for anyone that has crankcase pressure issues

#991

Evolving Member

iTrader: (3)

Join Date: Sep 2014

Location: Colorado

Posts: 171

Likes: 0

Received 0 Likes

on

0 Posts

Bottom line is that the factory setup is a joke, and you may very well need to improve on it. What pistons/clearance on your motor?

I have 4 "breathers" on my motor now. (I modified my dipstick to have a 5/8" out line near the top, like the one STM sells). Even just knocking out the plug on the pcv location and putting in a big line there might be enough unless your motor is like mine

#993

Evolved Member

iTrader: (37)

I just installed the STM tranny mounted 3 port catch can modified. It uses two -6an ports and one -10 an port.

-10an fitting off of the rear valve cover port

-6an off balance shaft inspection hole

-6an off side valve cover port

I will report back how much oil it traps after I am tuned.

-10an fitting off of the rear valve cover port

-6an off balance shaft inspection hole

-6an off side valve cover port

I will report back how much oil it traps after I am tuned.

#994

Evolving Member

iTrader: (10)

Not sure what your idea of "pretty strong" is (not being a jerk, just saying). But different motors are different. Having some dinky breather lines on my motor wasn't even close to enough venting as some of these guys get away with. My JE pistons are pretty loose. And I had the crankcase pressure to show for it

Bottom line is that the factory setup is a joke, and you may very well need to improve on it. What pistons/clearance on your motor?

I have 4 "breathers" on my motor now. (I modified my dipstick to have a 5/8" out line near the top, like the one STM sells). Even just knocking out the plug on the pcv location and putting in a big line there might be enough unless your motor is like mine

Bottom line is that the factory setup is a joke, and you may very well need to improve on it. What pistons/clearance on your motor?

I have 4 "breathers" on my motor now. (I modified my dipstick to have a 5/8" out line near the top, like the one STM sells). Even just knocking out the plug on the pcv location and putting in a big line there might be enough unless your motor is like mine

#995

Evolved Member

iTrader: (27)

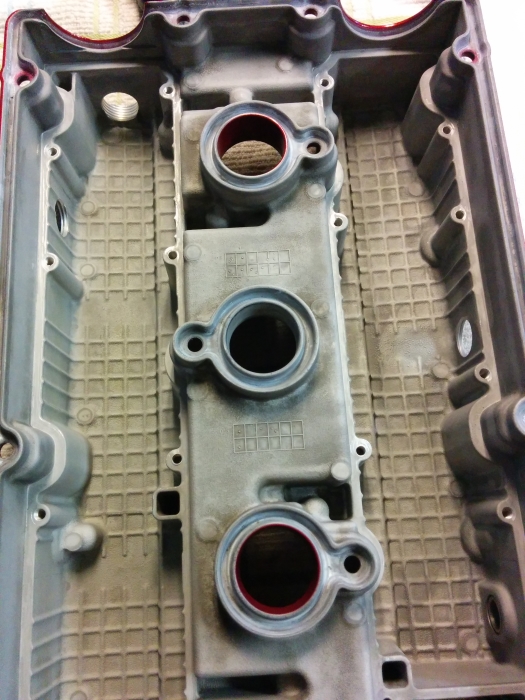

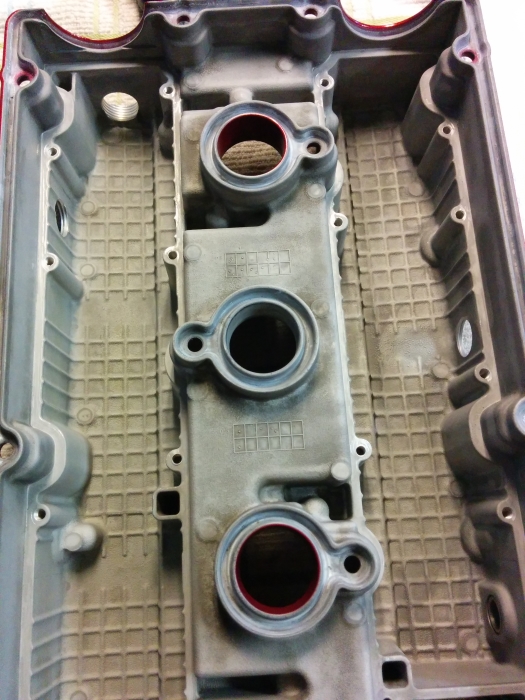

Here's some pics of mine as I slowly finish it, maybe if I feel like it I'll make a thread when it's all done. As Tom pointed out to me, if you open up the intake cam tranny side of the rocker cover, you will defeat the factory baffling vapor path as a few others have done here I can see. When you look at the baffles it will make sense. Where I placed my holes on the rocker cover, the factory baffling flow path can still be used so it shouldn't puke everywhere. Everything done on our end mill.

#997

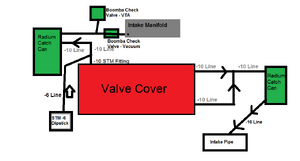

Not an EVO but my approach for the crankcase pressure relief is as follows..

