nitrous wiring question

#1

nitrous wiring question

After spending countless hours researching running nitrous and comming to a decison its time for the next step. Time to figure out the wiring with the AEM. Luckily, I found a diagram in the aem user guide but it seemed to be only for a dry system. I plan on running a wet system so it wasnt exactly what i needed. I thought at first i could just use the one relay and splice it into the other solenoid. Simple enough. However, that isnt the case apearently. I came across an article on chevy performance on wiring a wet system and it said that each solenoid needs its own relay. So its time to get to work.

I plan on running a fuel pressure switch so that added to the confusion becuase the diagram in the AEM user guide didnt have one.

I dont have a throttle microswitch becuase the AEM takes care of that so thats one less thing to wire, thank god.

So I took both diagrams and came up with how i think it should be ran.

Below are the 2 diagrams i used and then my attempt at how i think it should be ran. Please let me know if it is correct.

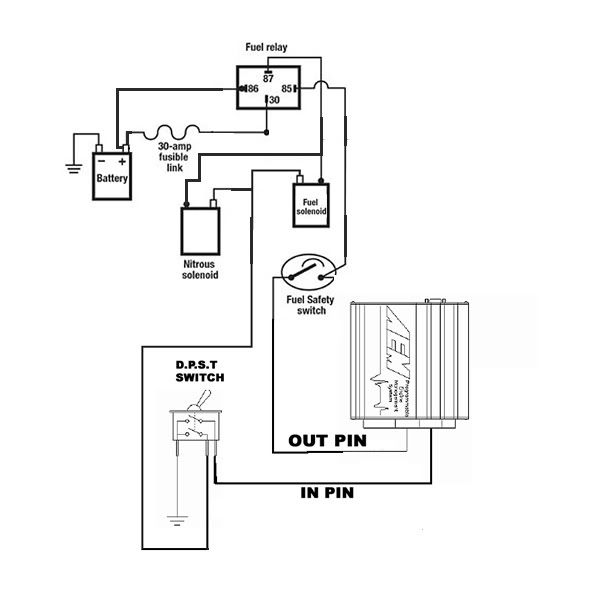

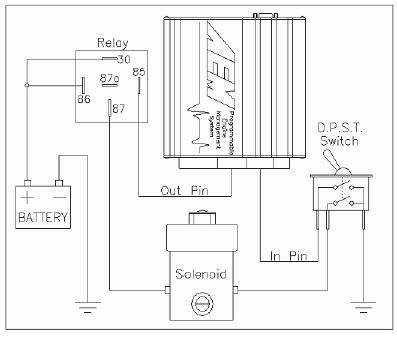

here is the diagram from the aem user guide:

*as you can see only one solenoid and no fuel pressure switch...

Here is the link to the Chevy Performance article:

http://www.chevyhiperformance.com/te...itrous_system/

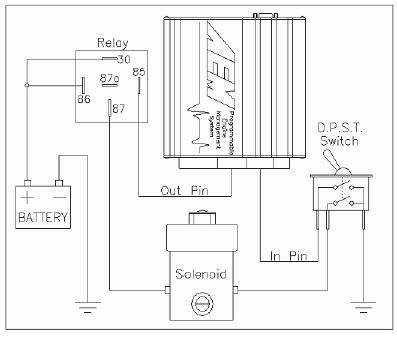

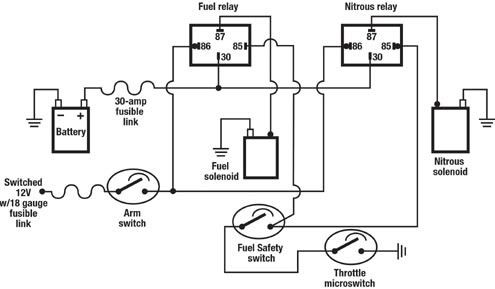

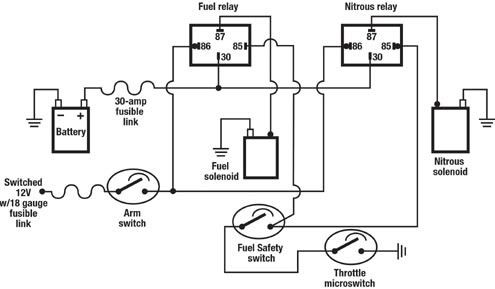

Here is the diagram from Chevy Performance:

