internal wastegate setup tip.

#1

internal wastegate setup tip.

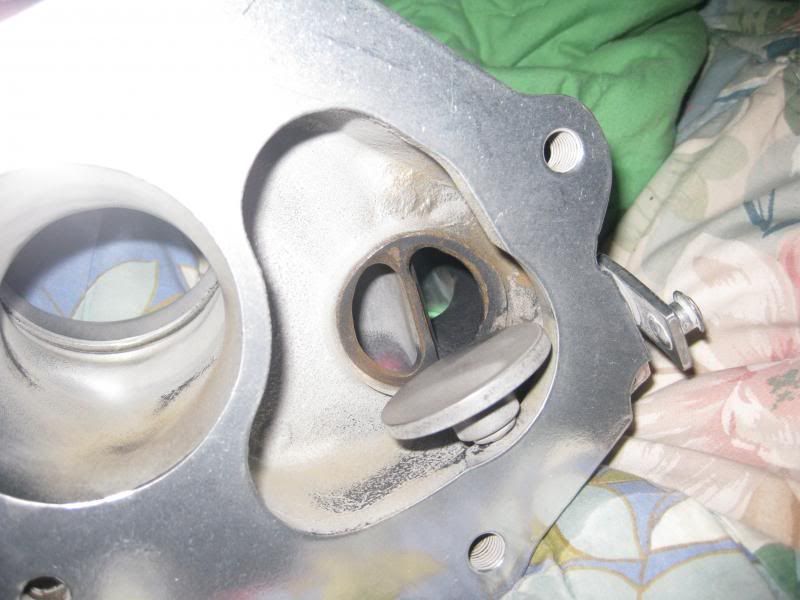

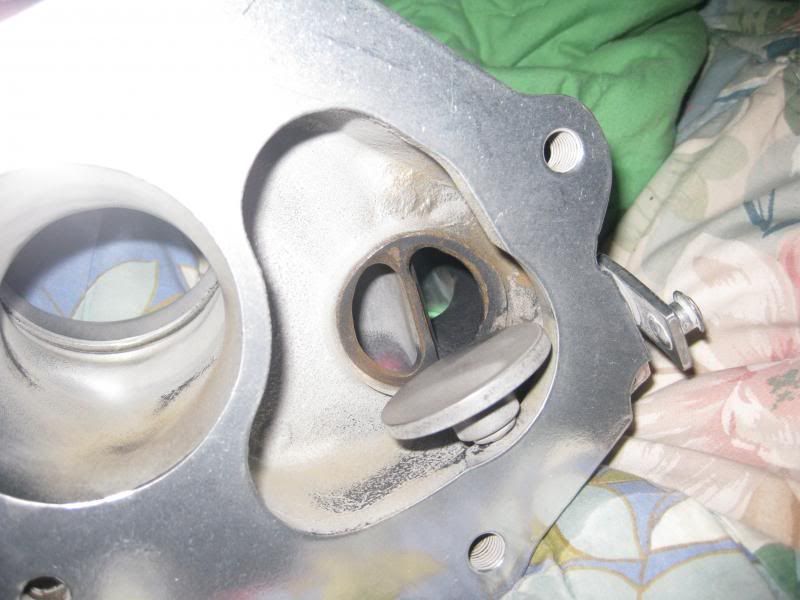

I have been meaning to share this for quite some time. I have seen ported turbos from Buschar, MAP, FP, CBRD, and even curt browns personall FP red. I have not seen anyone else do this. I have seen the back to back results of this porting and its absolutely monster on how well the turbine side works. its actually far more important than porting the inlets.

Some short tech on how the wastegate works. for one its important to understand if you set your boost controller to 20psi the wastegate doesnt suddeny fire open at 20psi. it will over come the spring pressure at maybe 12psi and slowly open farther and farther to the set 20psi. when the flapper lifts off the seat you loose torque as the twin scroll effect is lost. So when you raise the boost to say 30psi the torque rises dramatically. this is because of course you are running higher boost but masked inside this the flapper is staying on its seat longer. this is why you see higher boost pressures "spool" the turbo faster.

