for anyone that has crankcase pressure issues

#1007

EvoM Guru

iTrader: (1)

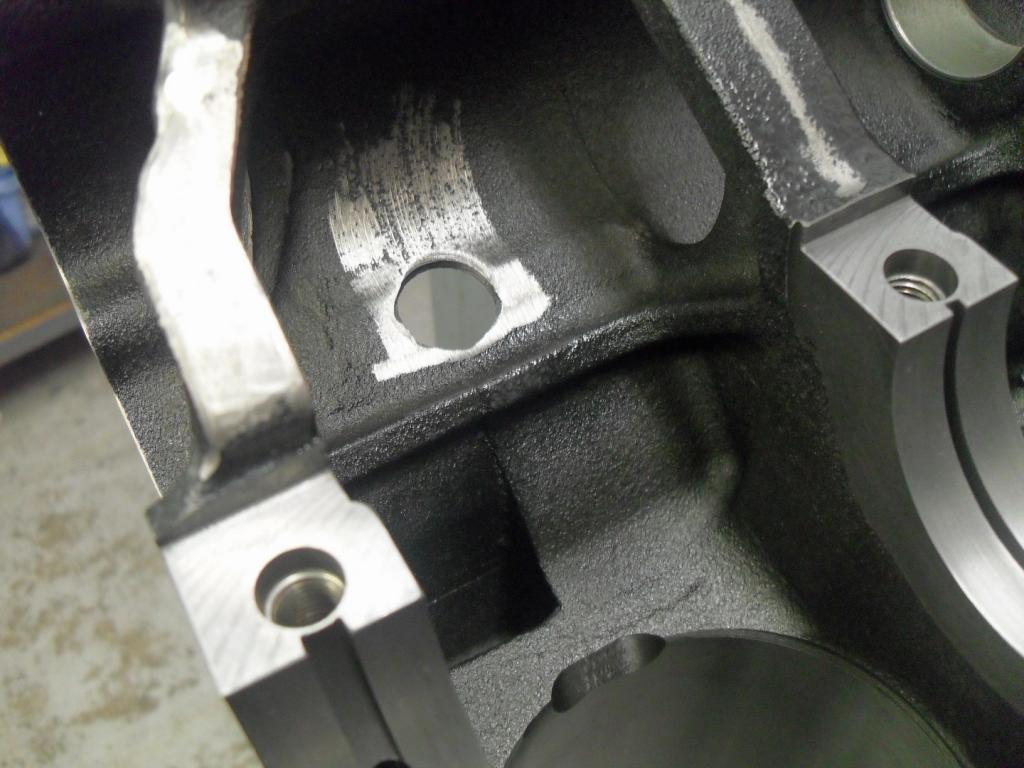

Thanks for the feedback guys. I've been rereading this thread as well as others regarding drilling and tapping the vc. I also have a spare cracked valve cover which is perfect to "test" on...

Tom I found the fitting you linked prior: http://www.ebay.com/itm/330327737920...p=mtr#shpCntId

What's interesting about my situation is that my car engine wise really hasnt changed since last year and this was the first time I ever popped out the dipstick. So while I know the culprit and its about time I do something about it Im just wondering why it happened now as opposed to earlier...

I have actually never used a unibit but after reading other threads that seems to be the consensus. Thank you very much for the step by step it seems very straight forward.

The only thing I am confused on is your fitting recommendation...My catch can currently has 1/2" lines on them. I do not plan on doing AN lines but rather just a barb fitting. Im thinking I could stretch the 1/2" line onto a 5/8" and itll be fine like the fitting above. Would you recommend something different? And where can I get some good quality silicon hose that is 1/2"

Tom I found the fitting you linked prior: http://www.ebay.com/itm/330327737920...p=mtr#shpCntId

What's interesting about my situation is that my car engine wise really hasnt changed since last year and this was the first time I ever popped out the dipstick. So while I know the culprit and its about time I do something about it Im just wondering why it happened now as opposed to earlier...

I have actually never used a unibit but after reading other threads that seems to be the consensus. Thank you very much for the step by step it seems very straight forward.

The only thing I am confused on is your fitting recommendation...My catch can currently has 1/2" lines on them. I do not plan on doing AN lines but rather just a barb fitting. Im thinking I could stretch the 1/2" line onto a 5/8" and itll be fine like the fitting above. Would you recommend something different? And where can I get some good quality silicon hose that is 1/2"

you can just use a 1/2" pipe to 1/2" barb fitting if that is what your catch can has, and you don't want to use AN fittings.