As you can see in the Chevy Performance Diagram they have an arm switch to turn the system on which i wont be using the way they have it cuz the AEM diagram has the switch on the in pin location. So i took out that switch and ran the wires straight to the battery like in the AEM diagram. The also have the throttle micsroswitch to engage it which I figured the AEM would take its place.

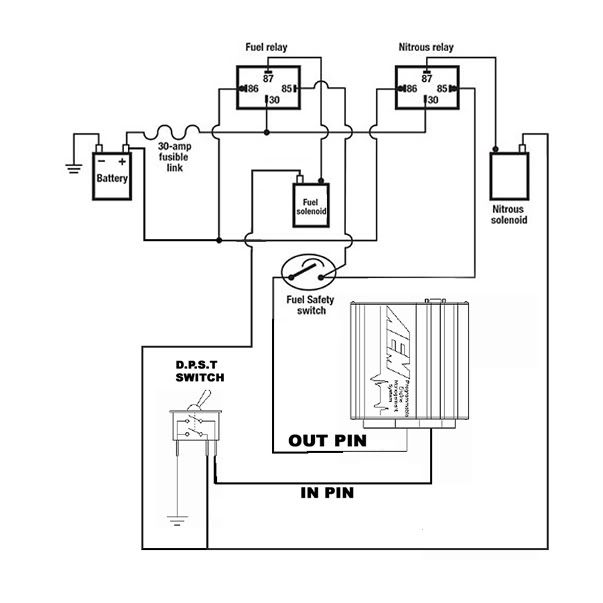

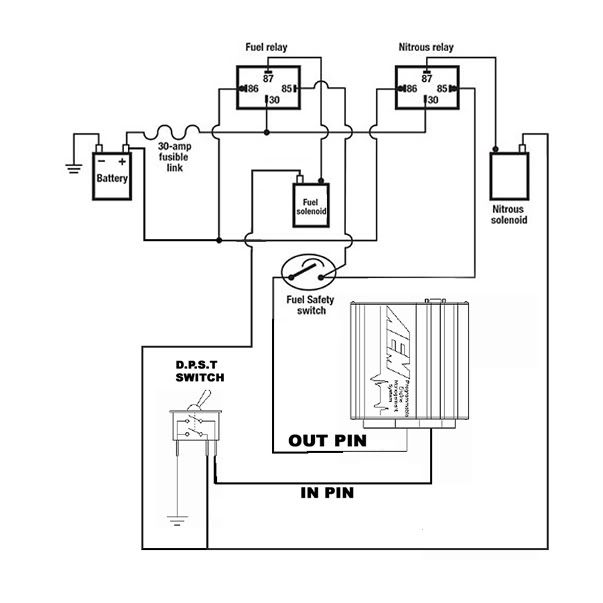

Here is what i came up with:

Does this look correct? Any input is appreciated.

Hopefully its correct so others can use my diagram as well.

ERIK

I plan on running a fuel pressure switch so that added to the confusion becuase the diagram in the AEM user guide didnt have one.

I dont have a throttle microswitch becuase the AEM takes care of that so thats one less thing to wire, thank god.

So I took both diagrams and came up with how i think it should be ran.

Below are the 2 diagrams i used and then my attempt at how i think it should be ran. Please let me know if it is correct.

here is the diagram from the aem user guide:

*as you can see only one solenoid and no fuel pressure switch...

Here is the link to the Chevy Performance article:

http://www.chevyhiperformance.com/te...itrous_system/

Here is the diagram from Chevy Performance:

As you can see in the Chevy Performance Diagram they have an arm switch to turn the system on which i wont be using the way they have it cuz the AEM diagram has the switch on the in pin location. So i took out that switch and ran the wires straight to the battery like in the AEM diagram. The also have the throttle micsroswitch to engage it which I figured the AEM would take its place.