- 2xAN10 from the VC

- 1.5" tube coming from the block

3 entries in the catch can enter the right part of it..after some baffling air is forced at the bottom and its way up where it meets the drilled plate..

Steel wool is placed on top of this plate...

What is drained from the baffles and the steel wool is collected in a sump and a 1/8npt valve is attached to easily drain the can..

Instead of using common round breather filters i used a small panel k&n filter (idea taken from "sheepey built" can)..

Here is the final product..

At first I wanted to make a AN10 return to the turbo intake..

- 2xAN10 from the VC

- 1.5" tube coming from the block

3 entries in the catch can enter the right part of it..after some baffling air is forced at the bottom and its way up where it meets the drilled plate..

Steel wool is placed on top of this plate...

What is drained from the baffles and the steel wool is collected in a sump and a 1/8npt valve is attached to easily drain the can..

Instead of using common round breather filters i used a small panel k&n filter (idea taken from "sheepey built" can)..

Here is the final product..

At first I wanted to make a AN10 return to the turbo intake..

#998

Evolved Member

iTrader: (39)

Drilling anywhere there isn't sufficient baffling in the valve cover to control oil slosh is going to result in prematurely filling of the catch can(s).

That said, be careful where you drill new openings. Its best to just drill out the existing openings only as that is how the baffling is setup inside to accommodate for the stock position openings.

I have no troublesome blowby anymore even with my power level over 800whp with no catch cans or anything anymore. regular stock PCV, nothing special. The only thing I have is the valve cover existing factory outlet on trans side opened to 5/8" and nothing attached to that either. Just a direct vent and nothing ever comes out and the intake is dry inside last time i checked.

That said, be careful where you drill new openings. Its best to just drill out the existing openings only as that is how the baffling is setup inside to accommodate for the stock position openings.

I have no troublesome blowby anymore even with my power level over 800whp with no catch cans or anything anymore. regular stock PCV, nothing special. The only thing I have is the valve cover existing factory outlet on trans side opened to 5/8" and nothing attached to that either. Just a direct vent and nothing ever comes out and the intake is dry inside last time i checked.

#1001

Former Sponsor

iTrader: (31)

No. This is my current setup https://www.facebook.com/media/set/?...7302897&type=3

I got rid of the FP black about 3 years ago or around there.

I got rid of the FP black about 3 years ago or around there.

#1002

Evolved Member

iTrader: (41)

Drilling anywhere there isn't sufficient baffling in the valve cover to control oil slosh is going to result in prematurely filling of the catch can(s).

That said, be careful where you drill new openings. Its best to just drill out the existing openings only as that is how the baffling is setup inside to accommodate for the stock position openings.

I have no troublesome blowby anymore even with my power level over 800whp with no catch cans or anything anymore. regular stock PCV, nothing special. The only thing I have is the valve cover existing factory outlet on trans side opened to 5/8" and nothing attached to that either. Just a direct vent and nothing ever comes out and the intake is dry inside last time i checked.

That said, be careful where you drill new openings. Its best to just drill out the existing openings only as that is how the baffling is setup inside to accommodate for the stock position openings.

I have no troublesome blowby anymore even with my power level over 800whp with no catch cans or anything anymore. regular stock PCV, nothing special. The only thing I have is the valve cover existing factory outlet on trans side opened to 5/8" and nothing attached to that either. Just a direct vent and nothing ever comes out and the intake is dry inside last time i checked.

Car is stock block but typical bolt-ons BBK Full 30#. Current crankcase setup is stock routing with the PCV as well as Boomba check valve and a Saikou-Michi Dual catch can. I dont want to delete my PCV or run VTA. It seems all I need is top open up the trans side and I should be fine.

I pulled out that side nipple but am concerned that when I go to drill it I am going to run out of room since the hole is kinda close to the top of the valve cover already. Can this be done with a hand drill or does it need to be done with a drill press so it can be drilled offset?

My catch cans are 1/2" inlets so I was probably just going to use a 1/2" barb. Is this going to be enough? Any advice or things I need to take into account? I plan to drill out the baffles as well as that seems like the safest option. There are good writeups on that but I havent found anything good for drilling and taping the trans side vent.

Tom where did you get that fitting and should I go with a 5/8" instead of 1/2"? I could probably stretch the 1/2" rubber hose to fit on 5/8 if that would be better. Any advice that you have for safe and proper drilling, what size drill bit I should use, what my technique should be what tap I will need and where to get a good fitting would be much appreciated

#1003

Former Sponsor

iTrader: (31)

I honestly do not remember anymore im sorry. If you dig in this thread you might find me mentioning the ebay id's of the auctions though.

All you need is enough to relieve the pressure. Im not sure how much that is honestly, but what I did 5/8 got the job done.

The main reason for a catch can is to catch oil. Really the only place that a can is needed is between the valve cover and intake manifold, to stop oil from entering the plenum.

However you can just cap it and completely seperate the two alltogether. I have tuned cars with every combination possible, and never noticed any issues with either or routing.

Then you have the other method of a can inbetween the valve cover and intake pipe to connect the two to have a venturi type affect from the turbo vacuum'ing out the excess pressure that way.