As for hose, I would go to a hydraulic/heavy equipment shop and get push lok hose. Parker and Aeroquip make it, its good stuff.

#1008

Evolved Member

iTrader: (41)

I dont mind doing an AN on the VC since its just a matter of buying the right fittings and I'll be tapping it anyway but dont care to modify my current catch can setup.

Can I use the push lok hose with an AN fitting on the VC side and then on the catch can side just slip it over and use a worm clamp? I dont see why not...really just looking for higher quality hose that is more flexible than the standard rubber heater hose I have on there now. The line that runs from my OCC to my pre turbo intake tube has to do a 180 and I want more flexibility to ensure it doesnt get kinked...

#1009

EvoM Guru

iTrader: (1)

Boost hasnt been changed since last season. Car spikes ~30# maybe 31# in 4th. Stock ventilation BBK Full. But the dipstick didnt pop out once all last season which has been >15000mi since I dd the car and ~20 auto-x events. Maybe the o-rings have worn out but even so improving ventilation can only help.

I dont mind going 5/8" thinking it'll improve flow. The fitting Tom has (I think) is a 1/2" NPT to 5/8" barb. Im thinking I'll be able to stretch the hose over a 5/8" fitting. I know it'll bottleneck with a smaller hose but the ID of the fitting is probably larger than a 1/2" NPT to 1/2" barb.

I dont mind doing an AN on the VC since its just a matter of buying the right fittings and I'll be tapping it anyway but dont care to modify my current catch can setup.

Can I use the push lok hose with an AN fitting on the VC side and then on the catch can side just slip it over and use a worm clamp? I dont see why not...really just looking for higher quality hose that is more flexible than the standard rubber heater hose I have on there now. The line that runs from my OCC to my pre turbo intake tube has to do a 180 and I want more flexibility to ensure it doesnt get kinked...

I dont mind going 5/8" thinking it'll improve flow. The fitting Tom has (I think) is a 1/2" NPT to 5/8" barb. Im thinking I'll be able to stretch the hose over a 5/8" fitting. I know it'll bottleneck with a smaller hose but the ID of the fitting is probably larger than a 1/2" NPT to 1/2" barb.

I dont mind doing an AN on the VC since its just a matter of buying the right fittings and I'll be tapping it anyway but dont care to modify my current catch can setup.

Can I use the push lok hose with an AN fitting on the VC side and then on the catch can side just slip it over and use a worm clamp? I dont see why not...really just looking for higher quality hose that is more flexible than the standard rubber heater hose I have on there now. The line that runs from my OCC to my pre turbo intake tube has to do a 180 and I want more flexibility to ensure it doesnt get kinked...

You could probably get regular 1/2" hose onto a regular 5/8" hose barb. But push lok fittings are oversized, and the push lok hose is undersized, It typically requires heating the hose in boiling water, and using silicone spray lub to get push lok fittings together lol.

You could easily run 1/2 pipe, to 10an at the valve cover, then run a 10an hose to your catch can and then use a worm clamp to clamp it on. Make sure the hose to your turbo inlet is 1/2" or 5/8" too.

Better hose isn't necessarily more flexible. With hose, better typically means it can handle higher pressure, which means its stiffer and harder to bend. It still kinks if bent too much. I think parker actually lists a minimum bend radius for their hose.

#1010

Evolved Member

iTrader: (41)

Hmmm this is all good info to know, thanks for your continued support. You seem to be quite knowledgeable and answer all of my silly questions so thank you sir!

I've never worked with AN fitting before so learning little tidbits about various hoses and fittings is all very beneficial.

Anyway back to the topic at hand and my main objective which is releaving excess crankcase pressure so my dipstick won't pop out again. As I mentioned prior my PCV is staying and given the stock block it seems I can get away from solely opening up the trans side. But the question is how much? I know this is impossible as every situation is different and I would need to log the pressure.

In Tom's case he used a 1/2" NPT to 5/8" barb and that worked for him. But I can't seem to find the ID of said fitting. Now obviously a 5/8" barb is meant to work with 5/8" ID hose but maybe it's limited by the 1/2" NPT? Since I already have 1/2" lines I'd rather just go with 1/2" all around.