So to set the turbo up for fast spool and better high rpm power you want to run higher spring pre-loads on the gate. what this means is the flapper itself is simply opening less at crack pressure and wide open. problems with doing this is you can get a mean boost spike as excess boost building back pressure cant get out past the smaller opening.

So the simple trick is to port the wastegate so it flows well at small openings. rounding off the sharp corners works extremely well. ask any head porter how a one valve job flows and they will laugh at you. I have seen 4-5psi boost spikes reduced to nearly zero with doing this.

advatages:

eliminate spikes

allows flatter boost curves

lowers turbine back pressure and for more hp at less boost (more flow around turbine)

allows tighter pre loads for faster spool and better high rpm holding

Some short tech on how the wastegate works. for one its important to understand if you set your boost controller to 20psi the wastegate doesnt suddeny fire open at 20psi. it will over come the spring pressure at maybe 12psi and slowly open farther and farther to the set 20psi. when the flapper lifts off the seat you loose torque as the twin scroll effect is lost. So when you raise the boost to say 30psi the torque rises dramatically. this is because of course you are running higher boost but masked inside this the flapper is staying on its seat longer. this is why you see higher boost pressures "spool" the turbo faster.

So to set the turbo up for fast spool and better high rpm power you want to run higher spring pre-loads on the gate. what this means is the flapper itself is simply opening less at crack pressure and wide open. problems with doing this is you can get a mean boost spike as excess boost building back pressure cant get out past the smaller opening.

So the simple trick is to port the wastegate so it flows well at small openings. rounding off the sharp corners works extremely well. ask any head porter how a one valve job flows and they will laugh at you. I have seen 4-5psi boost spikes reduced to nearly zero with doing this.

advatages:

eliminate spikes

allows flatter boost curves

lowers turbine back pressure and for more hp at less boost (more flow around turbine)

allows tighter pre loads for faster spool and better high rpm holding

#3

It will also help you reduce boost creep if that is a problem for you without messing with the inlet side. It's how I reduced the problem on my DSM because the flappers on 16g's don't open very far with the stock wastegate.

Last edited by Ag4G63; Mar 6, 2014 at 12:31 PM.

#6

I wouldnt leave the divider untouched. I have done this many times and it works fantastic. The picture is funky. it accentuates the shiny spots. There is actually at least 2mm of seat retained everywhere. no loss of twin scroll effect when valve is seated. i should ad this is very difficult porting to do. this is done with a dremel, a small bit , and lots of patience. its very difficult to cut the edge without the bit walking off. ideally you cut at angles that allows bit to walk in direction that wont hurt the seat. but thats not possible unless you have a reverse cut bit and reversing grinder. you could also take the time to make little plates that protect the seat you dont want cut. in the end the marks left on the seat are not gonna effect seal enough to matter. they will fill with carbon when run just like deteriorating valve seats in the cylinder head.

here is another housing with ceramic coating I use. ready to go to work. better angle how much seat width I try to leave.

here is another housing with ceramic coating I use. ready to go to work. better angle how much seat width I try to leave.

Last edited by 94AWDcoupe; Mar 7, 2014 at 07:56 AM.

Trending Topics

The following users liked this post:

fugiwara (Sep 26, 2016)

#10

EvoM Guru

iTrader: (1)

Next time my turbo is off I think I'll give this a shot. Maybe practice porting the waste gate area on the busted housing that I have.

Thread

Thread Starter

Forum

Replies

Last Post

94AWDcoupe

Evo Engine / Turbo / Drivetrain

92

Feb 18, 2017 08:17 PM

94AWDcoupe

Evo Engine / Turbo / Drivetrain

61

Jun 24, 2016 06:19 PM

FS[SouthEast]: AMA Moroso oil pan

94AWDcoupe

For Sale/WTB - Engine / Drivetrain / Power

1

Jun 9, 2016 11:06 PM

94AWDcoupe

For Sale/WTB - Engine / Drivetrain / Power

7

Jun 9, 2016 11:05 PM

94AWDcoupe

For Sale/WTB - Engine / Drivetrain / Power

19

May 1, 2016 08:44 PM