Here is what i came up with:

Does this look correct? Any input is appreciated.

Hopefully its correct so others can use my diagram as well.

ERIK

Last edited by SubiEvolved; Apr 18, 2007 at 11:04 PM.

#2

In the past i have always ran one relay for both solenoids. i was scared if the fuel relay would fail i would be in trouble. There are many different thoughts on this but to me its one less thing to fail and less wiring.

#4

Looks good. Nice and simple less things to fail and cause problems.

This will be the exact same way i wire mine. Make sure when you purchase your switch it is dual contacts and they rated for a about 20 amps since the full current of the solenoids will be passing through it. Each manufacture of solenoids draws a bit different current but i think the max is about 10 amps. The No2 solenoid draws way more current than the fuel solenoid.

This will be the exact same way i wire mine. Make sure when you purchase your switch it is dual contacts and they rated for a about 20 amps since the full current of the solenoids will be passing through it. Each manufacture of solenoids draws a bit different current but i think the max is about 10 amps. The No2 solenoid draws way more current than the fuel solenoid.

#5

Newbie

Join Date: Oct 2005

Location: RRev Motorsports

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

I would set up your arm switch separate from the nitrous power wiring, that way when you switch the arm switch for the nitrous you can setup the AEM to pull timing and adjust fuel for when the nitrous is running. If you set up the arm switch the way that you have it you will have to have the nitrous control in the AEM "always on" which will eliminate your ability to adjust the timing.

Cliff notes:

Wire up a switch that goes from ground and then to a switch input in the AEM (ex. Switch 1), then setup the AEM so that the NOS switch in (ex. switch #1 Gnd =on). The rest of your wiring should be the same as above (excluding the arm switch). With that setup you can have an aggresive timing map, and then pull timing and arm the nitrous when the arm switch is activated.

Cliff notes:

Wire up a switch that goes from ground and then to a switch input in the AEM (ex. Switch 1), then setup the AEM so that the NOS switch in (ex. switch #1 Gnd =on). The rest of your wiring should be the same as above (excluding the arm switch). With that setup you can have an aggresive timing map, and then pull timing and arm the nitrous when the arm switch is activated.

#6

I would set up your arm switch separate from the nitrous power wiring, that way when you switch the arm switch for the nitrous you can setup the AEM to pull timing and adjust fuel for when the nitrous is running. If you set up the arm switch the way that you have it you will have to have the nitrous control in the AEM "always on" which will eliminate your ability to adjust the timing.

Cliff notes:

Wire up a switch that goes from ground and then to a switch input in the AEM (ex. Switch 1), then setup the AEM so that the NOS switch in (ex. switch #1 Gnd =on). The rest of your wiring should be the same as above (excluding the arm switch). With that setup you can have an aggresive timing map, and then pull timing and arm the nitrous when the arm switch is activated.

Cliff notes:

Wire up a switch that goes from ground and then to a switch input in the AEM (ex. Switch 1), then setup the AEM so that the NOS switch in (ex. switch #1 Gnd =on). The rest of your wiring should be the same as above (excluding the arm switch). With that setup you can have an aggresive timing map, and then pull timing and arm the nitrous when the arm switch is activated.

What kinda parameters do you gus run on the nitrous??? IE: min/max rpm, TPS%, reinstate load, VSS

ERIK

#7

I would set up your arm switch separate from the nitrous power wiring, that way when you switch the arm switch for the nitrous you can setup the AEM to pull timing and adjust fuel for when the nitrous is running. If you set up the arm switch the way that you have it you will have to have the nitrous control in the AEM "always on" which will eliminate your ability to adjust the timing.

.

.

Trending Topics

#8

Newbie

Join Date: Oct 2005

Location: RRev Motorsports

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Let me see if i understand correctly. The way i have it wired in my diagram i would load the nitrous map on the aem in the car it would run the nitrous timing whether the switch is on or off. If i wire it the way you say i can have the nitrous map in the aem and when the switch is not on the car will run the normal race gas timing, and when the switch is flipped it will go to the nitrous timing?? So i wouldnt have to load a map for race gas when im not spraying and a map nitrous when i am, i could just use one??