I guess what Im getting at is, is there any benefit to going with a 5/8" barb or -10AN(depending on which route I choose to go) assuming its still going to mate up to a 1/2" hose? Or why even go to 5/8" or -10AN if the fitting is still only a 1/2"NPT?

From purely a flow perspective it seems like you initial recommendation of 5/8NPT to -10an would be the best route to take. From a quick search though Im not sure said fitting exists...As I think about this I think that was just a typo because you say 1/2" pipe right after...

So if no matter what how large you make it the bottleneck is still the 1/2" fitting it seems silly to go any larger. Am I being dense here?

And then then is the hose. Depending on what fitting I go with will help dictate that decision. You make a good point about quality of hose vs flexibility and durability. I think normal heater hose has a burst pressure of >50# and I've had no issues with mine so its not from a durability perspective but rather flexibility. For that reason it seemed that something Silicone based would be my best bet.

I've never worked with AN fitting before so learning little tidbits about various hoses and fittings is all very beneficial.

Anyway back to the topic at hand and my main objective which is releaving excess crankcase pressure so my dipstick won't pop out again. As I mentioned prior my PCV is staying and given the stock block it seems I can get away from solely opening up the trans side. But the question is how much? I know this is impossible as every situation is different and I would need to log the pressure.

In Tom's case he used a 1/2" NPT to 5/8" barb and that worked for him. But I can't seem to find the ID of said fitting. Now obviously a 5/8" barb is meant to work with 5/8" ID hose but maybe it's limited by the 1/2" NPT? Since I already have 1/2" lines I'd rather just go with 1/2" all around.

I guess what Im getting at is, is there any benefit to going with a 5/8" barb or -10AN(depending on which route I choose to go) assuming its still going to mate up to a 1/2" hose? Or why even go to 5/8" or -10AN if the fitting is still only a 1/2"NPT?

From purely a flow perspective it seems like you initial recommendation of 5/8NPT to -10an would be the best route to take. From a quick search though Im not sure said fitting exists...As I think about this I think that was just a typo because you say 1/2" pipe right after...

So if no matter what how large you make it the bottleneck is still the 1/2" fitting it seems silly to go any larger. Am I being dense here?

And then then is the hose. Depending on what fitting I go with will help dictate that decision. You make a good point about quality of hose vs flexibility and durability. I think normal heater hose has a burst pressure of >50# and I've had no issues with mine so its not from a durability perspective but rather flexibility. For that reason it seemed that something Silicone based would be my best bet.

Last edited by heel2toe; Apr 14, 2015 at 08:21 PM.

#1011

EvoM Guru

iTrader: (1)

Hmmm this is all good info to know, thanks for your continued support. You seem to be quite knowledgeable and answer all of my silly questions so thank you sir!

I've never worked with AN fitting before so learning little tidbits about various hoses and fittings is all very beneficial.

Anyway back to the topic at hand and my main objective which is releaving excess crankcase pressure so my dipstick won't pop out again. As I mentioned prior my PCV is staying and given the stock block it seems I can get away from solely opening up the trans side. But the question is how much? I know this is impossible as every situation is different and I would need to log the pressure.

In Tom's case he used a 1/2" NPT to 5/8" barb and that worked for him. But I can't seem to find the ID of said fitting. Now obviously a 5/8" barb is meant to work with 5/8" ID hose but maybe it's limited by the 1/2" NPT? Since I already have 1/2" lines I'd rather just go with 1/2" all around.

I guess what Im getting at is, is there any benefit to going with a 5/8" barb or -10AN(depending on which route I choose to go) assuming its still going to mate up to a 1/2" hose? Or why even go to 5/8" or -10AN if the fitting is still only a 1/2"NPT?

From purely a flow perspective it seems like you initial recommendation of 5/8NPT to -10an would be the best route to take. From a quick search though Im not sure said fitting exists...As I think about this I think that was just a typo because you say 1/2" pipe right after...

So if no matter what how large you make it the bottleneck is still the 1/2" fitting it seems silly to go any larger. Am I being dense here?

And then then is the hose. Depending on what fitting I go with will help dictate that decision. You make a good point about quality of hose vs flexibility and durability. I think normal heater hose has a burst pressure of >50# and I've had no issues with mine so its not from a durability perspective but rather flexibility. For that reason it seemed that something Silicone based would be my best bet.

I've never worked with AN fitting before so learning little tidbits about various hoses and fittings is all very beneficial.

