (through the stock fuel lines) at about 760whp on a Mustang dyno on E-85.

I just switched everything over to a -8 feed and -6 return along with two new Walbro 400 s on the double-pumper. Will be shooting for 850-900 in a few weeks.

BTW, I maxed out Buscher's double pumper system (through the stock fuel lines) at about 760whp on a Mustang dyno on E-85.

I just switched everything over to a -8 feed and -6 return along with two new Walbro 400 s on the double-pumper. Will be shooting for 850-900 in a few weeks.

#18

Dude, this is AWESOME info and testing. Thanks for taking the time to do it and share your conclusions.

BTW, I maxed out Buscher's double pumper system (through the stock fuel lines) at about 760whp on a Mustang dyno on E-85.

I just switched everything over to a -8 feed and -6 return along with two new Walbro 400 s on the double-pumper. Will be shooting for 850-900 in a few weeks.

BTW, I maxed out Buscher's double pumper system (through the stock fuel lines) at about 760whp on a Mustang dyno on E-85.

I just switched everything over to a -8 feed and -6 return along with two new Walbro 400 s on the double-pumper. Will be shooting for 850-900 in a few weeks.

I'll bet that pump pressure was 95-ish psi when you were running double-pumpers on the stock fuel line. Net fuel injector pressure was probably falling to about 20-35 psi depending on your boost level. You'll have massive amounts of flow with your new setup, probably 3x the flow capacity.

#20

EvoM Guru

iTrader: (1)

mrfred, so your saying your fic1100's are at 90% duty cycle with the 400 pump? That seems odd to me like something else is up with you car as my afi 1000s with a jay racing pt342 pump with a fuel pump re-wire is only at 88% duty cycle and my car makes 619whp on a dynojet. I was able to make 550 on a dynojet with a 255 before I could no longer keep control of my afr. Wish I could log everything you did like you did to show a comparison. I was looking at the 400 pump and id2000's soon to do race gas and look for like 750

Awesome testing results, it's always a great feeling to prove yourself right with solid data. Well done

#23

I've now got Earl's -6 AN braided stainless teflon hose installed from the pump to the rail. What a PITA... took me most of the day to get it installed reasonably cleanly. Below is a pic of the fittings I used to mate the hose to the fuel pump outlet. Total cost of fittings and hose was around $120. The hose is super tough and impervious to any fuel, but its super stiff. If I were to do it again, I'd be tempted to use Earl's high-end hose with the ultra flexible teflon and kevlar braid. Its 4x the cost though. At any rate, the -6 AN hose had virtually no flow restriction, and pressure at the pump outlet was only ~3 psi higher than pressure at the fuel rail. That's a 12-13 psi pressure reduction which is good for about another 50 lph of fuel. Net injector pressure now looks to be holding 44 psi across pretty much up to max fuel requirements.

Fittings at the fuel pump outlet

Log showing only ~3 psi difference between pump outlet pressure and fuel rail pressure

Fittings at the fuel pump outlet

Log showing only ~3 psi difference between pump outlet pressure and fuel rail pressure

The following users liked this post:

Talonboost (Dec 24, 2016)

#24

Evolved Member

iTrader: (33)

At any rate, the -6 AN hose had virtually no flow restriction, and pressure at the pump outlet was only ~3 psi higher than pressure at the fuel rail. That's a 12-13 psi pressure reduction which is good for about another 50 lph of fuel. Net injector pressure now looks to be holding 44 psi across pretty much up to max fuel requirements.

#27

btw, russell also makes the same fitting in a direct push on model.

http://www.summitracing.com/parts/RUS-640853/

http://www.summitracing.com/parts/RUS-640853/

Factory fuel supply line?

#28

mfred, in post #16 you're listing the adapter that attaches to the pump housing as a Russell PN 670340.

But when I check on the Summit Racing website, it shows a Russell Fuel Pressure Take-Off :

http://www.summitracing.com/parts/RUS-670340/

Would be great if you could list the part number of the adapter to the pump housing in -6AN and or -8 AN.

Thanks for your help and testing!

But when I check on the Summit Racing website, it shows a Russell Fuel Pressure Take-Off :

http://www.summitracing.com/parts/RUS-670340/

Would be great if you could list the part number of the adapter to the pump housing in -6AN and or -8 AN.

Thanks for your help and testing!