Help Me! I Don't Know Jack.

#1

Evolved Member

Thread Starter

Help Me! I Don't Know Jack.

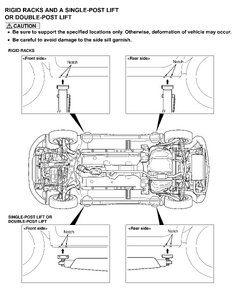

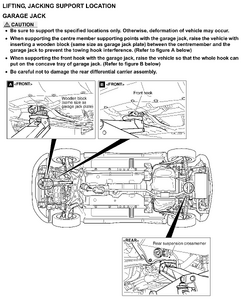

About jacks and jacking my RVR. I know how to change a flat of course but I'd like to use my floor/trolley jack rather than the scissor jack. I've seen how you can get lift pads that are used on the pinch welds, but I'd like to make my own from a hockey puck, eh? But does the scissor jack lift the car on the edge (facing down) of the pinch weld, or via the "shoulders" from which the weld projects?

#3

Evolved Member

Thread Starter

Very helpful. But I would still like to know what sort of adapter to use on the jacking notches on the sides (although I would probably use the frame spots)

#4

Evolved Member

Thread Starter

How do others jack up there OS/RVRs? At the pinch welds with factory scissor jack? Floor jack at the cross member (rear) or tow hook area (front?

#5

Ive only jacked mine up as the above diagrams shows with the scissor jack. I havent needed to get under it for anything. just doing some tires. I didnt really see any good spots when i was looking to lift mine so i stuck with the book

#6

Evolved Member

Thread Starter

My concern is the car's scissor jack wrecking the pinch weld (scratches lead to rust, etc.) I should post a pic of the welds on my 03 Dodge.  I have to figure this out....

I have to figure this out....

I have to figure this out....

I have to figure this out....

#7

Evolved Member

http://www.canadiantire.ca/en/pdp/ce...l#.VVSpXflVhBc

I use the four side anchor points. Due to the respectable ground clearance I put two 2 x 8 under the jack side by side. This prevents the piston on my jack to be pushed to the end and also prevents my garage floor from the wheel marks from the jack. The other advantage of a jack on wheels is that it will automatically roll to the position that provides a vertical lift.

One can rotate the head of the jack to align the grooves on the head with the notches on the bottom of the car. The alignment must be done carefully. Misalignment is a primary source to bend the notches and/or damage the paint. As you start lifting check the alignment and lower the jack if you notice any misalignment. I also apply a small towel to avoid any scratch on the paint. The towel is just thick enough to fit between the to metal pieces. The other key factor is picking a leveled surface for this job.

Once I lifted the car I place immediately a tire under the car (safety first).

I apologize to people with advanced mechanical skills for the elementary school level description but some of us in this forum may have never lifted a car before (or have not paid attention to the tiny details).

(for overseas members: the 2 x 8 is a wood plank with about 5 cm height and about 20 cm width, a construction material sold originally in 2.5 m lengths and in this case was cut at about 50 cm).

Trending Topics

#8

Evolved Member

Thread Starter

I have a similar jack bought from Princess Auto (like Harbor Freight for you Yanks) and it works fine. Now that I have the front/rear frame lift points I might try them, with padding of some sort on the jack of course. The rear looks best. But what I only really need is to lift the wheels to do my own summer/winter swaps. SO I am thinking I will do the "hockey puck jack pad" mod and use the pinch welds. But I need to be sure how deep to slot the puck. When I get around to actually building the puck pad I'll post a thread on it. Thanks for your info on methods!

#9

Evolved Member

Thread Starter

Well, I guess I should actually look at things before I post dumb questions! I looked at the pinch weld jacking area on the RVR and lo and behold - it is unlike most pinch weld! It actually is L-shaped so that there is a 5/8" or so flat area. And further, looking at the jack itself (Doh!) there is not deep groove common to most pinch weld jacks (like my kid's Subaru or my Dodge). Basically the jack is an X with flats about 5/8" and the four corners are shoulders to keep the jack from sliding. Making a lift puck will be super easy now!

Thread

Thread Starter

Forum

Replies

Last Post

song-b

04-06 Lancer Ralliart How To Requests / Questions / Tips

12

Mar 9, 2009 03:44 PM