Anyway back to the topic at hand and my main objective which is releaving excess crankcase pressure so my dipstick won't pop out again. As I mentioned prior my PCV is staying and given the stock block it seems I can get away from solely opening up the trans side. But the question is how much? I know this is impossible as every situation is different and I would need to log the pressure.

In Tom's case he used a 1/2" NPT to 5/8" barb and that worked for him. But I can't seem to find the ID of said fitting. Now obviously a 5/8" barb is meant to work with 5/8" ID hose but maybe it's limited by the 1/2" NPT? Since I already have 1/2" lines I'd rather just go with 1/2" all around.

I guess what Im getting at is, is there any benefit to going with a 5/8" barb or -10AN(depending on which route I choose to go) assuming its still going to mate up to a 1/2" hose? Or why even go to 5/8" or -10AN if the fitting is still only a 1/2"NPT?

From purely a flow perspective it seems like you initial recommendation of 5/8NPT to -10an would be the best route to take. From a quick search though Im not sure said fitting exists...As I think about this I think that was just a typo because you say 1/2" pipe right after...

So if no matter what how large you make it the bottleneck is still the 1/2" fitting it seems silly to go any larger. Am I being dense here?

And then then is the hose. Depending on what fitting I go with will help dictate that decision. You make a good point about quality of hose vs flexibility and durability. I think normal heater hose has a burst pressure of >50# and I've had no issues with mine so its not from a durability perspective but rather flexibility. For that reason it seemed that something Silicone based would be my best bet.

1/2" NPT fittings are 1/2" ID, when referring to anything pipe, the size is the ID of the fitting or pipe itself. The ID of a 5/8" barb, and most 10an fittings is about 1/2", 10an hose is 5/8.

If I said 5/8" NPT, it was a typo. It doesn't exist lol. So I def meant 1/2 NPT. Sorry for the confusion lol.

#1012

Evolved Member

iTrader: (41)

No worries that makes perfect sense now. So I now know that it will be a 1/2"NPT which will require a 23/32 bit and your method described prior starting below with a unibit and finishing off with normal bit sounds easy enough.

But if the pipe is only 1/2" where it threads into the valve cover then why even bother going with a hose that is ID of 5/8"? Im guessing because the ID of the -8AN fitting is now less than 1/2" thus sacrifising flow?

Totally overthing this like always...

Seems like Im leaning towards doing the 1/2"NPT to -10AN to this fitting http://www.summitracing.com/parts/aer-fbl1524/overview/ and -10AN socketless hose and then just using a worm clamp to the side that mates up to my 1/2" catch can inlets.

But another side just thinks keep it simple with decent flexible hose and a barbed 5/8" to 1/2"NPT...decisions decisions

But if the pipe is only 1/2" where it threads into the valve cover then why even bother going with a hose that is ID of 5/8"? Im guessing because the ID of the -8AN fitting is now less than 1/2" thus sacrifising flow?

Totally overthing this like always...

Seems like Im leaning towards doing the 1/2"NPT to -10AN to this fitting http://www.summitracing.com/parts/aer-fbl1524/overview/ and -10AN socketless hose and then just using a worm clamp to the side that mates up to my 1/2" catch can inlets.

But another side just thinks keep it simple with decent flexible hose and a barbed 5/8" to 1/2"NPT...decisions decisions

Last edited by heel2toe; Apr 14, 2015 at 09:34 PM.

#1013

EvoM Guru

iTrader: (1)

Yes, -8an fittings are typically .370-.390 ID. The sizing for AN refers only to the hose, the fittings are always about .125 smaller ID than the hose. Just the way it is..

#1014

Evolved Member

iTrader: (41)

Thanks again. So I'm finally making some progress here...-8an is out of the question.

Still undecided whether I splurge for AN stuff or just a barbed fitting. If I go barbed fitting I'll do 5/8 though so its not bottlenecked by the fitting. That should give me close to 1/2" ID if its similar to AN in terms of size. Then I guess I could just squeeze a 1/2" hose onto the fitting and it wont limit flow since its the same ID as the fitting. I dont see how going with a 5/8" hose would make a difference with a fitting that has a smaller ID. But I also don't have a good grasp on fluid dynamics so I may not understand flow and bottlenecks properly...

However on the other end of the spectrum if I go AN it'll have to be a -10an hose so it'll work with the -10an fitting. But ~1/2" ID on the fitting and 1/2" inlet on my catch can means I may not be reaping the benefits of a larger hose.