What kinda parameters do you gus run on the nitrous??? IE: min/max rpm, TPS%, reinstate load, VSS

ERIK

What kinda parameters do you gus run on the nitrous??? IE: min/max rpm, TPS%, reinstate load, VSS

ERIK

Yes, with the wire diagram you provided you will run the nitrous timing at all times, but if you run a switched input as I recommended you will only run the nitrous timing when you flip the "nitrous arm" switch. This will allow you to have a race gas tune in your car (no nitrous), and then flip the switch and use the nitrous ignition map to pull timing when the nitrous is on. My way will simpify things and allow for you to not have to load a different map when you want to use the nitrous.

As for the parameters, what do you want to use the nitrous for? For spooling the turbo or for top end???

One thing that you want to remember is to have the nitrous turn off before the RPM fuel cut, and be careful when using the load based fuel cut. If you cut the fuel with the nitrous on you risk having a nitrous backfire.

#9

Newbie

Join Date: Oct 2005

Location: RRev Motorsports

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

One thing to note on the AEM (at least on the Supra box, I am not 100% on the EVO box) is to use low side 6 or higher to arm the nitrous when using the switched input. On the supra EMS if you use LS 1-5 and accidentally leave the nitrous arm switch on, you risk a nitrous backfire.

When you key the car on LS1-5 automatically cycle, which could cause the nitrous to fire for a short period during cranking....and risk a backfire.

When you key the car on LS1-5 automatically cycle, which could cause the nitrous to fire for a short period during cranking....and risk a backfire.

#10

Erik,

Yes, with the wire diagram you provided you will run the nitrous timing at all times, but if you run a switched input as I recommended you will only run the nitrous timing when you flip the "nitrous arm" switch. This will allow you to have a race gas tune in your car (no nitrous), and then flip the switch and use the nitrous ignition map to pull timing when the nitrous is on. My way will simpify things and allow for you to not have to load a different map when you want to use the nitrous.

As for the parameters, what do you want to use the nitrous for? For spooling the turbo or for top end???

One thing that you want to remember is to have the nitrous turn off before the RPM fuel cut, and be careful when using the load based fuel cut. If you cut the fuel with the nitrous on you risk having a nitrous backfire.

Yes, with the wire diagram you provided you will run the nitrous timing at all times, but if you run a switched input as I recommended you will only run the nitrous timing when you flip the "nitrous arm" switch. This will allow you to have a race gas tune in your car (no nitrous), and then flip the switch and use the nitrous ignition map to pull timing when the nitrous is on. My way will simpify things and allow for you to not have to load a different map when you want to use the nitrous.

As for the parameters, what do you want to use the nitrous for? For spooling the turbo or for top end???

One thing that you want to remember is to have the nitrous turn off before the RPM fuel cut, and be careful when using the load based fuel cut. If you cut the fuel with the nitrous on you risk having a nitrous backfire.

#11

brobards,

im still a little confused in what your saying. Sorry i must not be quite awake yet. lol.

You want me to run 2 switches? One to power the nitrous and the other to arm the aem??? I would replace the dpst switch with a reg switch and just have it power the aem? Then add another reg switch to arm the nitrous?

Or are you talking about the switch inputs in the aem nitrous parameters, IE LS1, etc??

im still a little confused in what your saying. Sorry i must not be quite awake yet. lol.

You want me to run 2 switches? One to power the nitrous and the other to arm the aem??? I would replace the dpst switch with a reg switch and just have it power the aem? Then add another reg switch to arm the nitrous?

Or are you talking about the switch inputs in the aem nitrous parameters, IE LS1, etc??

Last edited by SubiEvolved; Apr 23, 2007 at 07:37 AM.

#12

Newbie

Join Date: Oct 2005

Location: RRev Motorsports

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

You would only need one switch, to act as an arming switch. What I usually do because it is easier is to run the switch to a ground on one side and then to a switched input (switch #4 is available on the 1313 EMS pin 7).