I've done every option there was, and just ended up with what you responded to in that picture. I still use a spring on my dipstick, but one day after I checked my oil I forgot to connect it back and did around 20+ pulls at 750-800+ whp level and the dipstick did not budge at all. So I wouldnt be afraid to say this entirely cures the dipstick movement as well.

I've taken a look at my intake plenum after 500+ hard miles and no oil in it and im still using the pcv.

Pretty much everything mentioned in this thread will work, it just depends on what you want to do.

I would recommend doing what I did with the 5/8 opening on the side since it cured all my problems.

I do remember i drilled, tapped, and screwed that fitting in. I also remember taking grease on a zip tie and getting every last bit of debri out, loading it up with tons of brake cleaner and water and just really making sure i got everything out, since i did not remove baffles.

This was all done years ago when this thread was started, and im still using the same valve cover with no issues So if you do it safely you dont have to remove the baffling.

So if you do it safely you dont have to remove the baffling.

All you need is enough to relieve the pressure. Im not sure how much that is honestly, but what I did 5/8 got the job done.

The main reason for a catch can is to catch oil. Really the only place that a can is needed is between the valve cover and intake manifold, to stop oil from entering the plenum.

However you can just cap it and completely seperate the two alltogether. I have tuned cars with every combination possible, and never noticed any issues with either or routing.

Then you have the other method of a can inbetween the valve cover and intake pipe to connect the two to have a venturi type affect from the turbo vacuum'ing out the excess pressure that way.

I've done every option there was, and just ended up with what you responded to in that picture. I still use a spring on my dipstick, but one day after I checked my oil I forgot to connect it back and did around 20+ pulls at 750-800+ whp level and the dipstick did not budge at all. So I wouldnt be afraid to say this entirely cures the dipstick movement as well.

I've taken a look at my intake plenum after 500+ hard miles and no oil in it and im still using the pcv.

Pretty much everything mentioned in this thread will work, it just depends on what you want to do.

I would recommend doing what I did with the 5/8 opening on the side since it cured all my problems.

I do remember i drilled, tapped, and screwed that fitting in. I also remember taking grease on a zip tie and getting every last bit of debri out, loading it up with tons of brake cleaner and water and just really making sure i got everything out, since i did not remove baffles.

This was all done years ago when this thread was started, and im still using the same valve cover with no issues

So if you do it safely you dont have to remove the baffling.

So if you do it safely you dont have to remove the baffling.

#1004

EvoM Guru

iTrader: (1)

use a -10 to 5/8' pipe fitting. Use a unibit. The 1/2 pipe requires a 23/32" hole. You start the hole a little below the current OEM hole, and the unibit will make it easy to drill the new hole with the bit sliding into the old one. Once the unibit gets to 11/16", you'll use a standard 23/32" drill bit to drill the through the steps left by the uni bit, and get to the final size for the pipe tap. Thread it with a pipe tap and you're all set. Clean it out thoroughly (easy to do without removing the baffling with the big hole in the cover).

#1005

Evolved Member

iTrader: (41)

Thanks for the feedback guys. I've been rereading this thread as well as others regarding drilling and tapping the vc. I also have a spare cracked valve cover which is perfect to "test" on...

Tom I found the fitting you linked prior: http://www.ebay.com/itm/330327737920...p=mtr#shpCntId

What's interesting about my situation is that my car engine wise really hasnt changed since last year and this was the first time I ever popped out the dipstick. So while I know the culprit and its about time I do something about it Im just wondering why it happened now as opposed to earlier...

I have actually never used a unibit but after reading other threads that seems to be the consensus. Thank you very much for the step by step it seems very straight forward.

The only thing I am confused on is your fitting recommendation...My catch can currently has 1/2" lines on them. I do not plan on doing AN lines but rather just a barb fitting. Im thinking I could stretch the 1/2" line onto a 5/8" and itll be fine like the fitting above. Would you recommend something different? And where can I get some good quality silicon hose that is 1/2"

Tom I found the fitting you linked prior: http://www.ebay.com/itm/330327737920...p=mtr#shpCntId

What's interesting about my situation is that my car engine wise really hasnt changed since last year and this was the first time I ever popped out the dipstick. So while I know the culprit and its about time I do something about it Im just wondering why it happened now as opposed to earlier...

use a -10 to 5/8' pipe fitting. Use a unibit. The 1/2 pipe requires a 23/32" hole. You start the hole a little below the current OEM hole, and the unibit will make it easy to drill the new hole with the bit sliding into the old one. Once the unibit gets to 11/16", you'll use a standard 23/32" drill bit to drill the through the steps left by the uni bit, and get to the final size for the pipe tap. Thread it with a pipe tap and you're all set. Clean it out thoroughly (easy to do without removing the baffling with the big hole in the cover).

The only thing I am confused on is your fitting recommendation...My catch can currently has 1/2" lines on them. I do not plan on doing AN lines but rather just a barb fitting. Im thinking I could stretch the 1/2" line onto a 5/8" and itll be fine like the fitting above. Would you recommend something different? And where can I get some good quality silicon hose that is 1/2"