Still undecided whether I splurge for AN stuff or just a barbed fitting. If I go barbed fitting I'll do 5/8 though so its not bottlenecked by the fitting. That should give me close to 1/2" ID if its similar to AN in terms of size. Then I guess I could just squeeze a 1/2" hose onto the fitting and it wont limit flow since its the same ID as the fitting. I dont see how going with a 5/8" hose would make a difference with a fitting that has a smaller ID. But I also don't have a good grasp on fluid dynamics so I may not understand flow and bottlenecks properly...

However on the other end of the spectrum if I go AN it'll have to be a -10an hose so it'll work with the -10an fitting. But ~1/2" ID on the fitting and 1/2" inlet on my catch can means I may not be reaping the benefits of a larger hose.

#1015

EvoM Guru

iTrader: (1)

You're thinking about it too much.

Do the 1/2" pipe to 5/8" barb, try and squeeze the 1/2" hose on it. If you can't get it on, go get a 1/2" pipe to 1/2" barb. Test it. If it alleviates your problem, great!

If it doesn't, you're going to be out about, at most, $20 for the two pipe to barb fittings, oh wel. At this point, I would switch to 10an, have your catch modded for 10an inlets and outlets, and put a 10an fitting on the turbo inlet so you have all 5/8 hose and 10an. Your valve cover will already be drilled and tapped to 1/2 pipe, so you won't have to remove it again.

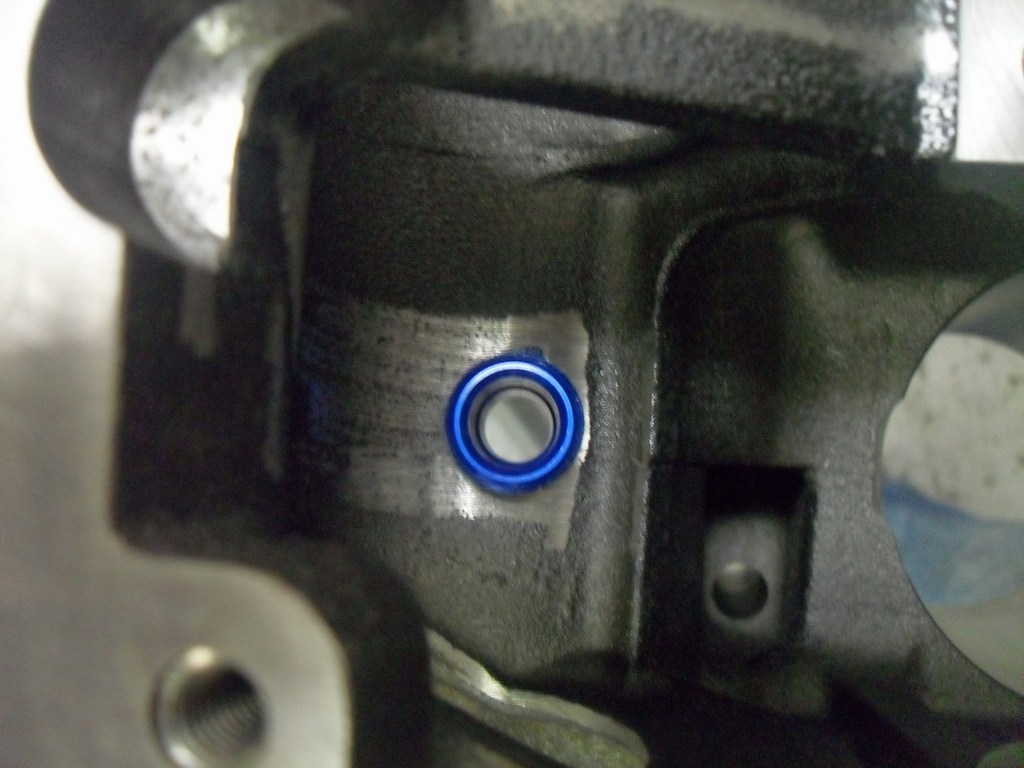

For what its worth, I see the first scenario working just fine. However, the AN fittings all Ano'd black with black hose looks pretty awesome :P. I'll take some pics of my setup and put them in here once my car goes back together.