You would then setup the nitrous tables so that it will only be on when the switch is grounded (NOS Switch In : Switch #4 GND=On)

You would then setup the nitrous tables so that it will only be on when the switch is grounded (NOS Switch In : Switch #4 GND=On)

#13

Sorry if im not getting it. i suck at wiring. It's been a long week and trying not to have to wire it more than once. lol

Last edited by SubiEvolved; Apr 24, 2007 at 05:56 PM.

#14

Newbie

Join Date: Oct 2005

Location: RRev Motorsports

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

In order to get the relay for the solenoids to ground you will use the available low side outputs in the AEM.

In the options of the nitrous map in the AEM you will need to input what switched input you are using to activate the nitrous map (red box in attached picture), and you will have to input what low side output you will be using to trigger the nitrous solenoids (yellow box in attached picture). As I can not draw a picture for you I will try to describe how it should be wired.

Nitrous Arm:

Chassis Ground ---> Arming switch (toggle switch) -----> AEM Switched input (ex. switch#4 GND=on)

Nitrous wiring:

AEM low side output (ex. LS6) ---> Ground on relay (85)

Switched Power side of relay (87) ---> Positive of fuel and nitrous solenoids

Ground of fuel and nitrous solenoids ----> chassis ground

THESE ARE TWO SEPARATE CIRCUITS, ONE FOR THE NITROUS ARM, ONE FOR THE SOLENOID WIRING.

In the options of the nitrous map in the AEM you will need to input what switched input you are using to activate the nitrous map (red box in attached picture), and you will have to input what low side output you will be using to trigger the nitrous solenoids (yellow box in attached picture). As I can not draw a picture for you I will try to describe how it should be wired.

Nitrous Arm:

Chassis Ground ---> Arming switch (toggle switch) -----> AEM Switched input (ex. switch#4 GND=on)

Nitrous wiring:

AEM low side output (ex. LS6) ---> Ground on relay (85)

Switched Power side of relay (87) ---> Positive of fuel and nitrous solenoids

Ground of fuel and nitrous solenoids ----> chassis ground

THESE ARE TWO SEPARATE CIRCUITS, ONE FOR THE NITROUS ARM, ONE FOR THE SOLENOID WIRING.

#15

Evolved Member

iTrader: (4)

I may not be following this thread correctly, but with the AEM circuit diagram, they are also two seperate circuits. The switch is a double pole unit. The reason that is in place is to prevent the EMS from activating the solenoids inadvertently when the arming switch is off. I have to agree that I do like a hardwired switch on the solenoid circuit. You can use two switches, which would be retarded, or use a DPST switch as shown in the AEM diagram.

I won't be wiring up the nitrous to the AEM until later this week, but since I set it up for DSMlink, both solenoids are on one relay. IIRC, it was only about 8 amps total, but I haven't looked at the specs in a long time.

While we're on the topic, I wish the AEM had two switch input fields, so I could set the nitrous to deactivate when it sees the clutch switch. I may run it with no arming input to the AEM and just toggle the nitrous maps on manually, so I can set the switch input to switch #4 GND=off and be done with it. With a wet kit you're able to jet it so you don't really need seperate fuel map/modifier, but the timing retard is nice. But enough rambling... I think I'll just set it up to mimick what I did with DSMlink.

I won't be wiring up the nitrous to the AEM until later this week, but since I set it up for DSMlink, both solenoids are on one relay. IIRC, it was only about 8 amps total, but I haven't looked at the specs in a long time.

While we're on the topic, I wish the AEM had two switch input fields, so I could set the nitrous to deactivate when it sees the clutch switch. I may run it with no arming input to the AEM and just toggle the nitrous maps on manually, so I can set the switch input to switch #4 GND=off and be done with it. With a wet kit you're able to jet it so you don't really need seperate fuel map/modifier, but the timing retard is nice. But enough rambling... I think I'll just set it up to mimick what I did with DSMlink.