Do the 1/2" pipe to 5/8" barb, try and squeeze the 1/2" hose on it. If you can't get it on, go get a 1/2" pipe to 1/2" barb. Test it. If it alleviates your problem, great!

If it doesn't, you're going to be out about, at most, $20 for the two pipe to barb fittings, oh wel. At this point, I would switch to 10an, have your catch modded for 10an inlets and outlets, and put a 10an fitting on the turbo inlet so you have all 5/8 hose and 10an. Your valve cover will already be drilled and tapped to 1/2 pipe, so you won't have to remove it again.

For what its worth, I see the first scenario working just fine. However, the AN fittings all Ano'd black with black hose looks pretty awesome :P. I'll take some pics of my setup and put them in here once my car goes back together.

#1016

Evolved Member

iTrader: (41)

Lol, thanks again and you're right I am thinking about this too much. It's just what I do by nature, I guess I would be considered a stable analytic...

So I finally pulled the trigger. What you just spelt out was pretty much my exact thought process. And I was about to go with the barbed fitting and then I just said f it and opted to go the AN route.

Its a better setup will look nicer and will make removing things easier down the road. One of the things I never liked about my current setup was that I welded a 1/2" pipe onto my BR intake pipe to complete my closed setup. However, where I have my cans positioned made it impossible to run the hose straight to it and caused probably too sharp of a turn and potentially kinked the line. This is why I wasn interested in a more flexible hose.

Instead since I like the idea of the AN pushlok stuff that you recommended I picked up a -10an weld ARP bung that will be welded to my intake pipe. Then I also grabbed a 120 degree pushlok fitting which should give the line an easy way to connect without kinking anything.

I also got both a 45 and a straight fitting for attaching to the valve cover so I will see which one fits better. Plus with 10' of hose if I choose to do so down the road I can always convert everything over to AN fittings. I ended up spending way more than I could have gotten away with had I just went with a simple barbed fitting but I think I'll will be happier with this setup especially if my connection to my intake is cleaner.

The only uncertainty I have now is how well the -10AN hose is going to fit on my 1/2" inlets on my catch cans but I'm sure it'll be fine as you said its tighter than other hoses and I read that it actually shrinks under pressure which I found to be interesting...

But anyway thanks again for your continued support

So I finally pulled the trigger. What you just spelt out was pretty much my exact thought process. And I was about to go with the barbed fitting and then I just said f it and opted to go the AN route.

Its a better setup will look nicer and will make removing things easier down the road. One of the things I never liked about my current setup was that I welded a 1/2" pipe onto my BR intake pipe to complete my closed setup. However, where I have my cans positioned made it impossible to run the hose straight to it and caused probably too sharp of a turn and potentially kinked the line. This is why I wasn interested in a more flexible hose.

Instead since I like the idea of the AN pushlok stuff that you recommended I picked up a -10an weld ARP bung that will be welded to my intake pipe. Then I also grabbed a 120 degree pushlok fitting which should give the line an easy way to connect without kinking anything.

I also got both a 45 and a straight fitting for attaching to the valve cover so I will see which one fits better. Plus with 10' of hose if I choose to do so down the road I can always convert everything over to AN fittings. I ended up spending way more than I could have gotten away with had I just went with a simple barbed fitting but I think I'll will be happier with this setup especially if my connection to my intake is cleaner.

The only uncertainty I have now is how well the -10AN hose is going to fit on my 1/2" inlets on my catch cans but I'm sure it'll be fine as you said its tighter than other hoses and I read that it actually shrinks under pressure which I found to be interesting...

But anyway thanks again for your continued support

#1017

EvoM Guru

iTrader: (1)

I don't know about it shrinking under pressure, but a good worm clamp will hold it on fine. Especially since there is very little pressure in those lines.

#1018

Evolved Member

iTrader: (41)

Yeah it should be fine. The only side under pressure would be coming from the IM at least until the check valve that I have and if that becomes an issue I can always purchase some sort of adapter.

But thanks again for your feedback, I appreciate it.

Oh and their website states the hose contracts but Im not sure how much of that is marketing hype...http://aeroquipperformance.com/p-240...tml#socketless

But thanks again for your feedback, I appreciate it.

Oh and their website states the hose contracts but Im not sure how much of that is marketing hype...http://aeroquipperformance.com/p-240...tml#socketless

#1019

Evolving Member

#1020

EvoM Guru

iTrader: (1)

You're going to need to baffle that, or its going to push A LOT of oil...